Abstract

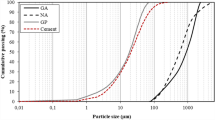

This study aims to investigate the decomposition and pozzolanic reactivity of two different clays (kaolinitic and montmorillonite) from different origins and to determine their effects after calcination on the properties of cement mortars when used to replace Portland cement partially. Mineralogical and chemical compositions of the clay samples were determined using XRD (X-ray Diffractometer) and XRF (X-ray Fluorescence) tests, respectively. TG–DTA (Thermogravimetry–Differential Thermal Analyses) was used to determine the temperature profiles and the burning temperatures of the clays. The density and fineness of the burnt clays were also determined. In order to investigate the optimum material properties, different burning temperatures and replacement levels were considered. It was found that for all temperatures, the two burnt clays possess good pozzolanic activity. The highest compressive strength and lowest water absorption capacity were achieved when the clay determined as kaolinitic was burned at 700 °C and with 10% replacement level. While for the clay determined as montmorillonite, the optimum properties were obtained at 700 °C with a 20% substitution level. Kaolinite had better pozzolanic reactivity than montmorillonite, achieving higher strength performance with lower water absorption when partially replaced with cement. Moreover, it had compressive strength values even higher than plain cement.

Similar content being viewed by others

References

Trümer, A.; Ludwig, H.-M.; Schellhorn, M.; Diedel, R.: Effect of a calcined Westerwald bentonite as supplementary cementitious material on the long-term performance of concrete. Appl. Clay Sci. 168, 36–42 (2019)

Hollanders, S.; Adriaens, R.; Skibsted, J.; Cizer, O.; Elsen, J.: Pozzolanic reactivity of pure calcined clays. Appl. Clay Sci. 132–133, 552–660 (2016)

Scrivener, K.L.; John, V.M.; Gartner, E.M.; UN Environment: Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. and Concr. Res. 114, 2–26 (2018)

Singh, M.; Grag, M.: Reactive pozzolana from Indian clays—their use in cement mortars. Cem. Concr. Res. 36, 1903–1907 (2006)

Mccarthy, M.J.; Dyer, T.D.: Pozzoalans and pozzolanic materials. In: Hewlett, P.C., Liska, M. (eds.) Lea’s Chemistry of Cement and Concrete, 5th edn., p. 370. Elsevier, Amsterdam (2019)

Fernandez, R.; Martirena, F.; Scrivener, K.L.: The origin of the pozzolanic activity of calcined clay minerals: a comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 41, 113–122 (2011)

Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F.: Potential use of Argentine kaolinite clays as pozzolanic material. Appl. Clay Sci. 101, 468–476 (2014)

Tironi, A.; Cravero, F.; Scian, A.N.; Irassar, E.F.: Pozzolanic activity of calcined halloysite-rich kaolinitic clays. Appl. Clay Sci. 147, 11–18 (2017)

Alujas, A.; Fernandez, R.; Quintana, R.; Scrivener, K.L.; Martierna, F.: Pozzolanic reactivity of low grade kaolinitic clays: influence of calcination temperature and impact of calcination products on OPC hydration. Appl. Clay Sci. 108, 94–101 (2015)

Sabir, B.B.; Wild, S.; Bai, J.: Metakaolin and calcined clays as pozzolans for concrete: a review. Cem. Concr. Compos. 23, 441–454 (2001)

Skibsted, J.; Snellings, R.: Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 124, 1–16 (2019)

Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S.: Calcined clay limestone cements (LC3). Cem. Concr. Res. 114, 49–56 (2018)

Tironi, A.; Scian, A.N.; Irassar, E.F.: Blended cements with limestone filler and kaolinitic calcined clay: filler and pozzolanic effects. J. Mater. Civ. Eng. 29(9), 04017116 (2017)

Avet, F.; Snellings, R.; Diaz, A.A.; Haha, M.B.; Scrivener, K.: Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 85, 1–11 (2016)

Avet, F.; Li, X.; Scrivener, K.: Determination of the amount of reacted metakaolin in calcined clay blends. Cem. Concr. Res. 106, 40–48 (2018)

Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G.: Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 107, 136–151 (2018)

Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K.: Limestone calcined clay cement and concrete: a state-of-the-art review. Cem. Concr. Res. 149, 106564 (2021)

Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Al-Mandhari, O.; Al-Saidi, W.; Al-Maqbali, M.; Al-Hosni, H.; Ghaffar, S.H.: 3D printing of limestone-calcined clay cement: a review of its potential implementation in the construction industry. Results Eng. 18, 101115 (2023)

European Committee for Standardization: Cement-Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Europe, EN 197-1 (2000)

European Committee for Standardization: Methods of Test Cement-Part 1: Determination of Strength. Europe, EN 196-1 (2005)

American Society for Testing and Materials: Standard Test Method for Density of Hydraulic Cement. U.S., ASTM C-188 (1995)

American Society of Testing and Materials: Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for use in Portland Cement Concrete. U.S., ASTM C-311 (2002)

American Society of Testing and Materials: Standard Test Method for Fineness of Hydraulic Cement by the 45-μm (No. 325) Sieve. U.S., ASTM C-430 (1996)

Seiffarth, T.; Hohmann, M.; Posern, K.; Kaps, C.: Effect of thermal pre-treatment conditions of common clays on the performance of clay-based geopolymeric binders. Appl. Clay Sci. 73(6), 35–41 (2013)

Tchadjie, L.N.; Ekolu, S.O.: Enhancing the reactivity of aluminosilicate materials toward geopolymer synthesis. J. Mater. Sci. 53(7), 4709–4733 (2018)

Khalifa, A.Z.; Pontikes, Y.; Elsen, J.; Cizer, Ö.: Comparing the reactivity of different natural clays under thermal and alkali activation. RILEM Tech. Lett. 40, 74–80 (2019)

Irassar, E.F.; Bonavetti, V.L.; Castellano, C.C.; Trezza, M.A.; Rahhal, V.F.; Cordoba, G.; Lemma, R.: Calcined illite-chlorite shale as supplementary cementing material: thermal treatment, grinding, color and pozzolanic activity. Appl. Clay Sci. 179, 105143 (2019)

Taylor-Lange, S.C.; Lamon, E.L.; Riding, K.A.; Juenger, M.C.: Calcined kaolinite–bentonite clay blends as supplementary cementitious materials. Appl. Clay Sci. 108, 84–93 (2015)

Mohammed, S.; Elhem, G.; Mekki, B.: Valorization of pozzolanicity of Algerian clay: optimization of the heat treatment and mechanical characteristics of the involved cement mortars. Appl. Clay Sci. 132, 711–721 (2016)

American Society of Testing and Materials: Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). U.S., ASTM C-109 (2002)

British Standards Institution: Testing Concrete, Method for Determination of Water Absorption. U.K., BS 1881: 122 (2011)

American Society for Testing and Materials: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolana for use in Concrete. U.S., ASTM C-618 (2003)

Danner, T.; Norden, G.; Justnes, H.: Characterisation of calcined raw clays suitable as supplementary cementitious materials. Appl. Clay Sci. 162, 391–402 (2018)

Cordoba, G.P.; Zito, S.V.; Sposito, R.; Rahhal, V.F.; Tironi, A.; Thienel, C.; Irassar, E.F.: Concretes with calcined clay and calcined shale: workability, mechanical, and transport properties. J. Mater. Civ. Eng. 32(8), 04020224 (2020)

Zaribaf, B.H.; Kurtis, K.E.: Admixture compatibility in metakaolin–portland-limestone cement blends. Mater. Struct. 51, 1–13 (2018)

Zaribaf, B.H.; Uzal, B.; Kurtis, K.: Compatibility of superplasticizers with limestone-metakaolin blended cementitious system. In: Calcined Clays for Sustainable Concrete: Proceedings of the 1st International Conference on Calcined Clays for Sustainable Concrete, pp. 427–434. Springer Netherlands (2015)

Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F.: Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 37, 319–327 (2013)

Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z.: Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze thaw cycles. Constr. Build. Mater. 209, 566–576 (2019)

Li, L.; Liu, W.; You, Q.; Chen, M.; Zeng, Q.; Zhou, C.; Zhang, M.: Relationships between microstructure and transport properties in mortar containing recycled ceramic powder. J. Clean. Prod. 263, 121384 (2020)

Pandey, A.; Kumar, B.: Evaluation of water absorption and chloride ion penetration of rice straw ash and microsilica admixed pavement quality concrete. Heliyon 5(8), e02256 (2019)

Güneyisi, E.; Gesoğlu, M.; Mermerdaş, K.: Improving strength, drying shrinkage, and pore structure of concrete using metakaolin. Mater. Struct. 41, 937–949 (2008)

Gleize, P.J.; Cyr, M.; Escadeillas, G.: Effects of metakaolin on autogenous shrinkage of cement pastes. Cement Concr. Compos. 29, 80–87 (2007)

Acknowledgements

The authors take this opportunity to thank Professor Mustafa Tokyay for his guidance, comments and suggestions throughout this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no competing interests regarding the publication of this paper

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Al-Noaimat, Y.A., Akis, T. Influence of Cement Replacement by Calcinated Kaolinitic and Montmorillonite Clays on the Properties of Mortars. Arab J Sci Eng 48, 14043–14057 (2023). https://doi.org/10.1007/s13369-023-08041-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08041-y