Both the turbofan and turbojet are jet engines that rely on the same principles to provide thrust.

But what makes them different from each other? Is one design better than the other?

Let’s see how the turbofan is different from a turbojet and compare the advantages and disadvantages of either system.

Key Takeaways

- Turbojet engines are commonly found in military fighter jet aircraft.

- Turbofan engines are commonly found in civilian commercial airline aircraft.

- The turbofan engine is a development of the turbojet engine and has many advantages over the turbojet.

- A turbofan makes less noise, is more efficient at lower airspeeds, uses less fuel, but requires more maintenance than a turbojet engine.

Key Differences

The turbofan engine is a development of the turbojet engine and has many advantages over the turbojet.

The turbojet is still widely used in certain applications and has its own advantages over the turbofan.

To understand the differences between the two engine types, let’s look at their applications to compare and contrast what each engine type functions better for.

Turbojet engines are found in military fighter jet aircraft. These aircraft fly fast, are loud, and do not have much range.

Turbofan engines are found in civilian commercial airline aircraft. These aircraft are relatively slower and fly farther than military jet aircraft, and also are much quieter.

Additional Components of a Turbofan Engine

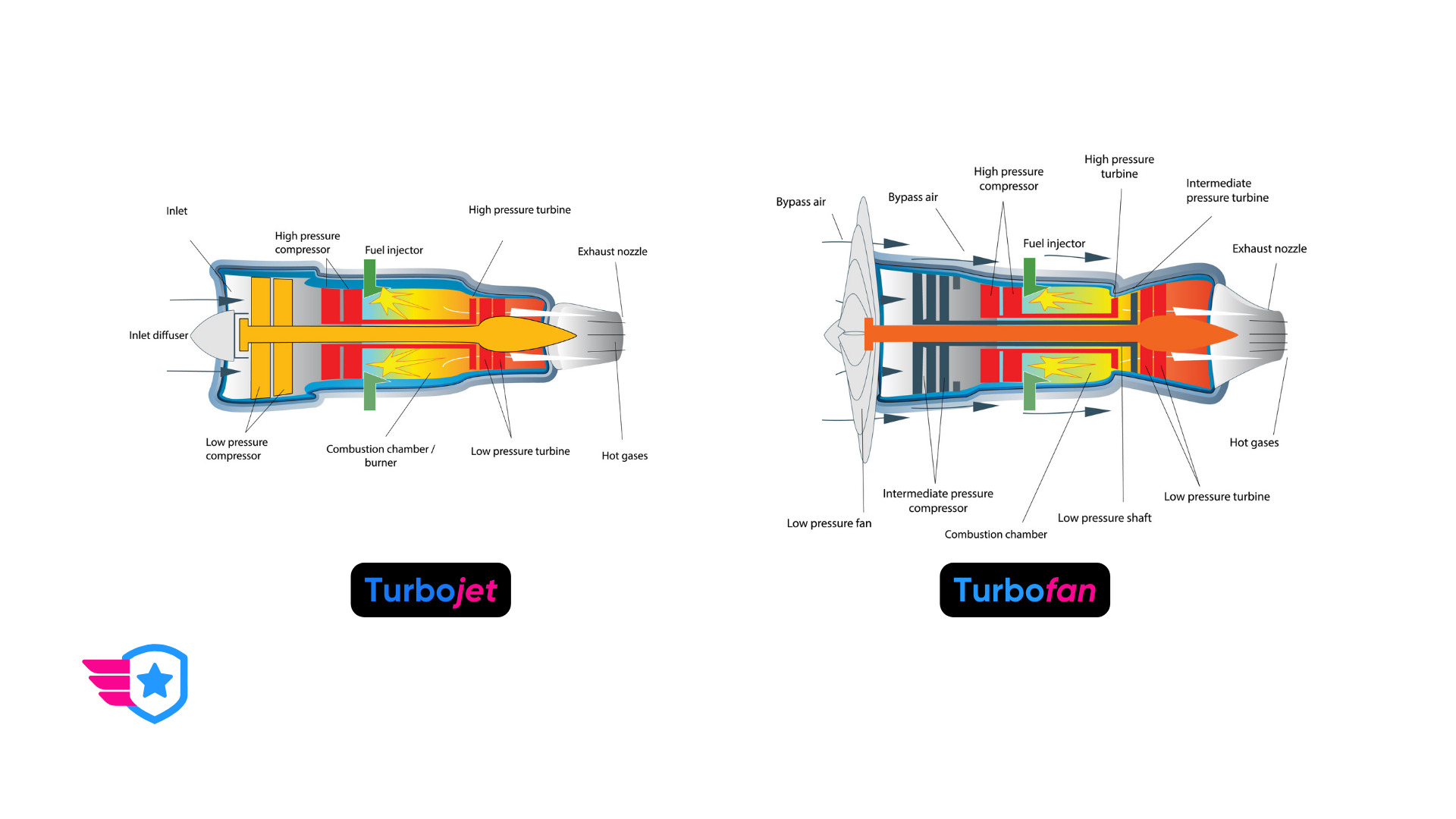

Jet engines rely on the basic principle of intake, compression, combustion, and exhaust.

However, the turbofan engine has more components than the turbojet engine.

The difference between the turbofan and turbojet is the addition of large fan blades and a nacelle around the jet engine.

In both turbofan and turbojet engines, there are sections of turbine blades behind the combustion stage that spin due to the flow of exhaust.

These turbine blades are mechanically linked to the front of the jet engine for the fan and compression blades.

In the turbofan engine, the first set of fan blades is significantly larger than the turbojet’s first set of fan blades.

In a turbofan engine, the first stage of fan blades, along with the entire jet engine, is enveloped by a nacelle which forms a case around the jet engine.

The nacelle acts as a duct for all the air that the turbofan’s large fan blade passes through, with a hot and cold section.

Hot Section

Both the turbojet and turbofan have a hot section where the compressed air is combined with jet fuel for combustion to produce exhaust and thrust.

It is called the hot section due to the high temperature from the combustion stage.

The core of the turbofan engine is the only section where air undergoes all four stages to provide thrust. This section in the turbofan is called the hot section.

The turbojet engine consists entirely of a hot section where all air that passes through the engine undergoes the four stages to provide thrust.

Cold Section

What a turbojet does not have, is a cold section.

The cold section is where the air that the large fan blades of the turbofan is pushed through.

The air that goes through this section of the nacelle does not enter the combustion stage in the engine core.

Because it does not enter the engine core, it does not get “hot” but still provides thrust as the fan blades act in a similar fashion to a propeller.

Bypass Ratio

The air that passes through the cold section is also known as bypass air.

The ratio between the mass flow rate of the bypass air to the mass flow rate entering the core is the bypass ratio.

Modern turbofan engines on commercial airline aircraft can reach a bypass ratio of up to 12:1.

This means that for every 1 kg of air that passes through the core, 12 kg of air passes through the cold section.

Turbojet engines do not have any air that flows through the engine without going through the four stages to produce thrust. This means that there is no bypass ratio.

Advantages and Disadvantages

Fuel

The turbofan engine was invented to improve the fuel consumption of the turbojet engine.

Assuming the turbofan’s core and the turbojet are the same size, the turbofan pushes more air due to the bypass air.

More thrust for the same amount of power means the turbofan does not need to burn as much fuel as the turbojet to create the same amount of thrust.

Optimal Performance

At low speeds, a propeller engine is the most efficient, while at high speeds, a jet engine is the most efficient.

Because the first stage of a turbofan engine acts in a similar fashion to a propeller, it combines the characteristics of a propeller engine combined with a jet engine.

This makes the turbofan engine much better at lower airspeeds and the turbojet better for higher airspeeds.

Noise

Another difference between the two jet engines is the noise produced.

Most of the noise produced by jet engines is created by the high-velocity exhaust air.

Turbofan engines, as mentioned earlier, have bypass ratios of up to 12:1. This bypass air has a lower velocity and averages out the hot section high-velocity air, causing a lower noise profile than a turbofan engine.

Maintenance

Because the turbofan has more components than a turbojet engine, it adds more mechanical complexity to the engine.

More parts create more components that require regular inspection, servicing, and maintenance.

The larger diameter of a turbofan, including all the additional components, increases the drag and weight of the aircraft.

Conclusion

The choice between turbofan and turbojet engines largely depends on the specific needs and objectives of an aircraft.

While turbofans are known for their fuel efficiency, quieter operations, and superior performance at lower airspeeds, they do come with the added complexity and maintenance requirements due to their additional components.

On the other hand, turbojets, while being louder and less fuel-efficient at lower speeds, excel at higher airspeeds and find prominence in high-speed military applications.

Like many technological choices, the decision is not about which design is universally better but rather which is better suited for a specific application.

Whether it’s the roar of a military jet or the hum of a commercial airliner, both turbofans and turbojets have their own unique place in the sky.