Report abnormalities and faults directly at the point of origin

Quick response to malfunctions or worker questions

Quick reaction to malfunctions or worker questions

Eliminate frequent disruptions through evaluations

A variety of faults can occur in complex manufacturing and assembly processes. From tool breakage to a lack of material at a workstation to quality problems in production — in each case, different contact persons must be alerted. Many manufacturing industrial companies still report these malfunctions in a manual, analogue process. The employee who discovers the malfunction reports the interruption to his shift supervisor. The supervisor assesses the situation and initiates the appropriate steps to remedy the situation. Usually, other employees from maintenance, materials management or quality assurance have to be contacted by phone or on foot to rectify the fault. This takes a lot of time and production can only be continued to a limited extent or, in the worst case, comes to a complete standstill.

A digital alarm management system enables a quick reaction to all production faults.

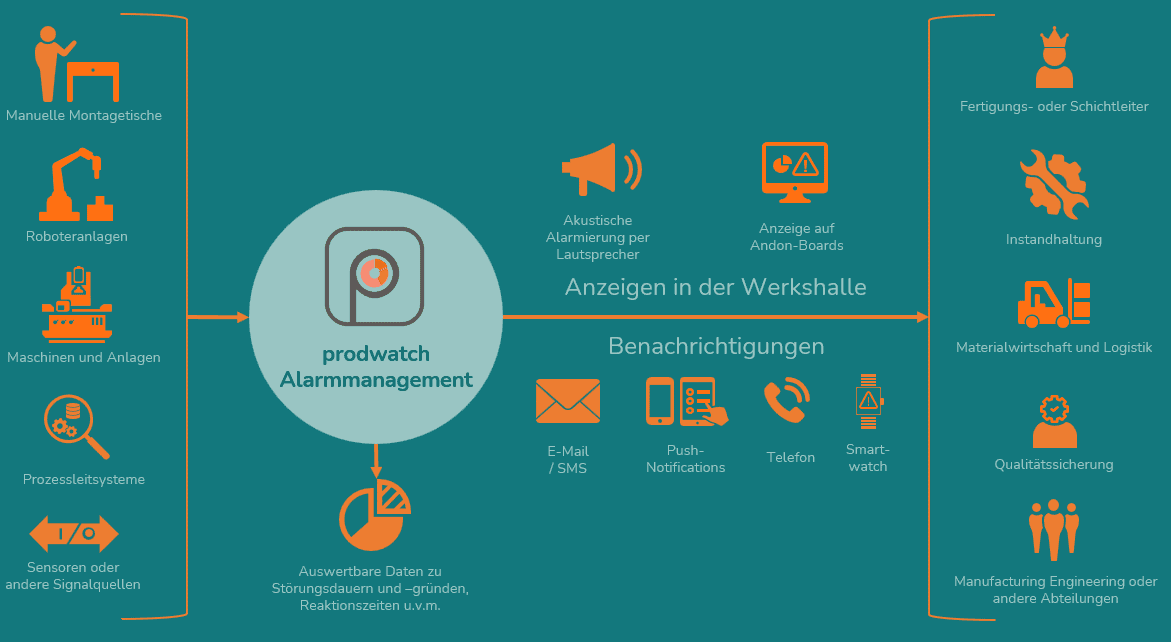

Alarm tools such as prodwatch help you to quickly recognise and remedy standstills. By using modern, digital end devices such as tablets, smartphones or smartwatches, the duration of a production disruption can be drastically reduced. Since maintenance staff, shift supervisors or other responsible persons are often on the move on the factory floor, it makes sense to deliver alerts on mobile devices such as smartphones or smartwatches. Local displays such as andon boards or traffic lights at workstations also help to maintain an overview of complex production environments.

In our free white paper on the subject of alarms in production, you will learn everything about the possibilities of fault reporting and alerting different contacts in production.

Get inspiration for your digital reporting chain!

Using our digital reporting system for malfunctions and production interruptions can save a lot of time. Employees can report the malfunctions directly at the point of origin using various input options. Ideally, there are predefined fault categories with which the employee can classify the fault directly. If such a category is selected, the right department and the right contact person can be alerted directly. This saves unnecessary walking and the false alarming of employees who have no influence on the elimination of the standstill. But machines and systems, sensor signals or process control systems can also send alarm messages.

The prodwatch alarm management system evaluates the malfunction messages and can then alert the appropriate contact persons according to the reason for the malfunction. For this purpose, prodwatch uses the integrated shift calendar as well as the user (group) management and a so-called Event & Action Centre, in which the fault categories can be assigned to individual users or user groups.

The shift or production managers alerted in this way can see the alarm on their smartwatch or other digital end devices, accept it and then react to it immediately. Furthermore, escalation management is possible, which allows unaccepted messages to be sent to the next higher escalation level. This always ensures that alarms and messages and any resulting production interruptions are responded to quickly and in a targeted manner. In addition, evaluations can be made with the resulting data, such as the times taken to rectify faults or the frequency of individual fault categories. Frequently occurring faults or downtimes with a long duration can thus be eliminated in a targeted manner and production availability can be increased.

Production faults, foreman calls or other messages can be reported directly at the workstations or the machinery and equipment via digital terminals such as tablets. The fault can already be classified here so that it is immediately clear which department should be alerted.

prodwatch processes the incoming messages using an integrated event and action logic that can be set by you and triggers appropriate actions. In addition, all data on the malfunction (e.g. time until rectification, number of malfunctions, etc.) are stored for later evaluation!

Depending on the selected reason for the disturbance, the appropriate contact person is alerted via different communication channels. The malfunctions can then be accepted or forwarded by the persons. In this way, everyone involved can see who is dealing with which message.

Faults can be acknowledged at the workstation after they have been rectified and provided with a free-text note. If a malfunction has not been accepted and/or acknowledged within a defined time, the optional escalation levels provide further attention.

In addition to alerting different contact persons, a local display on the factory floor is also useful. For this purpose, prodwatch offers you the possibility to create so-called andon boards. Here, information such as the status of individual workstations or production-relevant key figures such as OEE or scrap can be displayed. prodwatch is therefore much more than a pure alarm solution, but can be used for the complete digitalisation of production processes.

It is always difficult to measure the effects of individual systems on complex manufacturing processes. Especially with a product as versatile as prodwatch, there are countless starting points for possible savings or improvements in the processes. Some of our customers’ profitability analyses showed that the system reached the break-even point after less than a year. We have been able to determine the following empirical values with our customers in different sectors after using prodwatch.

We at apronic have already implemented many alarm applications for our customers. Therefore, we have a comprehensive know-how of what is possible and how it can be implemented. In numerous projects, a wealth of experience has grown that has been incorporated into the standard software for assembly digitisation prodwatch. This offers you a comprehensive toolbox for all the applications described for alarm systems.

We look forward to your call and to being able to bring you to new peak performances in your production in an exciting project!

apronic GmbH

Handwerker Gewerbepark 8

48282 Emsdetten