The Innovative Leader in Corrugated Stacking Machinery

Greene House Group is the exclusive representative in western United States for A.G. Stacker Inc.

Corrugated Stacking & Conveyor Solutions

XRI™ Stacker

Innovative design and heavy duty construction.

An investment that will last decades.

The XRI™ stacker is a piece of versatile corrugated stacking machinery available in the following sizes, as well as customized and jumbo sizes:

115″

Up to 13,500+ KPH

125”

Full Stack or Bundle Line

135”

4-Out Capability

XRI™ Sheet Stacker Features:

Side Catchers

Deck Lock Out System

Intelligent Safety System

Remote Diagnostic System

Proportional Valve Hydraulics

Ergonomic Operator Station

Layboy Section

Accuset Layboy Arms

Zero Crush Snubbing Wheels

Solid Aluminum Backstop

Accurack

Powered Rollout

Intuitive HMI

XRI™ Sheet Stacker Optional Upgrades:

SAMPLE QUALITY REJECTION (SQR)

HIGH-SPEED HOPPER EJECTOR (HSHE)

VISION, VENTILATED, SPLIT BACKSTOPS

CARRIAGE STYLE SNUBBING WHEELS

LEAD EDGE GUIDES

HIGH PERFORMANCE LAYBOY SECTION

PITLESS X-12 BUNDLE CONVEYING SYSTEM

LASERLINE

IES DISCONNECT HARD GUARDING

RDC INTERFACE

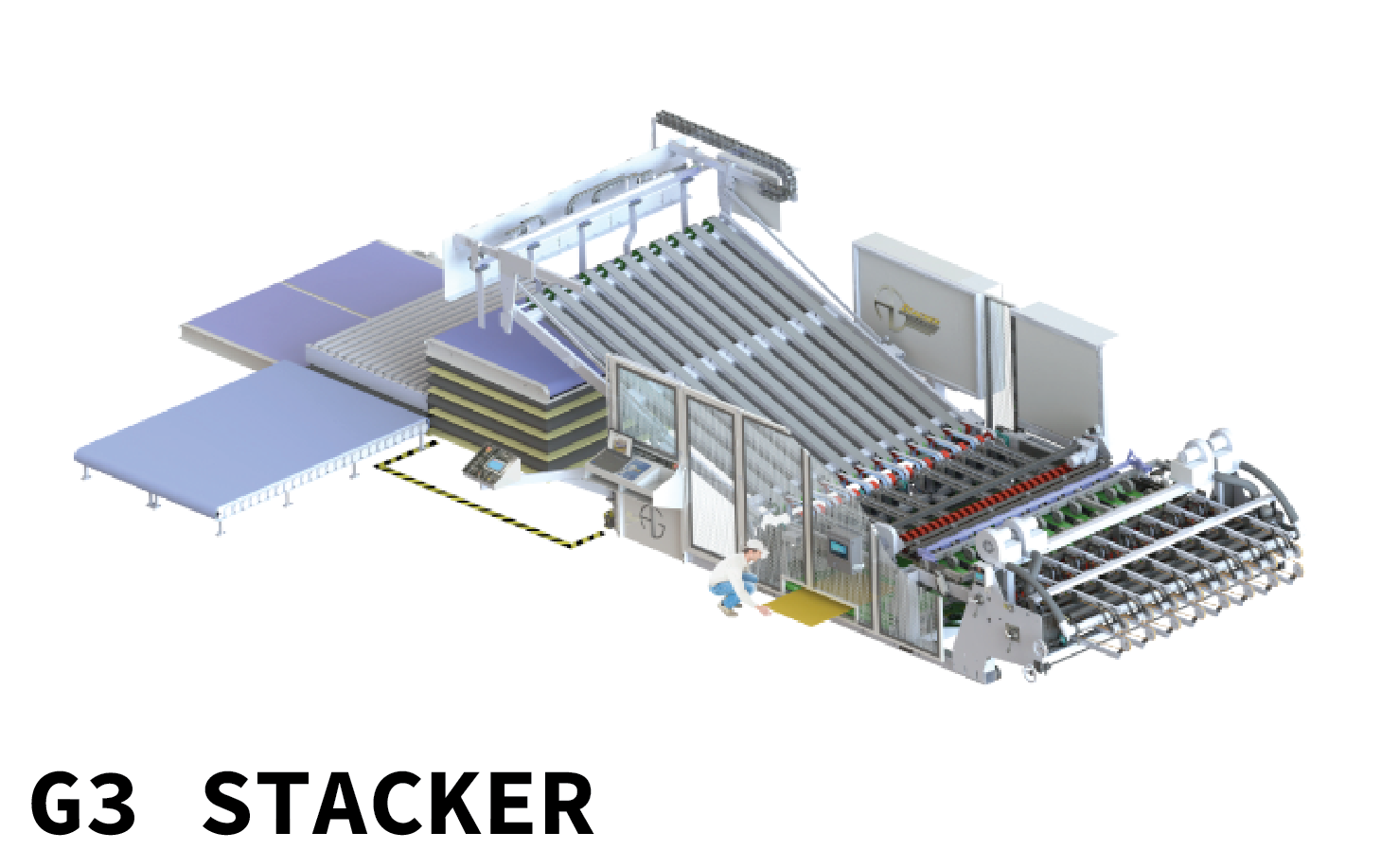

G3™ Stacker Machinery

Bringing together the most popular features for high performance into one machine.

The G3™ stacker is a piece of versatile corrugated stacking machinery available in the following sizes:

115”

125”

Up to 13,500+ KPH

Full Stack or Bundle Line

4-Out Capability

G3™ Stacker Standard Features:

High Performance Layboy

Air Operated Deck Lift

Flexi Deck

Ventilated Vision Backstop

Tampers & Dividers

Side Catchers

Remote Diagnostic System

Carriage Style Snubbing Wheels

Accumulator Back Tamping

Pivoting Hopper Guides

Scrap Release Technology

Order Memory System

G3™ Stacker Optional Upgrades

HIGH-SPEED HOPPER EJECTOR (HSHE)

SAMPLE QUALITY REJECTION (SQR)

DIVERT & SEPARATE SECTION (DSS)

AUTOMATED SYSTEM SETUP (SERVOTAMP)

Infeed Conveyor System

The Ergonomic Solution

The A.G. Stacker pitless lift table is a piece of corrugated stacking machinery that automatically adjusts top-of-stack

to the operator-specified height for sheet feeding.

Equipment Features:

Accessible Forklift Station

Customized to Plant Needs

Convenient Operator HMI

Ergonomic Sheet Fading

Indexing & Queue Modes

Equipment Advantages:

Heavy Duty

Semi-Automatic

Pitless

Flexible

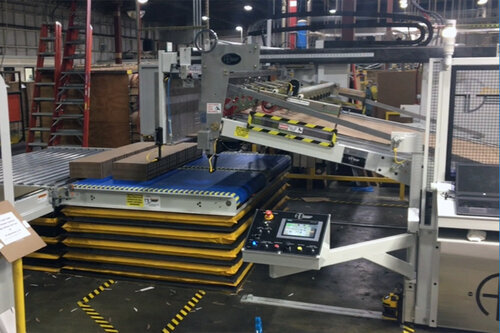

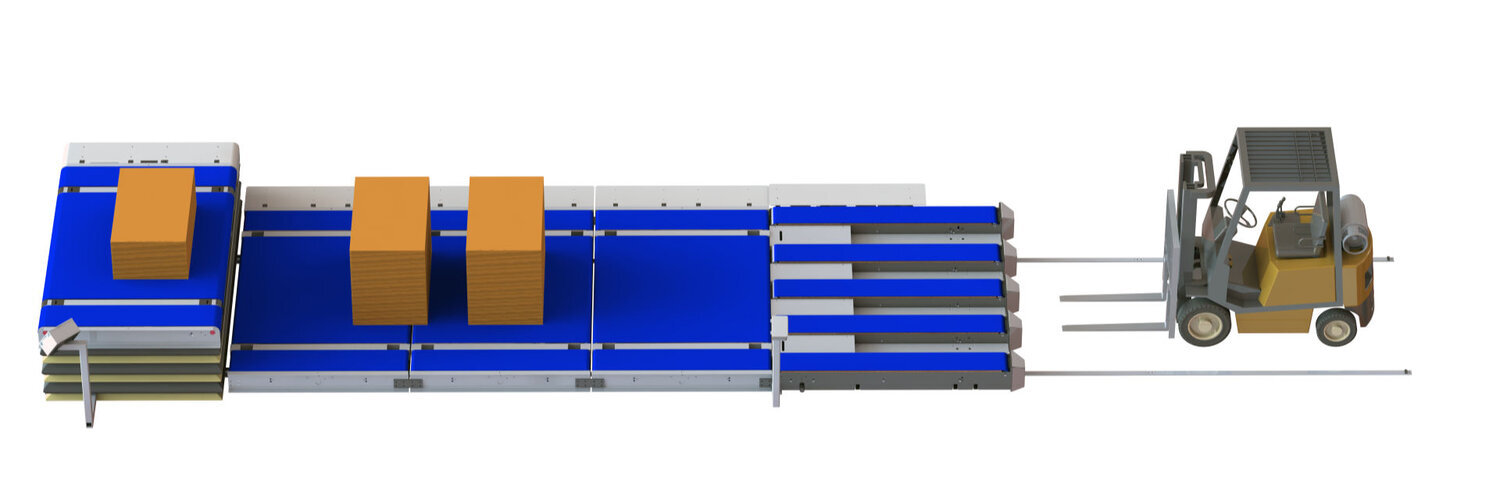

X12™ Pitless Conveyor System

Fully integrated, flexible system for conveying bundles or stacks downstream.

X12™ PITLESS LIFT CONVEYOR

No pit needed – saves time & money, less maintenance, allows for adjustment in floor plan

Reinforced and balanced for heavy loads.

Patented!

Fully Integrated: no need for another HMI

Highly Efficient: discharges in seven seconds, not 10, 15, or 20

Safety First: incorporated with stacker’s ISS to keep operators safe

Less Stress: less vertical movement for the stacker

Easily Retrofitted: add to existing stacker to improve performance

Standard Sizes: 115”, 125” – other sizes available upon request

Bundle Conveying System (BCS)

Most commonly configured as two stages: X12 + 2nd stage option (Pop Up or Ball Belt)

Retrofittable to non-A.G. Stackers (subject to engineering review)

Pop Up – Roller conveyor in the through direction with mesh pop-ups that can discharge left or right

High Speed Hopper Ejector requires BCS

Indexing Conveyor System (XCS)

Simple conveyor solution for indexing stacks after the stacker & X12 build stacks. Composed of 1-3 conveyors typically.

Floor conveyors are also available for individual purchase.

NEW! Ball mesh that allows product to be discharged in any direction, mounted on the X12 lift for convenient, reliable performance without rollers.

eXT™ Stacker Front End

Fully electric and fully integrated front end system.

This patented and patent-pending front end system allows for EXTreme RDC speeds, sheet control and scrap removal.

The eXT™ is part of the eSERIES™ equipment line.

eXT™ Stacker Front End Features:

Scrap Control System

Order Recipe Recall

Supreme Control & High Speed

Fast, Reliable Set Up

Patented & Patent-Pending

Capable of 20,000 KPH

Internal Process Cameras

No Chains or Hydraulics

Adjustable NIPs

No Pit or Floor Work

Roll Out Capable

Modular Design

Ease of Access

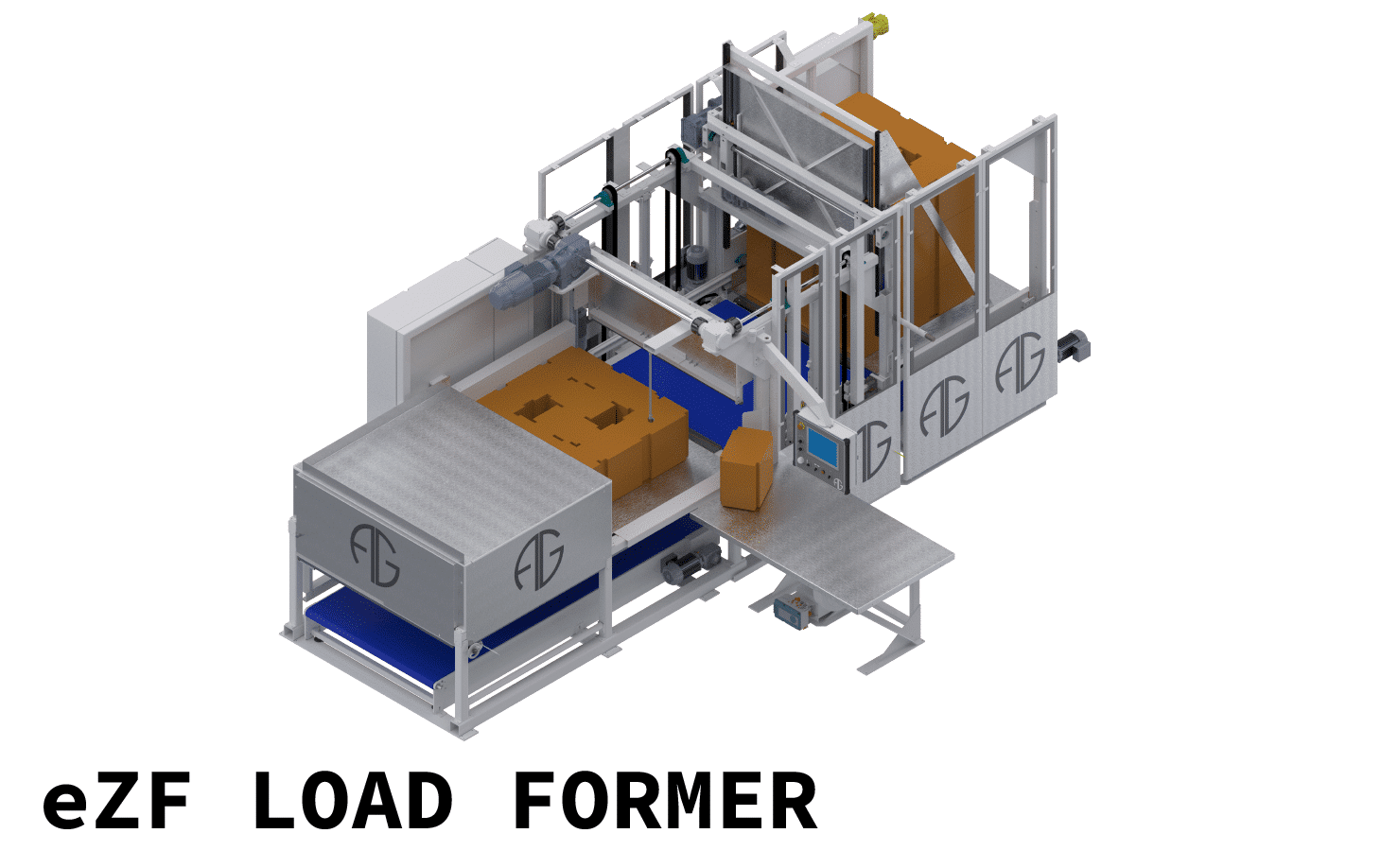

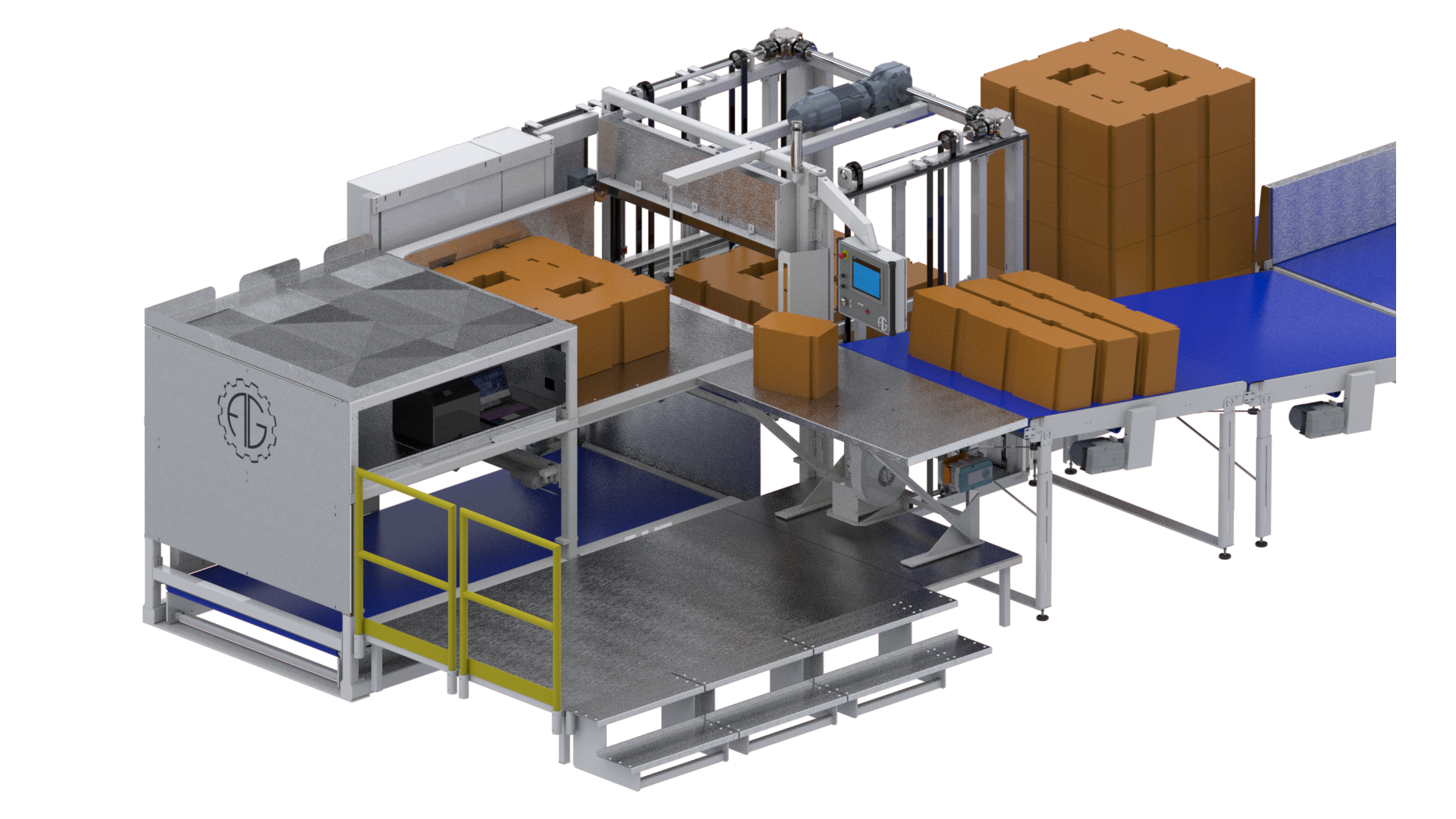

eZF™ Load Former

Semi-automatically builds loads up to 96”, without pits.

Part of the eSERIES™ equipment line of stacking machinery, the eZF™ is fully electric and fully integrated with no pits, pneumatics, or hydraulics.

The eZF™ is part of the eSERIES™ equipment line.

eZF™ Load Former Features:

No Pit

Auto Cycle Modes

Loads up to 96” height

Fully Electric

Fully Integrated

No Hydraulics or Pneumatics

Order Recipe Recall System

Fast Cycle Times

Modular Design

Integrated Safety Features

Fast, Reliable Set Up

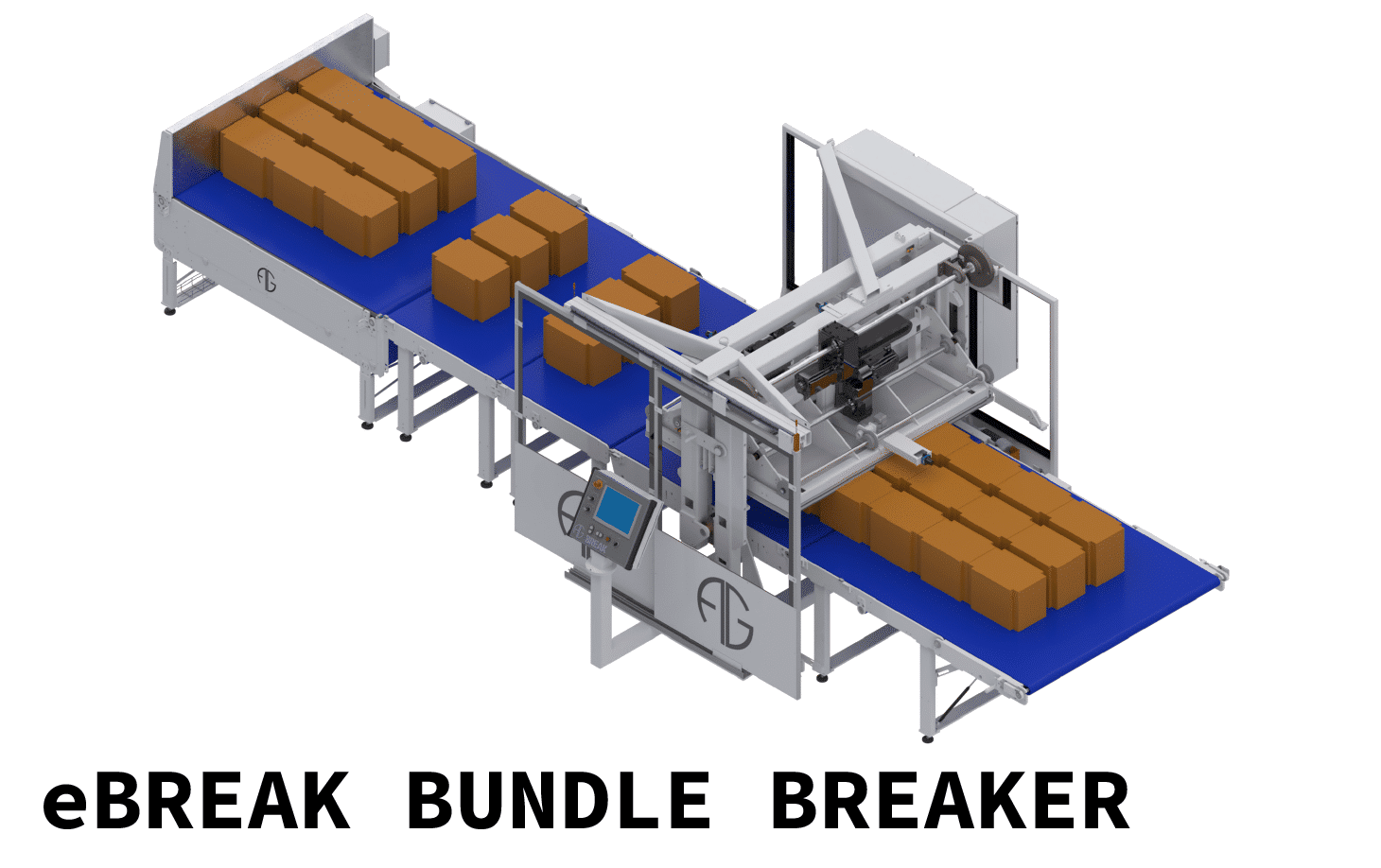

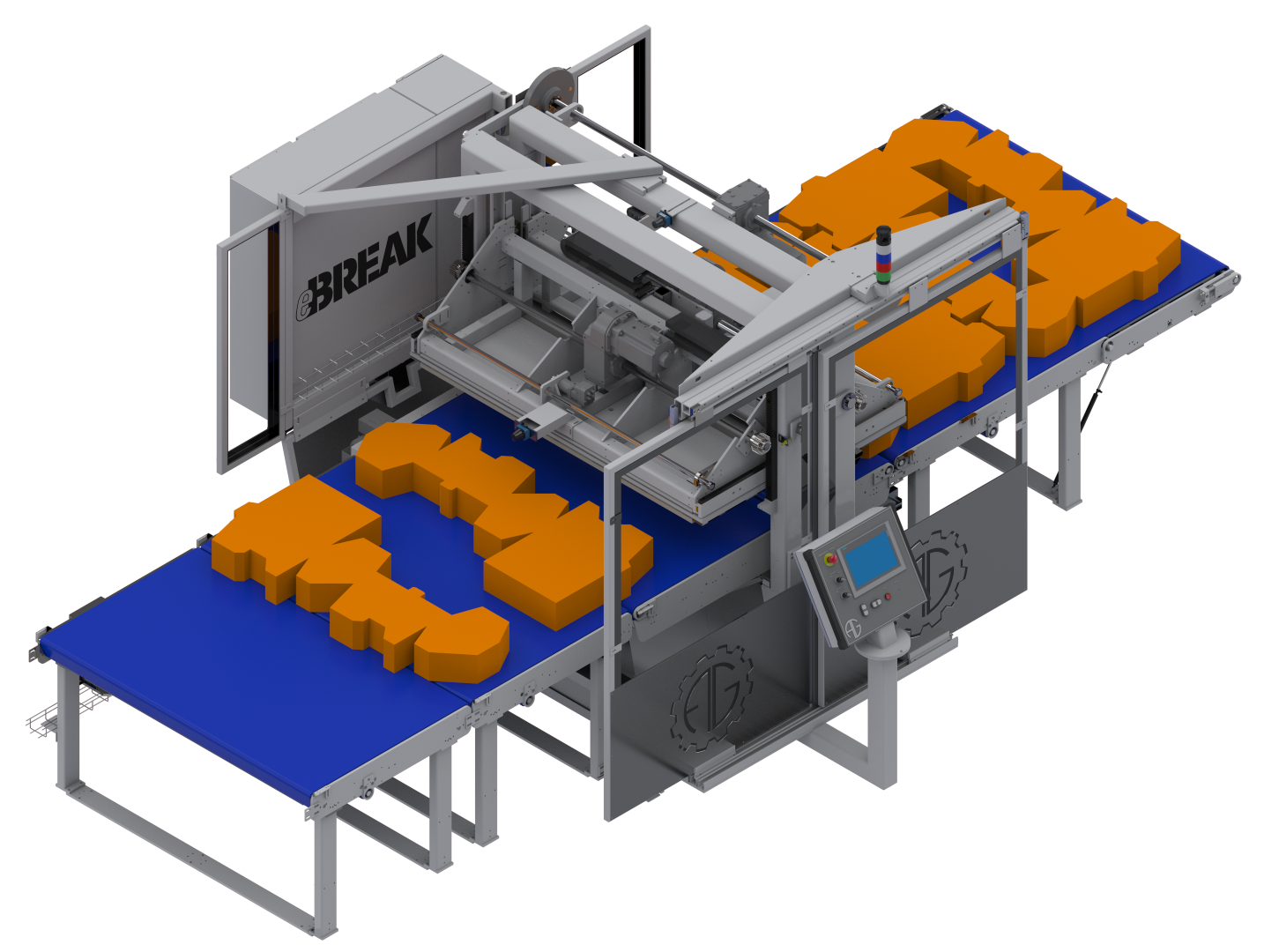

eBREAK™ Bundle Breaker

Variable, Straight, Nested, and Offset Breaks

Capable of breaks in a variety of bundle configurations and heights, the eBREAK™ Bundle Breaker is a dynamic solution to improve end-of-line efficiency within stacking machinery.

The eBREAK™ is part of the eSERIES™ equipment line.

eBREAK™ Bundle Breaker Features:

Servo-Driven Clamp & Break System

LIDAR 2D Technology

Fully Electric

Integrated Safety Features

Fast, Reliable Set Up

Order Recipe Recall System

No Hydraulics or Pneumatics

eTAMP™ ServoTamp

Easily adjust all components of the hopper using the A.G. HMI.

Don’t pause production! With the eTAMP™ system, the operator no longer needs to set up tampers in the hopper.

eTAMP™ Servo Tamp Features:

Adjustable at Full Production Speeds

Linear Motor with Multi-Axis Servo Control

Fully Electric

Automatic Backstop, Tamper and Dividers

Intuitive Operator HMI System

Fast, Reliable Set Up

Order Recipe Recall System

Increased Operator Safety

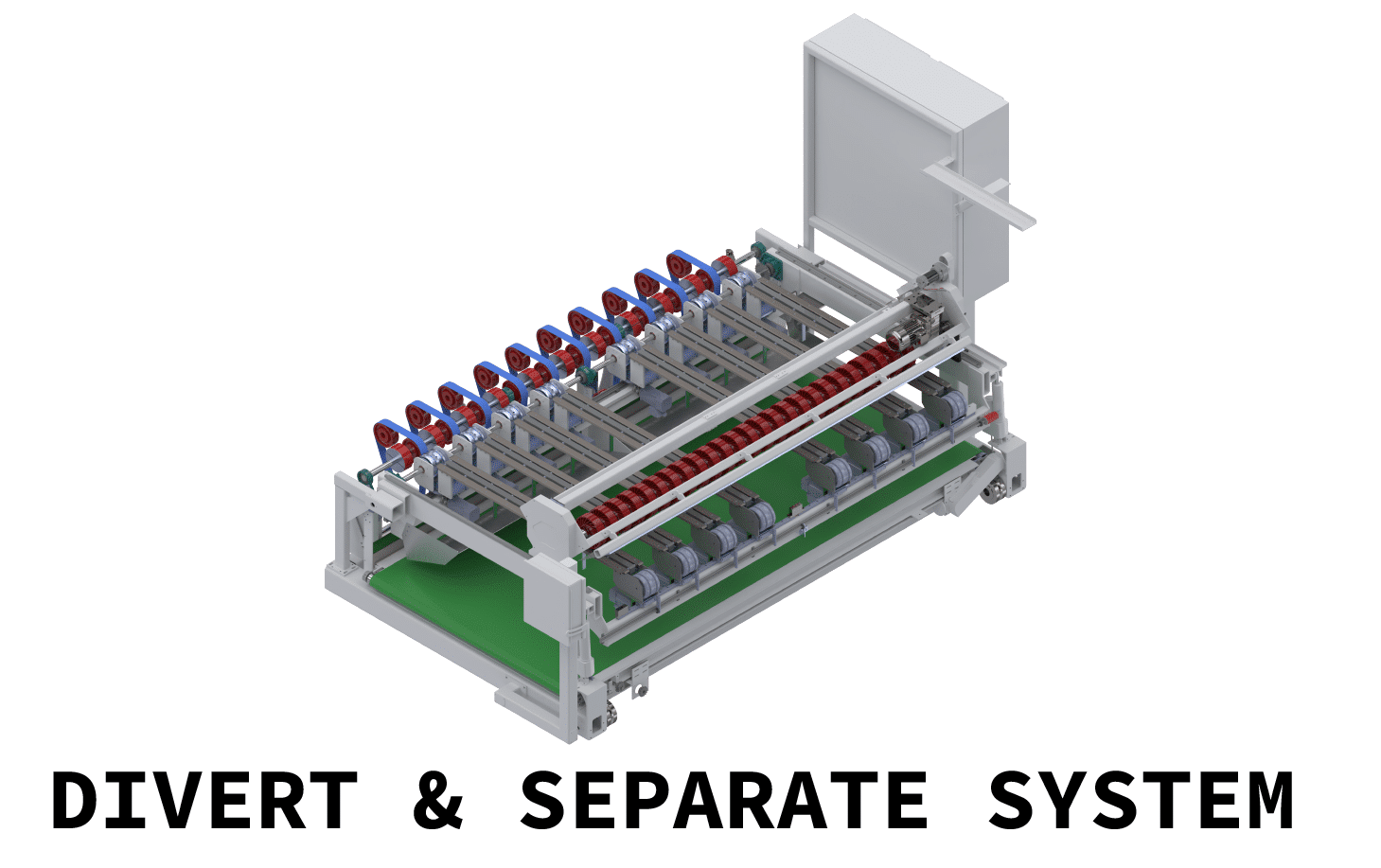

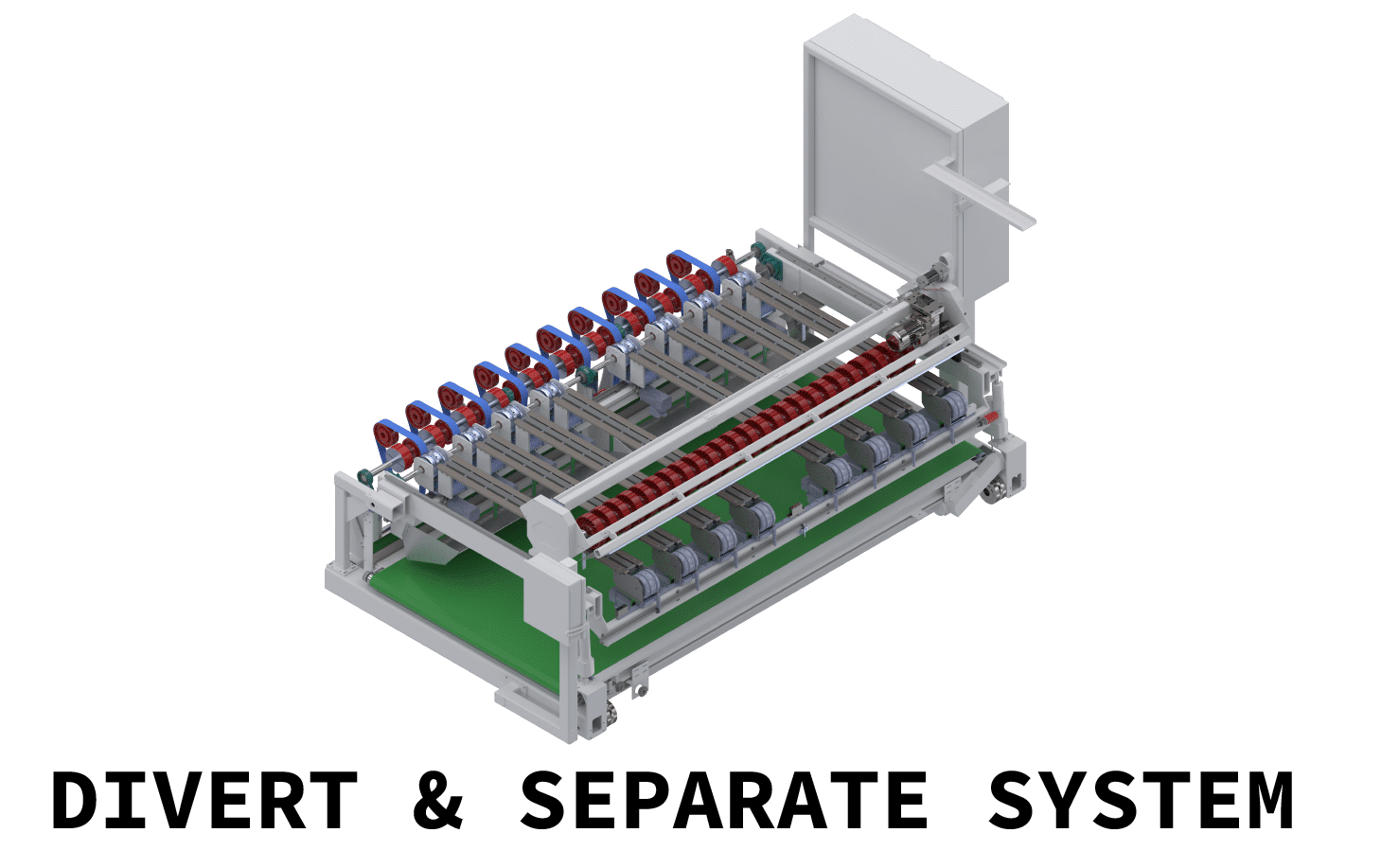

Divert & Separate System (DSS)

Automatically divert and separate at full production speeds

Diverting adjustments with the swipe of a finger! With the DSS you can automatically divert and separate at full production speeds, along with order recipe recall.

Divert & Separate System Features:

Automatic Divert & Separate Set Up

Up to 4-out Shingling Capability

Adjustable at Full Production Speeds

Order Recipe Recall System

Simple Swipe Touch Screen Set Up

Fast, Reliable Set Up

Digital Technology

GO AG™ Digital Application

With customizable collaboration, training, maintenance, and productivity capabilities, the GO AG™ Digital App equips your team to GO the long distance (and short run too) from any digitally connected device.

Your Tech. Your Way.

Upload Drawings, Manuals & FAQs

Create Maintenance Checklists

3D Equipment Models

Run Custom Training Modules

Upload Photos, Videos, & Company Files

Save Digital Work Instructions

Compatible on ALL Digital Devices

Available on Andriod and iOS for Operator Mobile Access

Desktop access for Managers and Maintenance Departments

iPad or Tablet access for Onsite Maintenance Managers

Machine HMI Internet Access

Safe and Secure Systems

User Admin Levels - Admin, Standard, Read Only

Permission Sets - By Departments, Media Libraries, Project Folders, etc.

Set User Controls - Upload, Download, etc.

No Screenshots Permitted

Data Protections - WiFi IP Whitelist, Data Encryption, Data Not Stored on Device

Digital Twin, Virtual Reality, & Augmented Reality Assistance

With the eSERIES™ equipment line preparing the way for a digital transformation, A.G. has invested in new technology to assist with the service and support of the NEW WiFi-enabled systems.

DUO™ Digital Twin Technology Features:

Risk-Free Operator Training

Hands-On Customer Collaboration

Engineering Design & Testing

Visual Planning Simulations

Troubleshooting & Maintenance

Remote Service & Support

AR & VR Features:

Maintenance & Training Simulations

Digital Twin Engineering-Customer Collaboration

Troubleshooting & Maintenance

Enhance Remote Assistance

About A.G. Stacker

A.G. Stacker has been a leader and innovator in the custom manufacturing industry since 1996. Their primary focus is the design and custom manufacturing of industrial stacking machinery for corrugated sheet operations. In 2000, they built their first RDC stacker, the AGS 2000, along with retrofitting many existing stackers with the upgrades & rebuilds the industry needed. A.G.’s mission has always been “Committed to Innovation” and as the industry changes, A.G. will continue to provide the automation and customization that plant managers and owners need.