Precision Coating Co., Inc. (Precision Coating) is ISO 14001:2015 Certified

ISO 14001 – Precision Coating Environmental Policy

Precision Coating is committed to protecting the local and global environment of the earth. To minimize environmental impacts concerning our activities, products, and services, we shall:

- Comply with applicable legal requirements and other requirements to which the Company subscribes which relate to its environmental aspects.

- To include the consideration of environmental issues in all business strategies and initiatives.

- Commit to ensure that protection of the environment is firmly embedded in both the company’s culture and all employees’ mindsets and endeavor to influence suppliers and customers in a similar strategic environmental manner.

- Prevent pollution, reduce waste, and minimize the consumption of resources.

- Protect the health and safety of our employees, neighbors, suppliers, and customers.

- Consider the wider global impact of all our activities including those of our suppliers’ customers and other stakeholders.

- Educate, train, and motivate employees to carry out tasks in an environmentally responsible manner and ensure that a continuous professional development strategy remains core to our business goals.

- Encourage environmental protection among suppliers and subcontractors.

- To investigate the feasibility of influencing its suppliers, customers and third parties with consideration to life cycle impacts of their aspects and activities.

- Encourage and enhance biodiversity and ecology.

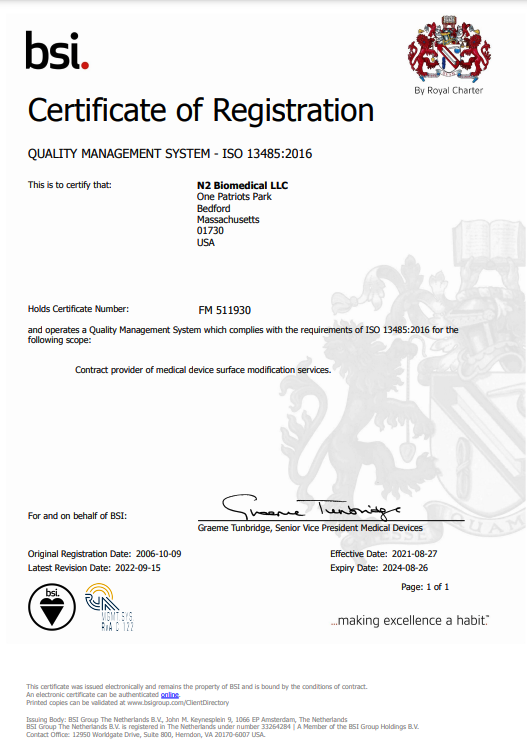

Precision Coating Co., Inc. (Precision Coating), N2 Biomedical, and Providence Texture are ISO-13485-2016 Certified

Precision Coating is committed to the highest quality customer and product service.

We hold certificates of registration for ISO 13485:2016. These certifications ensure Precision Coating’s ongoing commitment to continual improvement, customer satisfaction, and sustainability in medical applications, military applications, and commercial applications.

FDA approves Precision Coating’s MICRALOX® for use in repeat-use food processing

The U.S. Food and Drug Administration (FDA), Center for Food Safety & Applied Nutrition recently approved the use of specially sealed anodized aluminum, MICRALOX®, a proprietary hard coat product made by Precision Coating, to be suitable for food contact. The hard anodic coating will serve as the food contact surface of parts of repeat-use food processing equipment, such as molding equipment and extruders.

MIL-STD-171

MIL-STD-171 is the military standard that established the minimum requirements for finishing, and otherwise treating, metal and wood surfaces, and to serve as a general guide to the selection of suitable finishing materials, procedures, and systems.

As the MIL-STD-171 standard pertains to aluminum parts and finishes provided by Precision Coating

- MIL-STD-171, 7.2.1 calls out Anodic film on aluminum, sulfuric acid, MIL-A-8625*, Type II Class 1, nondyed

- MIL-STD-171, 7.2.2 calls out Anodic film on aluminum, sulfuric acid, MIL-A-8625,* Type II Class 2, dyed, color to be specified

- MIL-STD-171, 7.3.1 calls out Chemical film, chromate, MIL-C-5541 Class 1A, for maximum protection against corrosion, painted or unpainted

- MIL-STD-171, 7.3.3 calls out Chemical film, chromate, MIL-C-5541 Class 3, for protection against corrosion where low electrical resistance is required

- MIL-STD-171, 75.1 calls out Hard anodic coating on aluminum, MIL-A-8625*, Type III, Class 1 – thickness 0.002” ± 0.0002” unless otherwise specified, nondyed

- MIL-STD-171, 7.5.2 calls out Hard anodic coating on aluminum, MIL-A-8625*, Type III, Class 2 – thickness 0.002” ± 0.0002” unless otherwise specified, dyed, color to be specified.

Sanford Hard Coat

(Hard Anodize Natural and Colors)

- MIL-A-8625, Type III, Class1 AMS 2468

- MIL-A-8625, Type III, Class2 AMS 2469

- AMS-A-8625, Type III, Class1 BAC 5821

- AMS-A-8625, Type III, Class2 PS 13208

- MIL-STD 171, 7.5.1 PS 13201

- MIL-STD 171, 7.5.2 PS 13201.1

- HP 4-79

Sanford HARDLUBE® (Hard Coat w/Teflon®)

- MIL-A-63576, Type I AMS 2482

- Sulfuric Anodize ( Clear and Colors)

- MIL-A-8625 Type II, Class 1 AMS 2471

- MIL-A-8625 Type II, Class 2 AMS 2472

- AMS-A-8625, Type II, Class1 DPS-11.05

- AMS-A-8625, Type II, Class2 DPS-11.06

- MIL-STD-171, 7.2.1

- MIL-STD-171, 7.2.2

Clear and Color Anodizing to Aluminum Association (AA) & American Architectural Manufacturers Association (AAMA) finish designations

Chemical Conversion Coating (Alodine, Iridite, Chem Film)

- MIL-C-5541E, Class 1A, Class 3

- MIL-STD-171

- AMS 2473

- AMS 2474

MIL-A-8625 Aluminum Anodic Coatings

MIL-A-8625 is the military specification for anodic coatings for aluminum and aluminum alloys. This mil-spec covers the requirements for electrochemically-formed anodic coatings on aluminum and aluminum alloys for non-architectural applications. It provides details, methods, and procedures for these various coatings. MIL-A-8625 is approved for use by all Departments and Agencies of the Department of Defense.

Precision Coating’s MIL-A-8625 Anodized Aluminum Finishing

If you need to give an aluminum surface the hardness of case-hardened steel while maintaining the light-weight of aluminum, make Precision Coating your number one choice. Our custom finishes will make your surface sapphire-hard and corrosion- and abrasion-resistant, help it conduct or resist heat, give it lubricity and dielectric properties, and can even color it.

We make extensive use of the Sanford Process®, a proprietary, hard anodizing method so versatile that it enables us to hard coat virtually any alloy—including 2000 series and cast—to meet your particular requirements.

Precision Coating offers the following anodic coating types and classes:

The anodic coating types and classes that Precision Coating offers are as follows:

- MIL-A-8625, Type II, Class 1 – Sulfuric acid anodizing. Conventional coatings produced from a sulfuric acid bath. Non-dyed.

- MIL-A-8625, Type II, Class 2 – Sulfuric acid anodizing. Conventional coatings produced from a sulfuric acid bath. Dyed.

- MIL-A-8625, Type III, Class 1 – Hard anodic coatings. Non-dyed.

- MIL-A-8625, Type III, Class 2 – Hard anodic coatings. Dyed.

(Hard Anodize – Natural & Colors)

- MIL-A-8625, Type III, Class 1 AMS 2468

- MIL-A-8625, Type III, Class 2 AMS 2469

- AMS-A-8625, Type III, Class 1 BAC 5821

- AMS-A-8625, Type III, Class 2 PS 13208

- MIL-STD 171, 7.5.1 PS 13201

- MIL-STD 171, 7.5.2 PS 13201.1

- HP 4-79

(Hard Coat with Teflon®)

- MIL-A-63576, Type I

- AMS 2482

- MIL-A-8625 Type II, Class 1 AMS 2471

- MIL-A-8625 Type II, Class 2 AMS 2472

- AMS-A-8625, Type III, Class 1 DPS-11.05

- AMS-A-8625, Type III, Class 2 DPS-11.06

- MIL-STD-171, 7.2.1

- MIL-STD-171, 7.2.2