Engine Selection Guide Two-stroke MC/MC-C Engines - Fsb

Engine Selection Guide Two-stroke MC/MC-C Engines - Fsb

Engine Selection Guide Two-stroke MC/MC-C Engines - Fsb

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Two</strong>-<strong>stroke</strong> <strong>MC</strong>/<strong>MC</strong>-C <strong>Engine</strong>s<br />

This book describes the general technical features of the <strong>MC</strong> Programme<br />

This <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong> is intended as a 'tool' for assistance in the initial<br />

stages of a project.<br />

As differences may appear in the individual suppliers’ extent of delivery, please<br />

contact the relevant engine supplier for a confirmation of the actual execution and<br />

extent of delivery.<br />

For further informatoin see the Project <strong>Guide</strong> for the relevant engine type.<br />

This <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong> and most of the Project <strong>Guide</strong>s are available on a CD<br />

ROM.<br />

The data and other information given is subject to change without notice.<br />

5th Edition<br />

February 2000

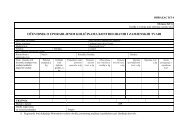

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong> Data<br />

<strong>Engine</strong> Power<br />

The table contains data regarding the engine power,<br />

speed and specific fuel oil consumption of the engines<br />

of the <strong>MC</strong> Programme.<br />

<strong>Engine</strong> power is specified in both BHP and kW, in<br />

rounded figures, for each cylinder number and layout<br />

points L1, L2, L3 and L4:<br />

L1 designates nominal maximum continuous rating<br />

(nominal <strong>MC</strong>R), at 100% engine power and 100%<br />

engine speed.<br />

L2, L3 and L4 designate layout points at the other<br />

three corners of the layout area, chosen for easy reference.<br />

Power<br />

L3<br />

L4<br />

Speed<br />

Fig. 1.01: Layout diagram for engine power and speed<br />

Overload corresponds to 110% of the power at<br />

<strong>MC</strong>R, and may be permitted for a limited period of<br />

one hour every 12 hours.<br />

The engine power figures given in the tables remain<br />

valid up to tropical conditions at sea level, ie.:<br />

Blower inlet temperature . . . . . . . . . . . . . . . . 45 °C<br />

Blower inlet pressure. . . . . . . . . . . . . . . 1000 mbar<br />

Seawater temperature . . . . . . . . . . . . . . . . . . 32 °C<br />

L1<br />

L2<br />

Specific fuel oil consumption (SFOC)<br />

Specific fuel oil consumption values refer to brake<br />

power, and the following reference conditions:<br />

ISO 3046/1-1986:<br />

Blower inlet temperature . . . . . . . . . . . . . . . . 25 °C<br />

Blower inlet pressure. . . . . . . . . . . . . . . 1000 mbar<br />

Charge air coolant temperature. . . . . . . . . . . 25 °C<br />

Fuel oil lower calorific value . . . . . . . . 42,700 kJ/kg<br />

(10,200 kcal/kg)<br />

Although the engine will develop the power specified<br />

up to tropical ambient conditions, the specific<br />

fuel oil consumption varies with ambient conditions<br />

and fuel oil lower calorific value. For calculation of<br />

these changes, see section 2.<br />

SFOC guarantee<br />

The figures given in this project guide represent the<br />

values obtained when the engine and turbocharger<br />

are matched with a view to obtaining the lowest<br />

possible SFOC values and fulfilling the IMO NO x<br />

emission limitations.<br />

The Specific Fuel Oil Consumption (SFOC) is guaranteed<br />

for one engine load (power-speed combination),<br />

this being the one in which the engine is optimised.<br />

The guarantee is given with a margin of 5%.<br />

As SFOC and NO x are interrelated parameters, an<br />

engine offered without fulfilling the IMO NO x limitations<br />

is subject to a tolerance of only 3% of the<br />

SFOC.<br />

Lubricating oil data<br />

The cylinder oil consumption figures stated in the<br />

tables are valid under normal conditions.<br />

During running-in periods and under special conditions,<br />

feed rates of up to 1.5 times the stated values<br />

should be used.<br />

430100 400 198 22 27<br />

1.01

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

The engine types of the <strong>MC</strong> programme are<br />

identified by the following letters and figures<br />

6<br />

S 70 <strong>MC</strong> - C<br />

Fig. 1.02: <strong>Engine</strong> type designation<br />

Design<br />

Concept<br />

<strong>Engine</strong> programme<br />

Diameter of piston in cm<br />

Stroke/bore ratio<br />

Number of cylinders<br />

C Compact engine<br />

S Stationary plant<br />

C Camshaft controlled<br />

E Electronic controlled (Intelligent <strong>Engine</strong>)<br />

S Super long <strong>stroke</strong> approximately 4.0<br />

L Long <strong>stroke</strong> approximately 3.2<br />

K Short <strong>stroke</strong> approximately 2.8<br />

178 34 39-1.0<br />

430100 400 198 22 27<br />

1.02

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

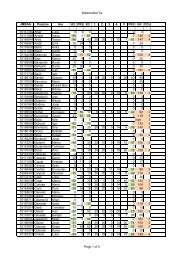

<strong>Engine</strong><br />

type<br />

Layout<br />

point<br />

<strong>Engine</strong><br />

speed<br />

Mean<br />

effective<br />

430100 400 198 22 27<br />

1.03<br />

Power KW<br />

BHP<br />

Number of cylinders<br />

r/min<br />

pressure<br />

bar 4 5 6 7 8 9 10 11 12<br />

K98<strong>MC</strong> L1 94 18.2<br />

34320<br />

46680<br />

40040<br />

54460<br />

45760<br />

62240<br />

51480<br />

70020<br />

57200<br />

77800<br />

62920<br />

85580<br />

68640<br />

93360<br />

Bore<br />

980 mm<br />

L2 94 14.6<br />

27480<br />

37320<br />

32060<br />

43540<br />

36640<br />

49760<br />

41220<br />

55980<br />

45800<br />

62200<br />

50380<br />

68420<br />

54960<br />

74640<br />

Stroke<br />

2660 mm L3 84 18.2<br />

30660<br />

41700<br />

35770<br />

48650<br />

40880<br />

55600<br />

45990<br />

62550<br />

51110<br />

69500<br />

56210<br />

76450<br />

61320<br />

83400<br />

L4 84 14.6<br />

24540<br />

33360<br />

28630<br />

38920<br />

32720<br />

44480<br />

36810<br />

50040<br />

40900<br />

55600<br />

44990<br />

61160<br />

49080<br />

66720<br />

K98<strong>MC</strong>-C L1 104 18.2<br />

34260<br />

46560<br />

39970<br />

54320<br />

45680<br />

62080<br />

51390<br />

69840<br />

57100<br />

77600<br />

62810<br />

85360<br />

68520<br />

93120<br />

Bore<br />

980 mm<br />

L2 104 14.6<br />

27420<br />

37260<br />

31990<br />

43470<br />

36560<br />

49680<br />

41130<br />

55890<br />

45700<br />

62100<br />

50270<br />

68310<br />

54840<br />

74520<br />

Stroke<br />

2400 mm L3 94 18.2<br />

30960<br />

42120<br />

36120<br />

49140<br />

41280<br />

56160<br />

46440<br />

63180<br />

51600<br />

70200<br />

56760<br />

77220<br />

61920<br />

84240<br />

L4 94 14.6<br />

24780<br />

33720<br />

28910<br />

39270<br />

33040<br />

44880<br />

37170<br />

50490<br />

41300<br />

56100<br />

45430<br />

61710<br />

49560<br />

67320<br />

S90<strong>MC</strong>-C L1 76 19.0<br />

29340<br />

39900<br />

34230<br />

46550<br />

39120<br />

53200<br />

44010<br />

59850<br />

Bore<br />

900 mm<br />

L2 76 15.2<br />

23520<br />

31980<br />

27440<br />

37300<br />

31360<br />

42640<br />

35280<br />

47970<br />

Stroke<br />

3188 mm L3 61 19.0<br />

23580<br />

32060<br />

27510<br />

37400<br />

31440<br />

42750<br />

35370<br />

48090<br />

L4 61 15.2<br />

18840<br />

25610<br />

21980<br />

29880<br />

25120<br />

34150<br />

28260<br />

38420<br />

L90<strong>MC</strong>-C L1 83 19.0<br />

29340<br />

39480<br />

34230<br />

46480<br />

39120<br />

53120<br />

44010<br />

59760<br />

48900<br />

66400<br />

53790<br />

73040<br />

58680<br />

79680<br />

Bore<br />

900 mm<br />

L2 83 12.2<br />

18780<br />

25500<br />

21910<br />

29750<br />

25040<br />

34000<br />

28170<br />

38250<br />

31300<br />

42500<br />

34430<br />

46750<br />

37560<br />

51000<br />

Stroke<br />

2916 mm L3 62 19.0<br />

21900<br />

29760<br />

25550<br />

34720<br />

29200<br />

39680<br />

32850<br />

44640<br />

36500<br />

49600<br />

40150<br />

54560<br />

43800<br />

59520<br />

L4 62 12.2<br />

14040<br />

19080<br />

16380<br />

22260<br />

18720<br />

25440<br />

21060<br />

28620<br />

23400<br />

31800<br />

25740<br />

34980<br />

28080<br />

38160<br />

K90<strong>MC</strong> L1 94 18.0<br />

18280<br />

24880<br />

22850<br />

31100<br />

27420<br />

37320<br />

31990<br />

43540<br />

36560<br />

49760<br />

41130<br />

55980<br />

45700<br />

62200<br />

50270<br />

68420<br />

54840<br />

74640<br />

Bore<br />

900 mm<br />

L2 94 11.5<br />

11700<br />

15920<br />

14650<br />

19900<br />

17580<br />

23880<br />

20510<br />

27860<br />

23440<br />

31840<br />

26370<br />

35820<br />

29300<br />

39800<br />

32230<br />

43780<br />

35160<br />

47760<br />

Stroke<br />

2550 mm L3 71 18.0<br />

13720<br />

18640<br />

17150<br />

23300<br />

20580<br />

27960<br />

24010<br />

32620<br />

27440<br />

37280<br />

30870<br />

41940<br />

34300<br />

46600<br />

37730<br />

51260<br />

41160<br />

55920<br />

L4 71 11.5<br />

8800<br />

11960<br />

11000<br />

14950<br />

13200<br />

17940<br />

15400<br />

20930<br />

17600<br />

23920<br />

19800<br />

26910<br />

22000<br />

29900<br />

24200<br />

32890<br />

26400<br />

35880<br />

Fig. 1.03a: Power and speed<br />

178 46 78-9.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong><br />

type<br />

Layout<br />

point<br />

<strong>Engine</strong><br />

speed<br />

Mean<br />

effective<br />

Power kW<br />

BHP<br />

Number of cylinders<br />

r/min<br />

pressure<br />

bar 4 5 6 7 8 9 10 11 12<br />

K90<strong>MC</strong>-C L1 104 18.0<br />

27360<br />

37260<br />

31920<br />

43470<br />

36480<br />

49680<br />

41040<br />

55890<br />

45600<br />

62100<br />

50160<br />

68310<br />

54720<br />

74520<br />

Bore<br />

900 mm<br />

L2 104 14.4<br />

21900<br />

29820<br />

25550<br />

34790<br />

29200<br />

39760<br />

32850<br />

44730<br />

36500<br />

49700<br />

40150<br />

54670<br />

43800<br />

59640<br />

Stroke<br />

2300 mm L3 89 18.0<br />

23280<br />

31620<br />

27160<br />

36890<br />

31040<br />

42160<br />

34920<br />

47430<br />

38800<br />

52700<br />

42680<br />

57970<br />

46560<br />

63240<br />

L4 89 14.4<br />

18600<br />

25320<br />

21700<br />

29540<br />

24800<br />

33760<br />

27900<br />

37980<br />

31000<br />

42200<br />

34100<br />

46420<br />

37200<br />

50640<br />

S80<strong>MC</strong>-C L1 76 19.0<br />

23280<br />

31680<br />

27160<br />

36960<br />

31040<br />

42240<br />

Bore<br />

800 mm<br />

L2 76 12.2<br />

14880<br />

20280<br />

17360<br />

23660<br />

19840<br />

27040<br />

Stroke<br />

3200 mm L3 57 19.0<br />

17460<br />

23760<br />

20370<br />

27720<br />

23280<br />

31680<br />

L4 57 12.2<br />

11160<br />

15180<br />

13020<br />

17710<br />

14880<br />

20240<br />

S80<strong>MC</strong> L1 79 19.0<br />

15360<br />

20880<br />

19200<br />

26100<br />

23040<br />

31320<br />

26880<br />

36540<br />

30720<br />

41760<br />

34560<br />

46980<br />

Bore<br />

800 mm<br />

L2 79 12.2<br />

9840<br />

13360<br />

12300<br />

16700<br />

14760<br />

20040<br />

17220<br />

23380<br />

19680<br />

26720<br />

22140<br />

30060<br />

Stroke<br />

3056 mm L3 59 19.0<br />

11480<br />

15600<br />

14350<br />

19500<br />

17220<br />

23400<br />

20090<br />

27300<br />

22960<br />

31200<br />

25830<br />

35100<br />

L4 59 12.2<br />

7360<br />

10040<br />

9200<br />

12550<br />

11040<br />

15060<br />

12880<br />

17570<br />

14720<br />

20080<br />

16560<br />

22590<br />

L80<strong>MC</strong> L1 93 18.0<br />

14560<br />

19760<br />

18200<br />

24700<br />

21840<br />

29640<br />

25480<br />

34580<br />

29120<br />

39520<br />

32760<br />

44460<br />

36400<br />

49400<br />

40040<br />

54340<br />

43680<br />

59280<br />

Bore<br />

800 mm<br />

L2 93 11.5<br />

9320<br />

12640<br />

11650<br />

15800<br />

13980<br />

18960<br />

16310<br />

22120<br />

18640<br />

25280<br />

20970<br />

28440<br />

23300<br />

31600<br />

25630<br />

34760<br />

27960<br />

37920<br />

Stroke<br />

2592 mm L3 70 18.0<br />

10960<br />

14880<br />

13700<br />

18600<br />

16440<br />

22320<br />

19180<br />

26040<br />

21920<br />

29760<br />

24660<br />

33480<br />

27400<br />

37200<br />

30140<br />

40920<br />

32880<br />

44640<br />

L4 70 11.5<br />

7000<br />

9520<br />

8750<br />

11900<br />

10500<br />

14280<br />

12250<br />

16660<br />

14000<br />

19040<br />

15750<br />

21420<br />

17500<br />

23800<br />

19250<br />

26180<br />

21000<br />

28560<br />

K80<strong>MC</strong>-C L1 104 18.0<br />

21660<br />

29400<br />

25270<br />

34300<br />

28880<br />

39200<br />

32490<br />

44100<br />

36100<br />

49000<br />

39710<br />

53900<br />

43320<br />

58800<br />

Bore<br />

800 mm<br />

L2 104 14.4<br />

17340<br />

23520<br />

20230<br />

27440<br />

23120<br />

31360<br />

26010<br />

35280<br />

28900<br />

39200<br />

31790<br />

43120<br />

34680<br />

47040<br />

Stroke<br />

2300 mm L3 89 18.0<br />

18540<br />

25200<br />

21630<br />

29400<br />

24720<br />

33600<br />

27810<br />

37800<br />

30900<br />

42000<br />

33990<br />

46200<br />

37080<br />

50400<br />

L4 89 14.4<br />

14820<br />

20160<br />

17290<br />

23520<br />

19760<br />

26880<br />

22230<br />

30240<br />

24700<br />

33600<br />

27170<br />

36960<br />

29640<br />

40320<br />

Fig. 1.03b: Power and speed<br />

430100 400 198 22 27<br />

1.04<br />

178 46 78-9.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong><br />

type<br />

Layout<br />

point<br />

<strong>Engine</strong><br />

speed<br />

Mean<br />

effective<br />

430100 400 198 22 27<br />

1.05<br />

Power kW<br />

BHP<br />

Number of cylinders<br />

r/min<br />

pressure<br />

bar 4 5 6 7 8 9 10 11 12<br />

S70<strong>MC</strong>-C L1 91 19.0<br />

12420<br />

16880<br />

15525<br />

21100<br />

18630<br />

25320<br />

21735<br />

29540<br />

24840<br />

33760<br />

Bore<br />

700 mm<br />

L2 91 12.2<br />

7940<br />

10800<br />

9925<br />

13500<br />

11910<br />

16200<br />

13895<br />

18900<br />

15880<br />

21600<br />

Stroke<br />

2800 mm L3 68 19.0<br />

9320<br />

12660<br />

11650<br />

15825<br />

13980<br />

18990<br />

16310<br />

22155<br />

18640<br />

25320<br />

L4 68 12.2<br />

5960<br />

8100<br />

7450<br />

10125<br />

8940<br />

12150<br />

10430<br />

14175<br />

11920<br />

16200<br />

S70<strong>MC</strong> L1 91 18.0<br />

11240<br />

15280<br />

14050<br />

19100<br />

16860<br />

22920<br />

19670<br />

26740<br />

22480<br />

30560<br />

Bore<br />

700 mm<br />

L2 91 11.5<br />

7200<br />

9760<br />

9000<br />

12200<br />

10800<br />

14640<br />

12600<br />

17080<br />

14400<br />

19520<br />

Stroke<br />

2674 mm L3 68 18.0<br />

8440<br />

11440<br />

10550<br />

14300<br />

12660<br />

17160<br />

14770<br />

20020<br />

16880<br />

22880<br />

L4 68 11.5<br />

5400<br />

7320<br />

6750<br />

9150<br />

8100<br />

10980<br />

9450<br />

12810<br />

10800<br />

14640<br />

L70<strong>MC</strong> L1 108 18.0<br />

11320<br />

15380<br />

14150<br />

19225<br />

16980<br />

23070<br />

19810<br />

26915<br />

22640<br />

30760<br />

Bore<br />

700 mm<br />

L2 108 11.5<br />

7240<br />

9840<br />

9050<br />

12300<br />

10860<br />

14760<br />

12670<br />

17220<br />

14480<br />

19680<br />

Stroke<br />

2268 mm L3 81 18.0<br />

8480<br />

11540<br />

10600<br />

14425<br />

12720<br />

17310<br />

14840<br />

20195<br />

16960<br />

23080<br />

L4 81 11.5<br />

5420<br />

7380<br />

6775<br />

9225<br />

8130<br />

10070<br />

9485<br />

12915<br />

10840<br />

14760<br />

S60<strong>MC</strong>-C L1 105 19.0<br />

9020<br />

12280<br />

11275<br />

15350<br />

13530<br />

18420<br />

15785<br />

21490<br />

18040<br />

24560<br />

Bore<br />

600 mm<br />

L2 105 12.2<br />

5780<br />

7860<br />

7225<br />

9825<br />

8670<br />

11790<br />

10115<br />

13755<br />

11560<br />

15720<br />

Stroke<br />

2400 mm L3 79 19.0<br />

6760<br />

9200<br />

8450<br />

11500<br />

10140<br />

13800<br />

11830<br />

16100<br />

13520<br />

18400<br />

L4 79 12.2<br />

4340<br />

5880<br />

5425<br />

7350<br />

6510<br />

8820<br />

7595<br />

10290<br />

8680<br />

11760<br />

S60<strong>MC</strong> L1 105 18.0<br />

8160<br />

11120<br />

10200<br />

13900<br />

12240<br />

16680<br />

14280<br />

19460<br />

16320<br />

22240<br />

Bore<br />

600 mm<br />

L2 105 11.5<br />

5240<br />

7120<br />

6550<br />

8900<br />

7860<br />

10680<br />

9170<br />

12460<br />

10480<br />

14240<br />

Stroke<br />

2292 mm L3 79 18.0<br />

6120<br />

8320<br />

7650<br />

10400<br />

9180<br />

12480<br />

10710<br />

14560<br />

12240<br />

16640<br />

L4 79 11.5<br />

3920<br />

5320<br />

4900<br />

6650<br />

5880<br />

7980<br />

6860<br />

9310<br />

7840<br />

10640<br />

Fig. 1.03c: Power and speed<br />

178 46 78-9.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong><br />

type<br />

Layout<br />

point<br />

<strong>Engine</strong><br />

speed<br />

Mean<br />

effective<br />

430100 400 198 22 27<br />

1.06<br />

Power kW<br />

BHP<br />

Number of cylinders<br />

r/min<br />

pressure<br />

bar 4 5 6 7 8 9 10 11 12<br />

L60<strong>MC</strong> L1 123 17.0<br />

7680<br />

10400<br />

9600<br />

13000<br />

11520<br />

15600<br />

13440<br />

18200<br />

15360<br />

20800<br />

Bore<br />

600 mm<br />

L2 123 10.9<br />

4920<br />

6680<br />

6150<br />

8350<br />

7380<br />

10020<br />

8610<br />

11690<br />

9840<br />

13360<br />

Stroke<br />

1944 mm L3 92 17.0<br />

5760<br />

7800<br />

7200<br />

9750<br />

8640<br />

11700<br />

10080<br />

13650<br />

11520<br />

15600<br />

L4 92 10.9<br />

3680<br />

5000<br />

4600<br />

6250<br />

5520<br />

7500<br />

6440<br />

8750<br />

7360<br />

10000<br />

S50<strong>MC</strong>-C L1 127 19.0<br />

6320<br />

8580<br />

7900<br />

10725<br />

9480<br />

12870<br />

11060<br />

15015<br />

12640<br />

17160<br />

Bore<br />

500 mm<br />

L2 127 12.2<br />

4040<br />

5500<br />

5050<br />

6875<br />

6060<br />

8250<br />

7070<br />

9625<br />

8080<br />

11000<br />

Stroke<br />

2000 mm L3 95 19.0<br />

4740<br />

6440<br />

5925<br />

8050<br />

7110<br />

9660<br />

8295<br />

11270<br />

9480<br />

12880<br />

L4 95 12.2<br />

3040<br />

4120<br />

3800<br />

5150<br />

4560<br />

6180<br />

5320<br />

7210<br />

6080<br />

8240<br />

S50<strong>MC</strong> L1 127 18.0<br />

5720<br />

7760<br />

7150<br />

9700<br />

8580<br />

11640<br />

10010<br />

13580<br />

11440<br />

15520<br />

Bore<br />

500 mm<br />

L2 127 11.5<br />

3640<br />

4960<br />

4550<br />

6200<br />

5460<br />

7440<br />

6370<br />

8680<br />

7280<br />

9920<br />

Stroke<br />

1910 mm L3 95 18.0<br />

4280<br />

5840<br />

5350<br />

7300<br />

6420<br />

8760<br />

7490<br />

10220<br />

8560<br />

11680<br />

L4 95 11.5<br />

2760<br />

3720<br />

3450<br />

4650<br />

4140<br />

5580<br />

4830<br />

6510<br />

5520<br />

7440<br />

L50<strong>MC</strong> L1 148 17.0<br />

5320<br />

7240<br />

6650<br />

9050<br />

7980<br />

10860<br />

9310<br />

12670<br />

10640<br />

14480<br />

Bore<br />

500 mm<br />

L2 148 10.9<br />

3400<br />

4640<br />

4250<br />

5800<br />

5100<br />

6960<br />

5950<br />

8120<br />

6800<br />

9280<br />

Stroke<br />

1620 mm L3 111 17.0<br />

4000<br />

5440<br />

5000<br />

6800<br />

6000<br />

8160<br />

7000<br />

9520<br />

8000<br />

10880<br />

L4 111 10.9<br />

2560<br />

3480<br />

3200<br />

4350<br />

3840<br />

5220<br />

4480<br />

6090<br />

5120<br />

6960<br />

S46<strong>MC</strong>-C L1 129 19.0<br />

5240<br />

7140<br />

6550<br />

8925<br />

7860<br />

10710<br />

9170<br />

12495<br />

10480<br />

14280<br />

Bore<br />

460 mm<br />

L2 129 15.2<br />

4200<br />

5700<br />

5250<br />

7125<br />

6300<br />

8550<br />

7350<br />

9975<br />

8400<br />

11400<br />

Stroke<br />

1932 mm L3 108 19.0<br />

4400<br />

5980<br />

5500<br />

7475<br />

6600<br />

8970<br />

7700<br />

10465<br />

8800<br />

11960<br />

L4 108 15.2<br />

3520<br />

4780<br />

4400<br />

5975<br />

5280<br />

7170<br />

6160<br />

8365<br />

7040<br />

9560<br />

Fig. 1.03d: Power and speed<br />

178 46 78-9.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong><br />

type<br />

Layout<br />

point<br />

<strong>Engine</strong><br />

speed<br />

Mean<br />

effective<br />

430100 400 198 22 27<br />

1.07<br />

Power kW<br />

BHP<br />

Number of cylinders<br />

r/min<br />

pressure<br />

bar 4 5 6 7 8 9 10 11 12<br />

S42<strong>MC</strong> L1 136 19.5<br />

4320<br />

5880<br />

5400<br />

7350<br />

6480<br />

8820<br />

7560<br />

10290<br />

8640<br />

11760<br />

9720<br />

13230<br />

10800<br />

14700<br />

11880<br />

16170<br />

12960<br />

17640<br />

Bore<br />

420 mm<br />

L2 136 15.6<br />

3460<br />

4700<br />

4325<br />

5875<br />

5190<br />

7050<br />

6055<br />

8225<br />

6920<br />

9400<br />

7785<br />

10575<br />

8650<br />

11750<br />

9515<br />

12925<br />

10380<br />

14100<br />

Stroke<br />

1764 mm L3 115 19.5<br />

3660<br />

4960<br />

4575<br />

6200<br />

5490<br />

7440<br />

6405<br />

8680<br />

7320<br />

9920<br />

8235<br />

11160<br />

9150<br />

12400<br />

10065<br />

13640<br />

10980<br />

14880<br />

L4 115 15.6<br />

2920<br />

3980<br />

3650<br />

4975<br />

4380<br />

5970<br />

5110<br />

6965<br />

5840<br />

7960<br />

6570<br />

8955<br />

7300<br />

9950<br />

8030<br />

10945<br />

8760<br />

11940<br />

L42<strong>MC</strong> L1 176 18.0<br />

3980<br />

5420<br />

4975<br />

6775<br />

5970<br />

8130<br />

6965<br />

9485<br />

7960<br />

10840<br />

8955<br />

12195<br />

9950<br />

13550<br />

10945<br />

14905<br />

11940<br />

16260<br />

Bore<br />

420 mm<br />

L2 176 11.5<br />

2540<br />

3460<br />

3175<br />

4345<br />

3810<br />

5190<br />

4445<br />

6055<br />

5080<br />

6920<br />

5715<br />

7785<br />

6350<br />

8650<br />

6985<br />

9515<br />

7620<br />

10380<br />

Stroke<br />

1360 mm L3 132 18.0<br />

2980<br />

4060<br />

3725<br />

5075<br />

4470<br />

6090<br />

5215<br />

7105<br />

5960<br />

8120<br />

6705<br />

9135<br />

7450<br />

10150<br />

8195<br />

11165<br />

8940<br />

12180<br />

L4 132 11.5<br />

1920<br />

2600<br />

2400<br />

3250<br />

2880<br />

3900<br />

3360<br />

4550<br />

3840<br />

5200<br />

4320<br />

5850<br />

4800<br />

6500<br />

5280<br />

7150<br />

5760<br />

7800<br />

S35<strong>MC</strong> L1 173 19.1<br />

2960<br />

4040<br />

3700<br />

5050<br />

4440<br />

6060<br />

5180<br />

7070<br />

5920<br />

8080<br />

6660<br />

9090<br />

7400<br />

10100<br />

8140<br />

11110<br />

8880<br />

12120<br />

Bore<br />

350 mm<br />

L2 173 15.3<br />

2380<br />

3220<br />

2975<br />

4025<br />

3570<br />

4830<br />

4165<br />

5635<br />

4760<br />

6440<br />

5355<br />

7245<br />

5950<br />

8050<br />

6545<br />

8855<br />

7140<br />

9660<br />

Stroke<br />

1400 mm L3 147 19.1<br />

2520<br />

3420<br />

3150<br />

4275<br />

3780<br />

5130<br />

4410<br />

5985<br />

5040<br />

6840<br />

5670<br />

7695<br />

6300<br />

8550<br />

6930<br />

9405<br />

7560<br />

10260<br />

L4 147 15.3<br />

2020<br />

2740<br />

2525<br />

3425<br />

3030<br />

4110<br />

3535<br />

4795<br />

4040<br />

5480<br />

4545<br />

6165<br />

5050<br />

6850<br />

5555<br />

7535<br />

6060<br />

8220<br />

L35<strong>MC</strong> L1 210 18.4<br />

2600<br />

3520<br />

3250<br />

4400<br />

3900<br />

5280<br />

4550<br />

6160<br />

5200<br />

7040<br />

5850<br />

7920<br />

6500<br />

8800<br />

7150<br />

9680<br />

7800<br />

10560<br />

Bore<br />

350 mm<br />

L2 210 14.7<br />

2080<br />

2820<br />

2600<br />

3525<br />

3120<br />

4230<br />

3640<br />

4935<br />

4160<br />

5640<br />

4680<br />

6345<br />

5200<br />

7050<br />

5720<br />

7755<br />

6240<br />

8460<br />

Stroke<br />

1050 mm L3 178 18.4<br />

2200<br />

3000<br />

2750<br />

3750<br />

3000<br />

4500<br />

3850<br />

5250<br />

4400<br />

6000<br />

4950<br />

6750<br />

5500<br />

7500<br />

6050<br />

8250<br />

6600<br />

9000<br />

L4 178 14.7<br />

1760<br />

2400<br />

2200<br />

3000<br />

2640<br />

3600<br />

3080<br />

4200<br />

3520<br />

4800<br />

3960<br />

5400<br />

4400<br />

6600<br />

4840<br />

6600<br />

5280<br />

7200<br />

S26<strong>MC</strong> L1 250 18.5<br />

1600<br />

2180<br />

2000<br />

2725<br />

2400<br />

3270<br />

2800<br />

3815<br />

3200<br />

4360<br />

3600<br />

4905<br />

4000<br />

5450<br />

4400<br />

5995<br />

4800<br />

6540<br />

Bore<br />

260 mm<br />

L2 250 14.8<br />

1280<br />

1740<br />

1600<br />

2175<br />

1920<br />

2610<br />

2240<br />

3045<br />

2560<br />

3480<br />

2880<br />

3915<br />

3200<br />

4350<br />

3520<br />

4785<br />

3840<br />

5220<br />

Stroke<br />

980 mm<br />

L3 212 18.5<br />

1360<br />

1860<br />

1700<br />

2325<br />

2040<br />

2790<br />

2380<br />

3255<br />

2720<br />

3720<br />

3060<br />

4185<br />

3400<br />

4650<br />

3740<br />

5115<br />

4080<br />

5580<br />

L4 212 14.8<br />

1100<br />

1480<br />

1375<br />

1850<br />

1650<br />

2220<br />

1925<br />

2590<br />

2200<br />

2960<br />

2475<br />

3330<br />

2750<br />

3700<br />

3025<br />

4070<br />

3300<br />

4440<br />

Fig. 1.03e: Power and speed<br />

178 46 78-9.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

g/kWh<br />

g/BHPh<br />

Lubricating oil consumption<br />

With high efficiency turbochargers System oil Cylinder oil<br />

At load layout point 100% 80%<br />

K98<strong>MC</strong><br />

and<br />

K98<strong>MC</strong>-C<br />

S90<strong>MC</strong>-C<br />

L90<strong>MC</strong>-C<br />

K90<strong>MC</strong><br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

171<br />

126<br />

162<br />

119<br />

171<br />

126<br />

162<br />

119<br />

167<br />

123<br />

160<br />

118<br />

167<br />

123<br />

160<br />

118<br />

167<br />

123<br />

155<br />

114<br />

167<br />

123<br />

155<br />

114<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

Fig. 1.04a: Fuel and lubricating oil consumption<br />

Approx.<br />

kg/cyl. 24h<br />

g/kWh<br />

g/BHPh<br />

430 100 100 198 22 28<br />

1.08<br />

165<br />

121<br />

158<br />

116<br />

165<br />

121<br />

158<br />

116<br />

165<br />

121<br />

157<br />

116<br />

165<br />

121<br />

157<br />

116<br />

165<br />

121<br />

154<br />

113<br />

165<br />

121<br />

154<br />

113<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

7.5-11<br />

7-10<br />

7-10<br />

7-10<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

0.8-1.2<br />

0.6-0.9<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

430 100 100 198 22 28<br />

1.09<br />

g/kWh<br />

g/BHPh<br />

Lubricating oil consumption<br />

With high efficiency turbochargers System oil Cylinder oil<br />

At load layout point 100% 80%<br />

K90<strong>MC</strong>-C<br />

S80<strong>MC</strong>-C<br />

S80<strong>MC</strong><br />

L80<strong>MC</strong><br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

171<br />

126<br />

165<br />

121<br />

171<br />

126<br />

165<br />

121<br />

167<br />

123<br />

155<br />

114<br />

167<br />

123<br />

155<br />

114<br />

167<br />

123<br />

155<br />

114<br />

167<br />

123<br />

155<br />

114<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

Fig. 1.04b: Fuel and lubricating oil consumption<br />

169<br />

124<br />

162<br />

119<br />

169<br />

124<br />

162<br />

119<br />

165<br />

121<br />

154<br />

113<br />

165<br />

121<br />

154<br />

113<br />

165<br />

121<br />

154<br />

113<br />

165<br />

121<br />

154<br />

113<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

Approx.<br />

kg/cyl. 24h<br />

7-10<br />

6-9<br />

6-9<br />

6-9<br />

g/kWh<br />

g/BHPh<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

With conventional<br />

turbochargers<br />

g/kWh<br />

g/BHPh<br />

With high efficiency<br />

turbochargers<br />

At load layout point 100% 80% 100% 80%<br />

K80<strong>MC</strong>-C<br />

S70<strong>MC</strong>-C<br />

S70<strong>MC</strong><br />

L70<strong>MC</strong><br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

Fig. 1.04c: Fuel and lubricating oil consumption<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

Lubricating oil consumption<br />

System oil Cylinder oil<br />

Approx.<br />

kg/cyl. 24h<br />

g/kWh<br />

g/BHPh<br />

430 100 100 198 22 28<br />

1.10<br />

171<br />

126<br />

165<br />

121<br />

171<br />

126<br />

165<br />

121<br />

169<br />

124<br />

156<br />

115<br />

169<br />

124<br />

156<br />

115<br />

169<br />

124<br />

156<br />

115<br />

169<br />

124<br />

156<br />

115<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

169<br />

124<br />

162<br />

119<br />

169<br />

124<br />

162<br />

119<br />

166<br />

122<br />

155<br />

114<br />

166<br />

122<br />

155<br />

114<br />

166<br />

122<br />

155<br />

114<br />

166<br />

122<br />

155<br />

114<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

6-9<br />

5.5-7.5<br />

5.5-7.5<br />

5.5-7.5<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

With conventional<br />

turbochargers<br />

g/kWh<br />

g/BHPh<br />

With high efficiency<br />

turbochargers<br />

At load layout point 100% 80% 100% 80%<br />

S60<strong>MC</strong>-C<br />

S60<strong>MC</strong><br />

L60<strong>MC</strong><br />

S50<strong>MC</strong>-C<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

173<br />

127<br />

160<br />

118<br />

173<br />

127<br />

160<br />

118<br />

173<br />

127<br />

160<br />

118<br />

173<br />

127<br />

160<br />

118<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

Fig. 1.05d: Fuel and lubricating oil consumption<br />

170<br />

125<br />

159<br />

117<br />

170<br />

125<br />

159<br />

117<br />

170<br />

125<br />

159<br />

117<br />

170<br />

125<br />

159<br />

117<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

Lubricating oil consumption<br />

System oil Cylinder oil<br />

Approx.<br />

kg/cyl. 24h<br />

g/kWh<br />

g/BHPh<br />

430 100 100 198 22 28<br />

1.11<br />

170<br />

125<br />

158<br />

116<br />

170<br />

125<br />

158<br />

116<br />

170<br />

125<br />

158<br />

116<br />

170<br />

125<br />

158<br />

116<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

167<br />

123<br />

156<br />

115<br />

167<br />

123<br />

156<br />

115<br />

167<br />

123<br />

156<br />

115<br />

167<br />

123<br />

156<br />

115<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

5-6.5<br />

5-6.5<br />

5-6.5<br />

4-5<br />

0.95-1.5<br />

0.7-1.1<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

With conventional<br />

turbochargers<br />

430 100 100 198 22 28<br />

1.12<br />

g/kWh<br />

g/BHPh<br />

With high efficiency<br />

turbochargers<br />

At load layout point 100% 80% 100% 80%<br />

S50<strong>MC</strong><br />

L50<strong>MC</strong><br />

S46<strong>MC</strong>-C<br />

S42<strong>MC</strong><br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

174<br />

128<br />

162<br />

119<br />

174<br />

128<br />

162<br />

119<br />

175<br />

129<br />

163<br />

120<br />

175<br />

129<br />

163<br />

120<br />

174<br />

128<br />

169<br />

124<br />

174<br />

128<br />

169<br />

124<br />

177<br />

130<br />

171<br />

126<br />

177<br />

130<br />

171<br />

126<br />

Fig. 1.05e: Fuel and lubricating oil consumption<br />

171<br />

126<br />

160<br />

118<br />

171<br />

126<br />

160<br />

118<br />

173<br />

127<br />

162<br />

119<br />

173<br />

127<br />

162<br />

119<br />

173<br />

127<br />

167<br />

123<br />

173<br />

127<br />

167<br />

123<br />

175<br />

129<br />

170<br />

125<br />

175<br />

129<br />

170<br />

125<br />

171<br />

126<br />

159<br />

117<br />

171<br />

126<br />

159<br />

117<br />

173<br />

127<br />

160<br />

118<br />

173<br />

127<br />

160<br />

118<br />

169<br />

124<br />

158<br />

116<br />

169<br />

124<br />

158<br />

116<br />

170<br />

125<br />

159<br />

117<br />

170<br />

125<br />

159<br />

117<br />

Lubricating oil consumption<br />

System oil Cylinder oil<br />

Approx.<br />

kg/cyl. 24h<br />

4-5<br />

4-5<br />

3.5-4.5<br />

3-4<br />

g/kWh<br />

g/BHPh<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

0.95-1.5<br />

0.7-1.1<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Specific fuel oil consumption<br />

g/kWh<br />

g/BHPh<br />

At load layout point 100% 80%<br />

L42<strong>MC</strong><br />

S35<strong>MC</strong><br />

L35<strong>MC</strong><br />

S26<strong>MC</strong><br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

L1<br />

L2<br />

L3<br />

L4<br />

Lubricating oil consumption<br />

With conventional turbochargers System oil Cylinder oil<br />

177<br />

130<br />

165<br />

121<br />

177<br />

130<br />

165<br />

121<br />

178<br />

131<br />

173<br />

127<br />

178<br />

131<br />

173<br />

127<br />

177<br />

130<br />

171<br />

126<br />

177<br />

130<br />

171<br />

126<br />

179<br />

132<br />

174<br />

128<br />

179<br />

132<br />

174<br />

128<br />

Fig. 1.05f: Fuel and lubricating oil consumption<br />

Approx.<br />

kg/cyl. 24h<br />

g/kWh<br />

g/BHPh<br />

430 100 100 198 22 28<br />

1.13<br />

174<br />

129<br />

163<br />

120<br />

174<br />

129<br />

163<br />

120<br />

177<br />

130<br />

171<br />

126<br />

177<br />

130<br />

171<br />

126<br />

175<br />

129<br />

170<br />

125<br />

175<br />

129<br />

170<br />

125<br />

178<br />

131<br />

173<br />

127<br />

178<br />

131<br />

173<br />

127<br />

3-4<br />

2-3<br />

2-3<br />

1.5-3<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

0.8-1.2<br />

0.6-0.9<br />

0.95-1.5<br />

0.7-1.1<br />

178 46 79-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.05: K98<strong>MC</strong> engine cross section<br />

430 100 018 198 22 29<br />

1.14<br />

178 32 80-6.1

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.06: S80<strong>MC</strong> engine cross section<br />

430 100 018 198 22 29<br />

1.15<br />

178 36 24-7.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.07: S70<strong>MC</strong>-C engine cross section<br />

178 44 14-4.1<br />

430 100 018 198 22 29<br />

1.16

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.08: S60<strong>MC</strong> engine cross section<br />

430 100 018 198 22 29<br />

1.17<br />

178 32 19-8.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.09: S50<strong>MC</strong>-C engine cross section<br />

178 16 07-0.0<br />

430 100 018 198 22 29<br />

1.18

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.10: L42<strong>MC</strong> engine cross section<br />

430 100 018 198 22 29<br />

1.19<br />

178 43 10-1.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 1.11: S26<strong>MC</strong> engine cross section<br />

430 100 018 198 22 29<br />

1.20<br />

178 42 12-5.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

2 <strong>Engine</strong> Layout and Load Diagrams<br />

Propulsion and <strong>Engine</strong> Running Points<br />

Propeller curve<br />

The relation between power and propeller speed for<br />

a fixed pitch propeller is as mentioned above described<br />

by means of the propeller law, i.e. the third<br />

power curve:<br />

Pb =cxn 3 , in which:<br />

Pb = engine power for propulsion<br />

n = propeller speed<br />

c = constant<br />

The power functions Pb =cxn i will be linear functions<br />

when using logarithmic scales.<br />

Therefore, in the Layout Diagrams and Load Diagrams<br />

for diesel engines, logarithmic scales are<br />

used, making simple diagrams with straight lines.<br />

Propeller design point<br />

Normally, estimations of the necessary propeller<br />

power and speed are based on theoretical calculations<br />

for loaded ship, and often experimental tank<br />

tests, both assuming optimum operating conditions,<br />

i.e. a clean hull and good weather. The combination<br />

of speed and power obtained may be called<br />

the ship’s propeller design point (PD), placed on the<br />

light running propeller curve 6. See Fig. 2.01. On the<br />

other hand, some shipyards, and/or propeller manufacturers<br />

sometimes use a propeller design point<br />

(PD’) that incorporates all or part of the so-called<br />

sea margin described below.<br />

Fouled hull<br />

When the ship has sailed for some time, the hull and<br />

propeller become fouled and the hull’s resistance<br />

will increase. Consequently, the ship speed will be<br />

reduced unless the engine delivers more power to<br />

the propeller, i.e. the propeller will be further loaded<br />

and will be heavy running (HR).<br />

As modern vessels with a relatively high service<br />

speed are prepared with very smooth propeller and<br />

hull surfaces, the fouling after sea trial, therefore,<br />

will involve a relatively higher resistance and thereby<br />

a heavier running propeller.<br />

Sea margin at heavy weather<br />

If, at the same time the weather is bad, with head<br />

winds, the ship’s resistance may increase compared<br />

to operating at calm weather conditions.<br />

When determining the necessary engine power, it is<br />

therefore normal practice to add an extra power<br />

margin, the so-called sea margin, see Fig. 2.02<br />

which is traditionally about 15% of the propeller design<br />

(PD) power.<br />

<strong>Engine</strong> layout (heavy propeller)<br />

When determining the necessary engine speed<br />

considering the influence of a heavy running propeller<br />

for operating at large extra ship resistance, it is<br />

recommended - compared to the clean hull and<br />

calm weather propeller curve6-tochoose a heavier<br />

propeller curve 2 for engine layout, and the propeller<br />

402 000 004 198 22 30<br />

2.01<br />

178 05 41-5.3<br />

Line 2 Propulsion curve, fouled hull and heavy weather<br />

(heavy running), recommended for engine layout<br />

Line 6 Propulsion curve, clean hull and calm weather<br />

(light running), for propeller layout<br />

MP Specified <strong>MC</strong>R for propulsion<br />

SP Continuous service rating for propulsion<br />

PD Propeller design point<br />

HR Heavy running<br />

LR Light running<br />

Fig. 2.01: Ship propulsion running points and engine layout

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

curve for clean hull and calm weather in curve 6 will<br />

be said to represent a “light running” (LR) propeller,<br />

see area 6 on Figs. 2.07a and 2.07b.<br />

Compared to the heavy engine layout curve 2 we<br />

recommend to use a light running of 3.0-7.0% for<br />

design of the propeller, with 5% as a good average.<br />

<strong>Engine</strong> margin<br />

178 05 67-7.1<br />

Fig. 2.02: Sea margin based on weather conditions in the<br />

North Atlantic Ocean. Percentage of time at sea where<br />

the service speed can be maintained, related to the extra<br />

power (sea margin) in % of the sea trial power.<br />

Besides the sea margin, a so-called “engine margin”<br />

of some 10% is frequently added. The corresponding<br />

point is called the “specified <strong>MC</strong>R for propulsion”<br />

(MP), and refers to the fact that the power<br />

for point SP is 10% lower than for point MP, see Fig.<br />

2.01. Point MP is identical to the engine’s specified<br />

<strong>MC</strong>R point (M) unless a main engine driven shaft<br />

generator is installed. In such a case, the extra<br />

power demand of the shaft generator must also be<br />

considered.<br />

Note:<br />

Light/heavy running, fouling and sea margin are<br />

overlapping terms. Light/heavy running of the propeller<br />

refers to hull and propeller deterioration and<br />

heavy weather and, – sea margin i.e. extra power to<br />

the propeller, refers to the influence of the wind and<br />

the sea. However, the degree of light running must<br />

be decided upon experience from the actual trade<br />

and hull design.<br />

402 000 004 198 22 30<br />

2.02

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Influence of propeller diameter and pitch on<br />

the optimum propeller speed<br />

In general, the larger the propeller diameter, the<br />

lower is the optimum propeller speed and the kW<br />

required for a certain design draught and ship<br />

speed, see curve D in Fig. 2.03.<br />

The maximum possible propeller diameter depends<br />

on the given design draught of the ship, and the<br />

clearance needed between the propeller and the<br />

aft-body hull and the keel.<br />

The example shown in Fig. 2.03 is an 80,000 dwt<br />

crude oil tanker with a design draught of 12.2 m and<br />

a design speed of 14.5 knots.<br />

When the optimum propeller diameter D is increased<br />

from 6.6 m to 7.2. m, the power demand is<br />

reduced from about 9,290 kW to 8,820 kW, and the<br />

optimum propeller speed is reduced from 120 r/min<br />

to 100 r/min, corresponding to the constant ship<br />

speed coefficient = 28 (see definition of in next<br />

section).<br />

Fig. 2.03: Influence of diameter and pitch on propeller design<br />

Once an optimum propeller diameter of maximum<br />

7.2 m has been chosen, the pitch in this point is<br />

given for the design speed of 14.5 knots, i.e. P/D =<br />

0.70.<br />

However, if the optimum propeller speed of 100<br />

r/min does not suit the preferred / selected main engine<br />

speed, a change of pitch will only cause a relatively<br />

small extra power demand, keeping the same<br />

maximum propeller diameter:<br />

• going from 100 to 110 r/min (P/D = 0.62) requires<br />

8,900 kW i.e. an extra power demand of 80 kW.<br />

• going from 100 to 91 r/min (P/D = 0.81) requires<br />

8,900 kW i.e. an extra power demand of 80 kW.<br />

In both cases the extra power demand is only of<br />

0.9%, and the corresponding 'equal speed curves'<br />

are =+0.1 and =-0.1, respectively, so there is a<br />

certain interval of propeller speeds in which the<br />

'power penalty' is very limited.<br />

402 000 004 198 22 30<br />

2.03<br />

178 47 03-2.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Constant ship speed lines<br />

The constant ship speed lines , are shown at the<br />

very top of Fig. 2.04. These lines indicate the power<br />

required at various propeller speeds to keep the<br />

same ship speed provided that the optimum propeller<br />

diameter with an optimum pitch diameter ratio is<br />

used at any given speed, taking into consideration<br />

the total propulsion efficiency.<br />

Normally, the following relation between necessary<br />

power and propeller speed can be assumed:<br />

P2 =P1 (n2/n1) <br />

where:<br />

P = Propulsion power<br />

n = Propeller speed, and<br />

= the constant ship speed coefficient.<br />

For any combination of power and speed, each<br />

point on lines parallel to the ship speed lines gives<br />

the same ship speed.<br />

When such a constant ship speed line is drawn into<br />

the layout diagram through a specified propulsion<br />

Fig. 2.04: Layout diagram and constant ship speed lines<br />

<strong>MC</strong>R point "MP1", selected in the layout area and<br />

parallel to one of the -lines, another specified propulsion<br />

<strong>MC</strong>R point "MP2" upon this line can be chosen<br />

to give the ship the same speed for the new<br />

combination of engine power and speed.<br />

Fig. 2.04 shows an example of the required power<br />

speed point MP1, through which a constant ship<br />

speed curve = 0.25 is drawn, obtaining point MP2<br />

with a lower engine power and a lower engine speed<br />

but achieving the same ship speed.<br />

Provided the optimum pitch/diameter ratio is used<br />

for a given propeller diameter the following data applies<br />

when changing the propeller diameter:<br />

for general cargo, bulk carriers and tankers<br />

= 0.25 -0.30<br />

and for reefers and container vessels<br />

= 0.15 -0.25<br />

When changing the propeller speed by changing the<br />

pitch diameter ratio, the constant will be different,<br />

see above.<br />

402 000 004 198 22 30<br />

2.04<br />

178 05 66-7.0

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

<strong>Engine</strong> Layout Diagram<br />

The layout procedure has to be carefully considered<br />

because the final layout choice will have a considerable<br />

influence on the operating condition of the main<br />

engine throughout the whole lifetime of the ship. The<br />

factors that should be conisdered are operational flexibility,<br />

fuel consumption, obtainable power, possible<br />

shaft generator application and propulsion efficiency.<br />

An engine’s layout diagram is limited by two constant<br />

mean effective pressure (mep) lines L1-L3 and L2-L4,<br />

and by two constant engine speed lines L1-L2 and<br />

L3-L4, see Fig. 2.04. The L1 point refers to the engine’s<br />

nominal maximum continuous rating.<br />

Please note that the areas of the layout diagrams are<br />

different for the engines types, see Fig. 2.05.<br />

Within the layout area there is full freedom to select the<br />

engine’s specified <strong>MC</strong>R point M which suits the demand<br />

of propeller power and speed for the ship.<br />

On the X-axis the engine speed and on the Y-axis the<br />

engine power are shown in percentage scales. The<br />

scales are logarithmic which means that, in this diagram,<br />

power function curves like propeller curves (3rd<br />

power), constant mean effective pressure curves (1st<br />

power) and constant ship speed curves (0.15 to 0.30<br />

power) are straight lines.<br />

Fig. 2.06 shows, by means of superimposed diagrams<br />

for all engine types, the entire layout area for the<br />

<strong>MC</strong>-programme in a power/speed diagram. As can be<br />

seen, there is a considerable overlap of power/speed<br />

combinations so that for nearly all applications, there<br />

is a wide section of different engines to choose from all<br />

of which meet the individual ship's requirements.<br />

Specified maximum continuous rating, S<strong>MC</strong>R = “M”<br />

Based on the propulsion and engine running points,<br />

as previously found, the layout diagram of a relevant<br />

main engine may be drawn-in. The specified <strong>MC</strong>R<br />

point (M) must be inside the limitation lines of the layout<br />

diagram; if it is not, the propeller speed will have to<br />

be changed or another main engine type must be chosen.<br />

Yet, in special cases point M may be located to<br />

the right of the line L1-L2, see “Optimising Point”.<br />

402 000 004 198 22 30<br />

2.05<br />

Power<br />

Power<br />

Power<br />

Power<br />

L 3<br />

L 4<br />

L 3<br />

L 4<br />

L 3<br />

L 4<br />

L 3<br />

L 4<br />

L 1<br />

L 2<br />

Speed<br />

L 1<br />

L 2<br />

Speed<br />

L 1<br />

L 2<br />

Speed<br />

L 1<br />

L 2<br />

Speed<br />

Fig. 2.05: Layout diagram sizes<br />

Layout diagram of<br />

100 - 64% power and<br />

100 - 75% speed range<br />

valid for the types:<br />

L90<strong>MC</strong>-C S60<strong>MC</strong>-C<br />

K90<strong>MC</strong> S60<strong>MC</strong><br />

S80<strong>MC</strong>-C L60<strong>MC</strong><br />

S80<strong>MC</strong> S50<strong>MC</strong>-C<br />

L80<strong>MC</strong> S50<strong>MC</strong><br />

S70<strong>MC</strong>-C L50<strong>MC</strong><br />

S70<strong>MC</strong> L42<strong>MC</strong><br />

L70<strong>MC</strong><br />

Layout diagram of<br />

100 - 80% power and<br />

100 - 80% speed range<br />

valid for the types:<br />

S90<strong>MC</strong>-C<br />

Layout diagram of<br />

100 - 80% power and<br />

100 - 85% speed range<br />

valid for the types:<br />

K90<strong>MC</strong>-C<br />

K80<strong>MC</strong>-C<br />

S46<strong>MC</strong>-C<br />

S42<strong>MC</strong><br />

S35<strong>MC</strong><br />

L35<strong>MC</strong><br />

S26<strong>MC</strong><br />

Layout diagram of<br />

100 - 80% power and<br />

100 - 90% speed range<br />

valid for the types:<br />

K98<strong>MC</strong><br />

K98<strong>MC</strong>-C<br />

178 13 85-1.4

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 2.06: Layout diagrams of the two-<strong>stroke</strong> engine <strong>MC</strong>-programme as per January 2000<br />

402 000 004 198 22 30<br />

2.06<br />

178 13 80-2.8

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Continuous service rating (S)<br />

The Continuous service rating is the power at which<br />

the engine is normally assumed to operate, and<br />

point S is identical to the service propulsion point<br />

(SP) unless a main engine driven shaft generator is<br />

installed.<br />

Optimising point (O)<br />

The optimising point O is the rating at which the<br />

turbocharger is matched, and at which the engine timing<br />

and compression ratio are adjusted.<br />

On engines with Variable Injection Timing (VIT) fuel<br />

pumps, the optimising point (O) can be different than<br />

the specified <strong>MC</strong>R (M), whereas on engines without<br />

VIT fuel pumps “O” has to coincide with “M”.<br />

The large engine types have VIT fuel pumps as standard,<br />

but on some types these pumps are an option.<br />

Small-bore engines are not fitted with VIT fuel pumps.<br />

Type With VIT Without VIT<br />

K98<strong>MC</strong> Basic<br />

K98<strong>MC</strong>-C Basic<br />

S90<strong>MC</strong>-C Basic<br />

L90<strong>MC</strong>-C Basic<br />

K90<strong>MC</strong> Basic<br />

K90<strong>MC</strong>-C Basic<br />

S80<strong>MC</strong>-C Basic<br />

S80<strong>MC</strong> Basic<br />

L80<strong>MC</strong> Basic<br />

S70<strong>MC</strong>-C Optional Basic<br />

S70<strong>MC</strong> Basic<br />

L70<strong>MC</strong> Basic<br />

S60<strong>MC</strong>-C Optional Basic<br />

S60<strong>MC</strong> Basic<br />

L60<strong>MC</strong> Basic<br />

S50<strong>MC</strong>-C Optional Basic<br />

S50<strong>MC</strong> Basic<br />

S46<strong>MC</strong>-C Basic<br />

S42<strong>MC</strong> Basic<br />

L42<strong>MC</strong> Basic<br />

S35<strong>MC</strong> Basic<br />

L35<strong>MC</strong> Basic<br />

S26<strong>MC</strong> Basic<br />

<strong>Engine</strong>s with VIT<br />

The optimising point O is placed on line 1 of the load<br />

diagram, and the optimised power can be from 85 to<br />

100% of point M's power, when turbocharger(s) and<br />

engine timing are taken into consideration. When<br />

optimising between 93.5% and 100% of point M's<br />

power, 10% overload running will still be possible<br />

(110% of M).<br />

The optimising point O is to be placed inside the layout<br />

diagram. In fact, the specified <strong>MC</strong>R point M can,<br />

in special cases, be placed outside the layout diagram,<br />

but only by exceeding line L1-L2, and of<br />

course, only provided that the optimising point O is<br />

located inside the layout diagram and provided that<br />

the specified <strong>MC</strong>R power is not higher than the L1<br />

power.<br />

<strong>Engine</strong> without VIT<br />

Optimising point (O) = specified <strong>MC</strong>R (M)<br />

On engine types not fitted with VIT fuel pumps,<br />

the specified <strong>MC</strong>R – point M has to coincide with<br />

point O.<br />

402 000 004 198 22 30<br />

2.07

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Load Diagram<br />

Definitions<br />

The load diagram, Figs. 2.07, defines the power and<br />

speed limits for continuous as well as overload operation<br />

of an installed engine having an optimising<br />

point O and a specified <strong>MC</strong>R point M that confirms<br />

the ship’s specification.<br />

Point A is a 100% speed and power reference point<br />

of the load diagram, and is defined as the point on<br />

the propeller curve (line 1), through the optimising<br />

point O, having the specified <strong>MC</strong>R power. Normally,<br />

point M is equal to point A, but in special cases, for<br />

example if a shaft generator is installed, point M may<br />

be placed to the right of point A on line 7.<br />

The service points of the installed engine incorporate<br />

the engine power required for ship propulsion<br />

and shaft generator, if installed.<br />

Limits for continuous operation<br />

The continuous service range is limited by four lines:<br />

Line 3 and line 9:<br />

Line 3 represents the maximum acceptable speed<br />

for continuous operation, i.e. 105% of A.<br />

If, in special cases, A is located to the right of line<br />

L1-L2, the maximum limit, however, is 105% of L1.<br />

During trial conditions the maximum speed may be<br />

extended to 107% of A, see line 9.<br />

The above limits may in general be extended to<br />

105%, and during trial conditions to 107%, of the<br />

nominal L1 speed of the engine, provided the torsional<br />

vibration conditions permit.<br />

The overspeed set-point is 109% of the speed in A,<br />

however, it may be moved to 109% of the nominal<br />

speed in L1, provided that torsional vibration conditions<br />

permit.<br />

Running above 100% of the nominal L1 speed at a<br />

load lower than about 65% specified <strong>MC</strong>R is, however,<br />

to be avoided for extended periods. Only<br />

plants with controllable pitch propellers can reach<br />

this light running area.<br />

Line 4:<br />

Represents the limit at which an ample air supply<br />

is available for combustion and imposes a limitation<br />

on the maximum combination of torque and<br />

speed.<br />

Line 5:<br />

Represents the maximum mean effective pressure<br />

level (mep), which can be accepted for continuous<br />

operation.<br />

Line 7:<br />

Represents the maximum power for continuous<br />

operation.7<br />

Limits for overload operation<br />

The overload service range is limited as follows:<br />

Line 8:<br />

Represents the overload operation limitations.<br />

The area between lines 4, 5, 7 and the heavy dashed<br />

line 8 is available for overload running for limited periods<br />

only (1 hour per 12 hours).<br />

402 000 004 198 22 30<br />

2.08<br />

A 100% reference point<br />

M Specified <strong>MC</strong>R point<br />

O Optimising point<br />

Line 1 Propeller curve through optimising point (i = 3)<br />

(engine layout curve)<br />

Line 2 Propeller curve, fouled hull and heavy weather<br />

– heavy running (i = 3)<br />

Line 3 Speed limit<br />

Line 4 Torque/speed limit (i = 2)<br />

Line 5 Mean effective pressure limit (i = 1)<br />

Line 6 Propeller curve, clean hull and calm weather –<br />

light running (i = 3), for propeller layout<br />

Line 7 Power limit for continuous running (i = 0)<br />

Line 8 Overload limit<br />

Line 9 Speed limit at sea trial<br />

Point M to be located on line 7 (normally in point A)<br />

Regarding “i” in the power functions Pb =cxn i , see<br />

page 2.01

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Fig. 2.07a: <strong>Engine</strong> load diagram for engine with VIT<br />

Fig. 2.07b: <strong>Engine</strong> load diagram for engine without VIT<br />

402 000 004 198 22 30<br />

2.09<br />

178 05 42-7.3<br />

178 39 18-4.1

MAN B&W Diesel A/S <strong>Engine</strong> <strong>Selection</strong> <strong>Guide</strong><br />

Recommendation<br />

Continuous operation without limitations is allowed<br />

only within the area limited by lines 4, 5, 7 and 3 of<br />

the load diagram, except for CP propeller plants<br />

mentioned in the previous section.<br />

The area between lines 4 and 1 is available for operation<br />

in shallow waters, heavy weather and during<br />

acceleration, i.e. for non-steady operation without<br />

any strict time limitation.<br />

After some time in operation, the ship’s hull and propeller<br />

will be fouled, resulting in heavier running of<br />

the propeller, i.e. the propeller curve will move to the<br />

left from line 6 towards line 2, and extra power is required<br />

for propulsion in order to keep the ship’s<br />

speed.<br />

In calm weather conditions, the extent of heavy running<br />

of the propeller will indicate the need for cleaning<br />

the hull and possibly polishing the propeller.<br />

Once the specified <strong>MC</strong>R (and the optimising point)<br />

has been chosen, the capacities of the auxiliary<br />

equipment will be adapted to the specified <strong>MC</strong>R,<br />

and the turbocharger etc. will be matched to the optimised<br />

power, however considering the specified<br />

<strong>MC</strong>R.<br />

If the specified <strong>MC</strong>R (and/or the optimising point) is<br />

to be increased later on, this may involve a change<br />

of the pump and cooler capacities, retiming of the<br />

engine, change of the fuel valve nozzles, adjusting<br />