KESSEL - backwater pumping station Pumpfix® F Standard/Comfort

KESSEL - backwater pumping station Pumpfix® F Standard/Comfort

KESSEL - backwater pumping station Pumpfix® F Standard/Comfort

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

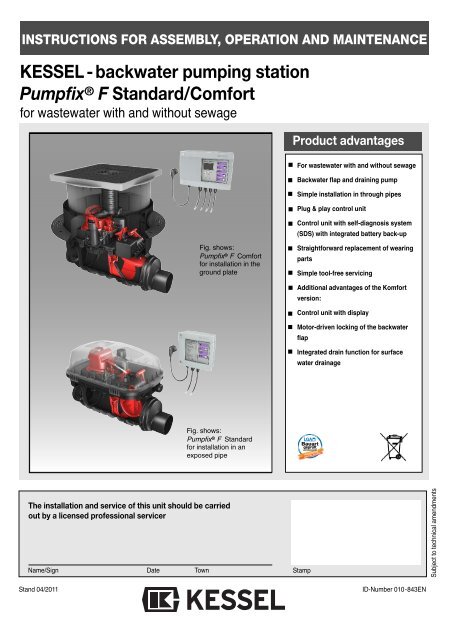

INSTRUCTIONS FOR ASSEMBLY, OPERATION AND MAINTENANCE<br />

<strong>KESSEL</strong> - <strong>backwater</strong> <strong>pumping</strong> <strong>station</strong><br />

Pumpfix ® F <strong>Standard</strong>/<strong>Comfort</strong><br />

for wastewater with and without sewage<br />

The installation and service of this unit should be carried<br />

out by a licensed professional servicer<br />

Name/Sign Date Town<br />

Stand 04/2011<br />

Fig. shows:<br />

Pumpfix ® F <strong>Comfort</strong><br />

for installation in the<br />

ground plate<br />

Fig. shows:<br />

Pumpfix ® F <strong>Standard</strong><br />

for installation in an<br />

exposed pipe<br />

Product advantages<br />

For wastewater with and without sewage<br />

Backwater flap and draining pump<br />

Simple installation in through pipes<br />

Plug & play control unit<br />

Control unit with self-diagnosis system<br />

(SDS) with integrated battery back-up<br />

Straightforward replacement of wearing<br />

parts<br />

Simple tool-free servicing<br />

Additional advantages of the Komfort<br />

version:<br />

Control unit with display<br />

Motor-driven locking of the <strong>backwater</strong><br />

flap<br />

Integrated drain function for surface<br />

water drainage<br />

LGA<br />

Landesgewerbeamt Bayern<br />

Bauart<br />

geprüft geprüft<br />

und und überwacht<br />

überwacht<br />

Stamp<br />

mit Sicherheit<br />

geprüfte Qualität<br />

ID-Number 010-843EN<br />

Subject to technical amendments

Table of contents<br />

1. Safety instructions ........................................................................................................... Page 2<br />

2. General points 2.1 Use ..................................................................................................... Page 3<br />

2.2 Scope of supply.................................................................................. Page 3<br />

2.3 Installation procedure ......................................................................... Page 3<br />

2.4 General instructions about the installation of <strong>backwater</strong> valves ......... Page 3<br />

3. Installation 3.1 Installation in the ground plate............................................................ Page 4<br />

3.2 Recessed installation in the ground plate........................................... Page 4<br />

3.3 Ventilation connection ........................................................................ Page 4<br />

3.4 Installation in an exposed wastewater pipe ........................................ Page 5<br />

3.5 Installation in water load..................................................................... Page 5<br />

3.6 Special features of Pumpfix ® F <strong>Comfort</strong> ............................................. Page 5<br />

3.7 Set-up................................................................................................. Page 5<br />

4. Service and maintenance 4.1 Service ..................................................................................................... Page 6<br />

4.2 Maintenance............................................................................................. Page 6<br />

4.2.1 Mounting the two covers........................................................................... Page 6<br />

4.3 Test ......................................................................................................... Page 6<br />

4.3.1 Test <strong>Standard</strong> ........................................................................................... Page 6<br />

4.3.2 Test <strong>Comfort</strong> ............................................................................................. Page 6<br />

4.4 Pump removal .......................................................................................... Page 7<br />

4.5 Motor installation ...................................................................................... Page 7<br />

4.6 Removing motor ground installation......................................................... Page 7<br />

4.7 How the emergency valve works.............................................................. Page 8<br />

4.7.1 <strong>Standard</strong>................................................................................................... Page 8<br />

4.7.2 <strong>Comfort</strong>..................................................................................................... Page 8<br />

4.8 Servicing the ventilation ........................................................................... Page 8<br />

5. Spare parts 5.1 <strong>Standard</strong>............................................................................................. Page 9<br />

5.2 <strong>Comfort</strong>............................................................................................... Page 10<br />

6. Warranty ......................................................................................... ................. Page 11<br />

7. Commissioning protocol for the installer ........................................................................................................... Page 12<br />

8. Commissioning protocol for the installation company...................................................................................... Page 14<br />

Dear customer,<br />

Before you put your <strong>backwater</strong> <strong>pumping</strong><br />

<strong>station</strong> Pumpfix ® F into operation,<br />

please read through the installation instructions<br />

carefully and follow them.<br />

Check first whether the system has arrived<br />

undamaged. In the event of transport<br />

damage, please follow the instructions in<br />

chapter 6 “Warranty”.<br />

1. Safety instructions:<br />

During installation, operation, maintenance<br />

or repair of the system, the regulations<br />

for the prevention of accidents, the pertinent<br />

DIN and VDE standards and directives,<br />

as well as the directives of the local<br />

power supply industry must be heeded.<br />

Before putting the device into operation,<br />

make sure through professional examination<br />

that the necessary protective features<br />

are available. Grounding, neutral, residual<br />

current-operated protective circuit etc.<br />

must correspond to the requirements of<br />

the local power supply industry.<br />

The system must not be operated in po-<br />

1. Safety instructions<br />

tentially explosive areas.<br />

The system contains electric charges and<br />

controls rotating mechanical system components.<br />

Non-compliance with the operating<br />

instructions may result in considerable<br />

damage to property, personal injuries<br />

or even fatal accidents.<br />

The system must be disconnected<br />

from the mains or made currentless<br />

before any work is carried<br />

out on it.<br />

It must be ensured that the electric cables<br />

as well as all other electrical system<br />

equipment are in a faultless condition. In<br />

case of damage, the system may on no<br />

account be put into operation or must be<br />

stopped immediately.<br />

The system must be inspected and serviced<br />

according to DIN 1986 to maintain its<br />

operational ability.<br />

We recommend that you conclude a servicing<br />

contract with your installation company.<br />

2<br />

No repairs or maintenance work may be<br />

carried out during a <strong>backwater</strong> situation or<br />

if a <strong>backwater</strong> situation is imminent. The<br />

<strong>backwater</strong> flaps and the locking lever always<br />

have to be able to be moved freely.<br />

Note:<br />

No system components may be installed<br />

in protection zone 0 or 1 in accordance<br />

with DIN VDE 0100 701. In the case of<br />

flush-to-floor showers, zone 1 is defined<br />

as with a radius of 1.20 m (projected area<br />

on the floor) around the water intake point.<br />

Deviating local regulations must be taken<br />

into account.<br />

The regulations set out by the directives<br />

VDE 0100, VDE 01107, IEC or by the local<br />

power supply industry must be heeded.<br />

The control unit must not be installed in<br />

rooms where there is an explosion hazard.<br />

For the operation of this system,<br />

these instructions and instructions no.<br />

010-846 must be used together!

2.1 Use<br />

The <strong>KESSEL</strong> <strong>backwater</strong> <strong>pumping</strong> <strong>station</strong><br />

Pumpfix ® F has been designed for through<br />

wastewater pipes that have soiled water<br />

pipes as well as toilets and urinals connected<br />

to them. This guarantees the safe draining<br />

of draining spots below the <strong>backwater</strong><br />

level even during <strong>backwater</strong>. The pump only<br />

works during <strong>backwater</strong> and pumps the soiled<br />

water into the sewage channel against<br />

the <strong>backwater</strong>. During <strong>backwater</strong>-free operation,<br />

the soiled water is discharged into<br />

the sewage channel through the natural<br />

gradient.<br />

Pumpfix ® does not provide protection<br />

against rats! If there is a rat hazard, the system<br />

must be protected from damage onsite.<br />

A rat protection flap is available as an option<br />

and prevents damage caused by gnawing<br />

to a large extent (<strong>Standard</strong> only).<br />

Important:<br />

Pre-condition for trouble-free operation is<br />

• Sufficient gradient in the draining pipes<br />

(note: there is a gradient of 9 mm between<br />

feed and drain with <strong>Pumpfix®</strong> F)<br />

• A high share oSufficient gradient in the<br />

draining pipes (note: there is a gradient<br />

of 9 mm between feed and drain with<br />

<strong>Pumpfix®</strong> F)<br />

• A high share of water in the wastewater<br />

to optimise the self-cleaning effect<br />

• Correct routing and ventilation of the<br />

feed pipe in accordance with DIN EN<br />

12056 / DIN 1986-100<br />

• Use with greasy wastewater only possible<br />

with increased maintenance and<br />

cleaning efforts<br />

• Rain surfaces up to max. 20 m 2<br />

Installation of a <strong>backwater</strong> valve in the right place<br />

Backwater protection<br />

2. General<br />

2.2 Scope of supply<br />

The scope of supply of the <strong>KESSEL</strong> <strong>backwater</strong><br />

<strong>pumping</strong> <strong>station</strong> Pumpfix ® F is<br />

made up of the drain body with pump and<br />

<strong>backwater</strong> valve and the electric packages.<br />

The electric packages are made up of:<br />

<strong>Standard</strong><br />

1. The optical probe<br />

2. A control unit (mains connection 230 V,<br />

50 Hz, protective rating IP 54) with battery<br />

back-up (2 x 9V) for alarm message<br />

in the event of a power failure.<br />

3. An installation and operating manual<br />

<strong>Comfort</strong><br />

1. Two optical probes and the drive motor<br />

2. One control unit with display (mains<br />

connection 230 V, 50 Hz, protective rating<br />

IP54) with battery back-up (2 x 9V) for<br />

alarm message in the event of a power<br />

supply.<br />

3. An installation and operating manual<br />

2.3 Installation procedure<br />

During the construction phase only the drain<br />

body is installed and connected in accordance<br />

with chapter 3. Usually, the power<br />

connection (chapter 4) and subsequent initial<br />

operation (chapter 5) cannot be carried<br />

out directly. Please connect the electric system<br />

components (pump, probes, motor<br />

and control unit, depending on the variant)<br />

when you put the <strong>KESSEL</strong> <strong>backwater</strong> <strong>pumping</strong><br />

<strong>station</strong> <strong>Pumpfix®</strong> F into operation. Until<br />

this point, the enclosed electric package<br />

and the control unit must be kept stored in a<br />

clean and dry place. Only remove the plug<br />

end plates when the system is put into operation.<br />

Care must be taken that the system is always<br />

sealed with an upper cover section<br />

and cover or protective hood when set up as<br />

Right!<br />

Backwater<br />

level<br />

3<br />

Backwater protection<br />

a free-standing device in order to prevent<br />

soiling of the system.<br />

Caution: The pump is secured by a transportation<br />

safety tape that has to be removed<br />

before initial operation.<br />

2.4 General instructions about the installation<br />

of <strong>backwater</strong> valves<br />

According to DIN EN 12056 <strong>backwater</strong> valves<br />

may not be used to protect all the draining<br />

points of a building - including those<br />

above the <strong>backwater</strong> level (street level) - because<br />

if the <strong>backwater</strong> valve is closed, the<br />

wastewater from above can no longer be<br />

drained into the sewage pipe but will - according<br />

to the principle of communicating<br />

pipes - escape from the drainage points furthest<br />

below the <strong>backwater</strong> level first (usually<br />

basement rooms) and thus flood the basement.<br />

Only draining points below the <strong>backwater</strong><br />

level may be protected against <strong>backwater</strong>.<br />

All draining points above the <strong>backwater</strong><br />

level must be discharged into the sewage<br />

pipe with free gradient past the <strong>backwater</strong><br />

valve.<br />

Consequence: separate pipe routing.<br />

Domestic wastewater above the <strong>backwater</strong><br />

level can thus rise up to a maximum of street<br />

level inside the downpipe without flooding<br />

the basement.<br />

Rainwater must never be discharged via<br />

<strong>backwater</strong> valves.<br />

Installation of a <strong>backwater</strong> valve in the wrong place<br />

Wrong!<br />

Backwater<br />

level

Please note:<br />

DIN EN 12056 must always be heeded when<br />

routing the base pipes. Downpipes must always<br />

be introduced downstream from the<br />

<strong>Pumpfix®</strong> F (about 1m). In addition, a stilling<br />

section must be observed upstream and downstream<br />

of the FKA (at least 1 m). During installation<br />

of the <strong>backwater</strong> valve, care must be<br />

taken that there is a sufficient gap to the wall<br />

for maintenance work to be carried out. The<br />

KG pipe must not be connected directly to the<br />

drain body but only to the muff.<br />

Caution: During installation pay attention<br />

to the direction of flow arrows on the product.<br />

3.1 Kessel <strong>backwater</strong> <strong>pumping</strong> <strong>station</strong><br />

Pumpfix ® F for installation in the<br />

ground plate<br />

DThe drain body of the <strong>KESSEL</strong>-<strong>Pumpfix®</strong> F<br />

must be aligned horizontally (see Fig. 1).<br />

For connection of the electric cables of probe<br />

and pump, a cable conduit (at least DN 50,<br />

Kessel recommends 2 x 45° bends) must be<br />

provided. A second probe cable and motor<br />

connection cable must be connected for the<br />

Komfort variant. For this, a cable conduit (at<br />

least DN 70, Kessel recommends 2 x 45°<br />

bends) must be planned. To do this, lay the<br />

cable conduit to at least finished flooring height<br />

(see Fig. 2) and insert in the cable duct in the<br />

adapter of the <strong>KESSEL</strong> <strong>Pumpfix®</strong> F (cable<br />

conduit should protrude about 2 cm into the interior<br />

- tightness (Fig. 5). Changes of direction<br />

must be laid with bends of max. 45°. To guarantee<br />

proper aerating and venting of the pump<br />

chamber, the cable conduit must not be sealed<br />

airtight. Insert the enclosed profile lip seal into<br />

the adapter groove and grease this. Then<br />

mount the upper cover section (see Fig. 3).<br />

Thanks to the telescopic design of the upper<br />

cover section, the <strong>KESSEL</strong>-<strong>Pumpfix®</strong> F can be<br />

adapted exactly to the prevailing installation<br />

depth. Ground slopes of up to 5° can be compensated.<br />

The upper cover section can also be<br />

turned to align the cover to the tile pattern, for<br />

example (see Fig. 4). The seal must be<br />

checked for a good fit after adjustment.<br />

CAUTION:<br />

The upper cover section must be shortened<br />

to the necessary size to achieve minimum<br />

installation depth. If necessary,<br />

recesses must be cut out of the upper<br />

cover section near the cable conduit and<br />

the ventilation pipe. Maximum groundwater<br />

resistance is 2 m. Following final<br />

alignment of the upper cover section, a<br />

recess may have to be introduced near<br />

the cable duct to enable the cable to be<br />

pulled out again during later inspections<br />

(see Fig. 5).<br />

The lip seal must be fitted in the cover plate.<br />

Care must be taken that the sealing lip and<br />

3. Installation<br />

centring lug are facing upwards during installation.<br />

The centring lug must be placed in the<br />

recess (see Fig. 6).<br />

During installation, make sure that the function<br />

of units in the chamber is not impaired by construction<br />

material.<br />

Installation of covers with a choice of finishes<br />

(tile height max. 15 mm).<br />

With the covers with a choice of finishes, tiles<br />

or natural stone can be inserted in the cover on<br />

site, so that they can be matched to the roomʼs<br />

flooring. Products e.g. from PCI, Schomburg,<br />

Deitermann are suitable for tile laying. To<br />

achieve straightforward processing and adhesion,<br />

we recommend the following procedure:<br />

Tile laying:<br />

a) aPrime the cover plate e.g. with PCI primer<br />

303. Following the respective flash-off time,<br />

lay the tiles with silicone. This type of laying<br />

is particularly suitable for thinner tiles since<br />

the base can be filled up to the required<br />

height.<br />

b) Laying the tiles e.g. using PCI Silcoferm S<br />

(self-adhesive silicone). This allows a thin<br />

adhesive bed to be used, particularly good<br />

for thicker tiles.<br />

Laying natural stone:<br />

(marble, granite, agglo-marble):<br />

a) Prime the cover plate e.g. with PCI primer<br />

303. Lay the natural stone panels using e.g.<br />

PCI-Carralit..<br />

b) Laying the natural stone panels using e.g.<br />

PCI-Carraferm (special silicone for natural<br />

stone). Areas of application analogue to<br />

“Laying tiles”.<br />

3.2 Recessed installation in the ground<br />

plate<br />

(order no. 83071). Chapter 3.4 must be heeded<br />

for installation in water load.<br />

Depending on the installation depth, one or<br />

max. two extension pieces can be used between<br />

the upper cover section and the adapter.<br />

The respective seals must be greased accordingly.<br />

Please note that with recessed installation you<br />

still have to be able to reach down to the drain<br />

body for maintenance purposes.<br />

3.3. Ventilation connection<br />

<strong>Pumpfix®</strong> F is fitted as standard with a ventilation<br />

valve with activated carbon filter. Alternatively,<br />

ventilation according<br />

to standard<br />

can be connected. For<br />

this, the ventilation<br />

valve can be removed<br />

and connected directly<br />

to a ventilation pipe<br />

(to the roof).<br />

4<br />

Fig. 1<br />

fig. 2<br />

Fig. 3<br />

Fig. 4<br />

fig. 5<br />

Fig. 6

3.4 Installation in an exposed wastewater<br />

pipe<br />

The version for free-standing set-up is delivered<br />

with a protective hood to prevent damage to<br />

the components following commissioning. Fig.<br />

7 shows the cable ducts – 1 or 2 (depending on<br />

the variant).<br />

3.5 Installation in water load<br />

(Seal set art. no. 83023<br />

Fig. 7<br />

If the valve is to be installed in water load,<br />

the flange serves as the necessary sealing<br />

level for a white or black tub (see Figure).<br />

For this purpose, seal sheeting is clamped<br />

between the plastic counterflange and the<br />

compression seal flange integrated on the<br />

drain body, and screwed together using the<br />

enclosed screws.<br />

The sheeting used on site can be used as<br />

seal sheeting. For installation in a waterproof<br />

white tub, <strong>KESSEL</strong> also has matching<br />

seal sheeting available made of natural rubber<br />

NK/SBR, where the bore holes for the<br />

screws have already been cut out (see Fig.<br />

8).<br />

If it is necessary to perforate the waterproof<br />

concrete tub to connect feed pipes, cable<br />

conduits etc., these holes must also be set<br />

up waterproof. Maximum groundwater resistance<br />

is 2 m.<br />

Installation example “black tub”<br />

BWS*<br />

4<br />

Tiles Fliesen<br />

Screed Estrich<br />

Insulation Dämmung<br />

Concrete Betonboden floor<br />

Protective Schutzbeton concrete<br />

Sealing Abdichtung<br />

Underfloor Unterbeton<br />

➀ <strong>KESSEL</strong>-<strong>Pumpfix®</strong> F, Staufix® FKA, Staufix® SWA, Controlfix<br />

➁ Compression seal flange with seal set art. no. 83023<br />

➂ Extension art. no. 83071<br />

➃ Adapter DN 100 with compression seal flange made of stainless<br />

steel art. no. 27198<br />

2<br />

3<br />

1<br />

3. Einbau<br />

Installation with extension (order no.<br />

83071).<br />

Use of the extension allows the flange<br />

height to be individually adjusted. The<br />

attachment must be shortened to the required<br />

height if necessary.<br />

3.6 Special features of Pumpfix ® F<br />

<strong>Comfort</strong><br />

Pumpfix F Komfort has an integrated draining<br />

function for surface water drainage.<br />

3.7 Set-up<br />

Connection of the draining function to the<br />

feed cover is via the enclosed draining<br />

connection. Insert the draining connection<br />

into the prescribed opening and lock using<br />

the one-handed quick-action closure.<br />

Depending on installation depth (installation<br />

depth of the upper cover section), the<br />

draining connection must be shortened to<br />

the respective length (see Fig. 9) or extended<br />

using HT-pipe DN 70 if recessed installation<br />

using extension (art. no. 83071) is<br />

used.<br />

5<br />

BWS *<br />

Fig 9<br />

4<br />

5<br />

Pumpfix<br />

S<br />

® F <strong>Comfort</strong><br />

Installation example “white tub”<br />

Seal seat (83023)<br />

• Counterflange • Sealing sheet<br />

Fig. 8<br />

Pressdichtungsflansch<br />

Tiles Fliesen<br />

Screed Estrich<br />

Insulation Dämmung<br />

Concrete Betonboden floor<br />

➄ Elastomer sealing sheet art. no. 27159<br />

➅ Upper cover section with plastic cover plate<br />

➆ Control unit<br />

➇ Locking lever<br />

2<br />

➇<br />

➅<br />

1<br />

➆<br />

WU-Beton

4.1 Service<br />

The system must be checked once every<br />

month by the operator through observation<br />

of the switching routine for operational<br />

ability and leaks.<br />

• Close emergency valve or with Komfort:<br />

press test key to carry out functional test<br />

on <strong>backwater</strong> valve -> valve closes<br />

• Allow water to flow in<br />

• Wait until level-LED + pump trigger.<br />

• Switch off water feed<br />

• Switch off level-LED and wait for pump<br />

• Open hand lever (vertical position OPEN)<br />

-> <strong>Standard</strong><br />

Komfort: Please note that the <strong>backwater</strong><br />

valve must be open after the inspection<br />

has been completed.<br />

The pump should be checked at regular intervals.<br />

If operational noises increase,<br />

<strong>pumping</strong> capacity decreases or there are<br />

vibrations in the pipeline system, the pump<br />

housing and impeller must be checked for<br />

any stubborn soiling or wear.<br />

4.2 Maintenance (at least every six<br />

months)<br />

CAUTION: Disconnect the unit from the<br />

mains during all servicing work! Heed<br />

safety instructions! No warranty will be<br />

granted in the event of insufficient<br />

maintenance! All the servicing and<br />

maintenance work described below<br />

may only be carried out by authorised<br />

qualified personnel. Repairs may only<br />

be carried out by the manufacturer.<br />

DIN 1986, part 3, must be heeded during<br />

maintenance work on systems. Maintenance<br />

work must be carried out at least every<br />

six months by authorised qualified staff.<br />

The following tasks have to be carried out:<br />

• Visual inspection of the complete system<br />

• Thorough cleaning of the complete system<br />

and the pump<br />

• Check on the complete system and pump<br />

housing for external damage and visible<br />

wear<br />

• Check on the pump for free movement,<br />

wear and deposits<br />

• Check the connection cables for mechanical<br />

damage and wear<br />

• Check the seal connections for leaks and<br />

any recognisable wear<br />

• Insulation test on the pump motor<br />

• Check the control unit for damage and<br />

soiling<br />

• Check and clean the ventilation valve<br />

• Clean the optical probe<br />

4. Service and maintenance<br />

We recommend these jobs after longer periods<br />

of standstill or intermediate storage, too,<br />

as well as after longer or frequent occurrences<br />

of <strong>backwater</strong>. If problems should occur<br />

that cannot be eliminated, please contact<br />

the specialist company who carried out the<br />

installation (see stamp on cover sheet) if in<br />

doubt.<br />

4.2.1 Mounting the two covers (see Fig.<br />

12, 13, 14)<br />

Insert the covers on one side, push the other<br />

side down and lock in place using the locking<br />

levers. During installation of the overflow<br />

cover the red flap lever or the motor flap position<br />

must always be “CLOSED”<br />

4.3 Test<br />

<strong>Standard</strong> <strong>Comfort</strong><br />

a) Pull the insertable part out<br />

b) Clean all the parts<br />

c) Check the seals<br />

d) Apply lubricant (e.g. fittings grease)<br />

to the outside of the seals of the insertable<br />

parts as well as the guide<br />

parts of the flap valves<br />

6<br />

e) Insert the insertable part exactly<br />

f) Make sure the attachment clips are in<br />

place properly!<br />

g) Heed cover installation 4.2.1<br />

h) Carry out functional test in accordance<br />

with instruction manual 010-846.<br />

Abb. 12<br />

4.3.1 Test <strong>Standard</strong><br />

1. Hold the pump probe into the water "On" level Level-LED lit<br />

Pump starts Pump-LED lit<br />

4.3.2 Test <strong>Comfort</strong><br />

1. Hold the motor probe into the water Flap closes Backwater-LED flashes<br />

Flap-LED flashes<br />

Flap closed Backwater-LED flashes<br />

Flap-LED lit<br />

2. Hold the pump probe into the water Pump starts Pump-LED lit

5.1 <strong>Standard</strong><br />

Pumpfix ® F for installation in an exposed wastewater pipe<br />

All spare parts can be purchased from a specialist company.<br />

Designation Art. no.<br />

➀ Pumpfix ® F-control unit <strong>Standard</strong> IP 54 28073<br />

a) Additional board for potential-free contact 80072<br />

b) Remove signal generator 20 m 20162<br />

c) Battery 9V (2 units required) 197-081<br />

➁ Optical probe IP 68 (5 m, inc. adapters) 80888<br />

➂ Cover pump feed side (without outlet function) 28052<br />

➃ Pumpfix ® F-cover <strong>Standard</strong> outlet side 28053<br />

➄ Pumpfix ® F-pump IP 68 (5m, inc. plug) 28351<br />

➅ Ventilation complete 28060<br />

a) Activated carbon filter 28061<br />

➆ Mechanical flap 80033<br />

➇ Insertion part for mechanical flap 80034<br />

➈ Hood 80031<br />

Transition piece 83032<br />

Seal set II 70319<br />

Pumpfix ® F for installation in the ground plate<br />

All spare parts can be purchased from a specialist company.<br />

Designation Art. no.<br />

➀ Pumpfix ® F-control unit <strong>Standard</strong> IP 54 28073<br />

a) Additional board for potential-free contact 80072<br />

b) Remove signal generator 20 m 20162<br />

c) Battery 9V (2 units required) 197-081<br />

➁ Optical probe IP 68 (5 m, inc. adapters) 80888<br />

➂ Cover pump feed side (without outlet function) 28052<br />

➃ Pumpfix ® F-cover <strong>Standard</strong> outlet side 28053<br />

➄ Pumpfix ® F-pump IP 68 (5m, inc. plug) 28351<br />

➅ Ventilation complete 28060<br />

6a) Activated carbon filter 28061<br />

➆ Mechanical flap 80033<br />

➇ Insertion part for mechanical flap 80034<br />

Seal set II 70319<br />

5. Spare parts<br />

9<br />

➂<br />

<br />

<br />

<br />

➄<br />

<br />

➁<br />

<br />

<br />

a<br />

➆<br />

<br />

a<br />

<br />

➀<br />

a,b,c<br />

➀<br />

a,b,c

5.2 <strong>Comfort</strong><br />

Pumpfix ® F for installation in an exposed wastewater pipe<br />

All spare parts can be purchased from a specialist company.<br />

Designation Art. no.<br />

➀ Pumpfix ® F-control unit Komfort IP 54 28071<br />

a) Additional board for potential-free contact 80072<br />

b) Remove signal generator 20 m 20162<br />

c) Battery 9V (2 units required) 197-081<br />

➁ Optical probe IP 68 (5 m, inc. adapters) 80888<br />

➂ Cover pump feed side (without outlet function) 28052<br />

➃ Pumpfix ® F-cover Komfort outlet side 28056<br />

➄ Pumpfix ® F-pump IP 68 (5m, inc. plug) 28351<br />

➅ Ventilation complete 28060<br />

a) Activated carbon filter 28061<br />

➆ Motor-driven flap 80038<br />

➇ Insertion part for motor-driven flap 80039<br />

➈ Hood 83031<br />

Transition piece 83032<br />

Drive motor IP 68 (5m cable) 80076<br />

Seal set II 70319<br />

Pumpfix ® F for installation in the ground plate<br />

All spare parts can be purchased from a specialist company.<br />

Designation Art. no.<br />

➀ Pumpfix ® F-control unit Komfort IP 54 28071<br />

a) Additional board for potential-free contact 80072<br />

b) Remove signal generator 20 m 20162<br />

c) Battery 9V (2 units required) 197-081<br />

➁ Optical probe IP 68 (5 m, inc. adapters) 80888<br />

➂ Cover pump feed side (with outlet function) 28054<br />

➃ Pumpfix ® F-cover Komfort outlet side 28056<br />

➄ Pumpfix ® F-pump IP 68 (5m, inc. plug) 28351<br />

➅ Ventilation complete 28060<br />

6a) Activated carbon filter 28061<br />

➆ Motor-driven flap 80038<br />

➇ Insertion part for motor-driven flap 80039<br />

Drive motor IP 68 (5m cable) 80076<br />

Seal set II 70319<br />

5. Spare parts<br />

10<br />

➂<br />

<br />

<br />

<br />

<br />

➁<br />

➄<br />

<br />

<br />

<br />

<br />

➁<br />

a<br />

<br />

➆<br />

<br />

a<br />

<br />

➀<br />

a,b,c<br />

➀<br />

a,b,c

1. In the case that a <strong>KESSEL</strong> product is defective,<br />

<strong>KESSEL</strong> has the option of repairing<br />

or replacing the product. If the product<br />

remains defective after the second<br />

attempt to repair or replace the product or<br />

it is economically unfeasible to repair or<br />

replace the product, the customer has<br />

the right to cancel the order / contract or<br />

reduce payment accordingly. <strong>KESSEL</strong><br />

must be notified immediately in writing of<br />

defects in a product. In the case that the<br />

defect is not visible or difficult to detect,<br />

<strong>KESSEL</strong> must be notified immediately in<br />

writing of the defect as soon as it is discovered.<br />

If the product is repaired or replaced,<br />

the newly repaired or replaced<br />

product shall receive a new warranty<br />

identical to that which the original (defective)<br />

product was granted. The term defective<br />

product refers only to the product<br />

6. Warranty<br />

or part needing repair or replacement<br />

and not necessarily to the entire product<br />

or unit. <strong>KESSEL</strong> products are warranted<br />

for a period of 24 month. This warranty<br />

period begins on the day the product is<br />

shipped form <strong>KESSEL</strong> to its customer.<br />

The warranty only applies to newly manufactured<br />

products. Additional information<br />

can be found in section 377 of the<br />

HGB.<br />

In addition to the standard warranty,<br />

<strong>KESSEL</strong> offers an additional 20 year warranty<br />

on the polymer bodies of class I / II<br />

fuel separators, grease separators, inspection<br />

chambers, wastewater treatment<br />

systems and rainwater storage<br />

tanks. This additional warranty applies to<br />

the watertightness, usability and structural<br />

soundness of the product.<br />

11<br />

A requirement of this additional warranty<br />

is that the product is properly installed<br />

and operated in accordance with the valid<br />

installation and user's manual as well as<br />

the corresponding norms / regulations.<br />

2. Wear and tear on a product will not be<br />

considered a defect. Problems with products<br />

resulting from improper installation,<br />

handling or maintenance will also be considered<br />

a defect.<br />

Note: Only the manufacturer may open<br />

sealed components or screw connections.<br />

Otherwise, the warranty may become<br />

null and void<br />

01.06.2010

7. Commissioning Protocol for installer<br />

Separator Type: __________________________________________________________<br />

Day / Hour __________________________________________________________<br />

Project description /Building services supervisor __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

Builder __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

Planner __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

Contracted plumbing company __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

<strong>KESSEL</strong>-Commissions no.:<br />

System operator /owner __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

User __________________________________________________________<br />

Address __________________________________________________________<br />

Telephone / Fax __________________________________________________________<br />

Person of delivery __________________________________________________________<br />

Other remarks __________________________________________________________<br />

The system operator, and those responsible, were present during the commissioning of this system.<br />

____________________________ ____________________________ ____________________________<br />

Place and date Signature owner Signature user<br />

12

Notice<br />

13

8. Commissioning Protocol for installation company<br />

Handover certificate (copy for the company carrying out the installation)<br />

❏ The initial operation and instruction was carried out in the presence of the person authorised to perform the acceptance<br />

and the system operator.<br />

❏ The system operator/person authorised to perform the acceptance was informed about the obligation to service<br />

the product according to the enclosed operating instructions.<br />

❏ Initial operation and instruction were not carried out.<br />

The client/ person responsible for initial operation was handed the following components and/or product components<br />

Initial operation and instruction is being carried out by (company, address, contact, phone)<br />

The exact coordination of the dates for initial operation/instruction is being carried out by the system operator and person<br />

responsible for initial operation.<br />

Place, date Signature of person Signature of system operator Signature of the company<br />

authorised to perform acceptance carrying out the installation work<br />

14

❑ Backwater protection<br />

❑ Lifting Stations and pumps<br />

❑ Drains and shower channels<br />

❑ Separators<br />

-Grease Separators<br />

-Oil-/Fuel-/Coalescence<br />

Separators<br />

-Starch Separators<br />

-SedimentSeparators<br />

❑ Septic Systems<br />

❑ Inspection Chambers<br />

❑ Rainwater Management<br />

Systems