foi_2009_0054_response_9/2/2009_sec 4 - Hanford Site

foi_2009_0054_response_9/2/2009_sec 4 - Hanford Site

foi_2009_0054_response_9/2/2009_sec 4 - Hanford Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

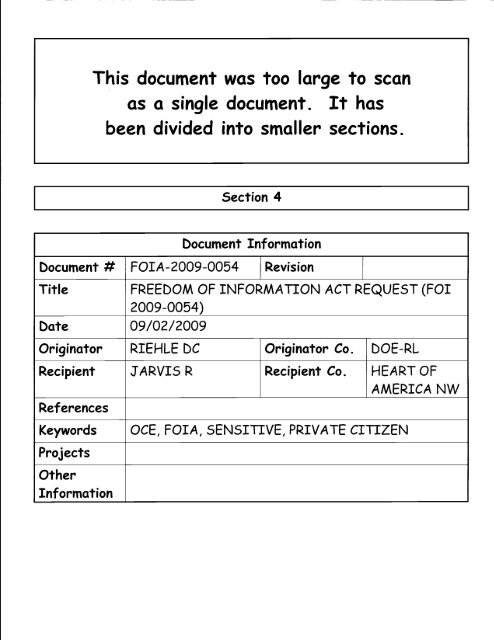

This document was too large to scan<br />

as a single document. It has<br />

been divided into smaller <strong>sec</strong>tions.<br />

Section 4]<br />

Document Inf ormation<br />

Document # FOIA-<strong>2009</strong>-<strong>0054</strong> Revision<br />

Title<br />

FREEDOM OF INFORMATION ACT REQUEST (FOI<br />

<strong>2009</strong>-<strong>0054</strong>)<br />

Date 09/02/<strong>2009</strong><br />

Originator RIEHLE bC Originator Co. bOE-RL<br />

Recipient JAR VI5 R Recipient Co. HEART OF<br />

References<br />

Keywords<br />

Projects<br />

__________AMERICA<br />

OCE, FOTA, SENSITIVE, PRIVATE CITIZEN<br />

NW<br />

Other<br />

Information___________________________

WHC-SD-W025-RPT-001, Rev. 0<br />

W-025-017<br />

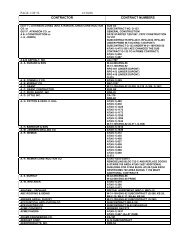

ECN TDescription o.<br />

of Change<br />

If the installer elects to weld geomembrane seams in ambient temperatures<br />

below 400 F or above 1040 F, the installer must certify that such seams will be<br />

comparable to seams welded in ambient temperatures between 400 F and 104'<br />

F, and additional coupons (from the ends of such seamns) shall be tested to<br />

verify the quality of the welds.<br />

SDR 13.5 HDPE pipe or SDR 15.5 HDPE pipe may be used for the Collector<br />

Well.<br />

End caps shall be provided for the cleaout access pipes.<br />

"Valve" <strong>sec</strong>tion of specifications shall be replaced with new <strong>sec</strong>tion which<br />

includes specifications for a hose bib, and ball valves. Adds six valves to the<br />

valve schedule.<br />

Supply additional butterfly valves to allow recirculation of leachate.<br />

Supply two turbine metersto 'allow determination of the quantity of discharge<br />

from each the primfary and' <strong>sec</strong>ondary surmps.<br />

__________Mount a high level limit switch on the liquid level gauge.<br />

W-025-01 8<br />

W-025-019<br />

W-025-020<br />

W-025-021<br />

W-025-022<br />

Changed Design D~rawings to incorporate valves, meters, piping, and switch<br />

indicated by ECN #17 (W-025-017).<br />

Modified Acceptance Test Procedure. Major changes included testing spare<br />

pumps at the ground surface, testing flowmeters, and testing control panel<br />

heaters.<br />

Heat trace cable can be either 120 volt or 240 volt. A 30-Amp, two pole circuit<br />

breaker shall be used for 240 volt heat trace cable.<br />

Provide control panel heaters to maintain temperature within operating range of'<br />

components during cold weather.<br />

Lower subgrade elevations of truck staging area and site entrance road to allow<br />

installation of eight inches of top course and four inches of asphalt.<br />

Provide electric pump, accessories, and connections to allow removal of liquid<br />

from containment basin under leachate tankc.<br />

Provide stairway and railing to enable access to containment basin.<br />

933-1354 6

WHC-SD-W025-RPT-01, Rev. 0<br />

ECN No.<br />

W-0,25-007<br />

JDescription of Change<br />

Change Instrumentation/Electrical Acceptance Test Procedure:<br />

Circuit breaker for pump WSP I to be located on Panel A.<br />

Edit WP51 to W5P1.<br />

W-025-008<br />

W-025-009<br />

W-025-010<br />

Measure phase currents for pumps prior to testing. Verify that overload<br />

devices are sized correctly.<br />

Editorial changes to Design Drawings and title blocks of Drawings.<br />

Editorial changes to CQA Plan tables.<br />

Only two friction angle tests are required for each of the following interfaces:<br />

Textured geomeinbrane/soil liner<br />

Textured geomembrane/geocomposite<br />

__________<br />

W-025-01 1<br />

W-025-012<br />

Geocomposite/operations layer<br />

Clarified CQA Plan such that only two friction angle tests are required for the<br />

interfaces indicated in ECN #10 (W-025-010).<br />

Move site access road northward approximately 10 ft to avoid an existing<br />

power pole.<br />

W-025-013 Nominal Transmissivity of geonet shall be a minimum of 0.001 ma/<strong>sec</strong> (4.8<br />

gallrnfr) at 10,000 psf normal load, and the Mass/Unit Area shall be a<br />

minimum of 22 ozlyd'.<br />

___________discharge<br />

W-025-014<br />

_________Trap<br />

W-025-015<br />

W-025-016<br />

Type A geotextile shall have Mass/Unit Area of 7.0 oz/yd' or greater, and<br />

Permittivity shall be 1.2 <strong>sec</strong>' or greater.<br />

1.5-in. diameter, SDR 11, HDPE pipe is acceptable for submersible pump<br />

piping.<br />

Type B geotextile shall have a minimum thickness of 170 mils, a minimum<br />

Tear Strength of 135 Ibs, and a minimum permittivity of 0.40 <strong>sec</strong>'.<br />

The first lift of admix material may be placed in a 12-inch thick loose lift.<br />

The minimum density of the resin used to manufacture the geotnembrane<br />

material shall be 0.930.<br />

933-1354 5

WHC-SD-W025-R'r-001, Rev. 0<br />

* Construction Quality Assurance Plan for Project W-025, Radioactive Mixed Waste<br />

(M) Land Disposal Facility-- Non-Drag-Off, Revision_3, prepared for the U.S.<br />

Department of Energy - Richland Operations Office, Contract No. DE-ACO6-<br />

89R.LI1615, by Golder Associates Inc., dated May 21, 1993.<br />

* Qualit-y.Assurance Prozm Plan for Project W-025. Radioactive Mixed Waste (RMVT)<br />

Land Disposal Facility - Non-Drag-Off. Revision 3 prepared for the U.S. Department<br />

of Energy - Richland Operations Office, Contract No. DE-AC06-89RL1 1615, by<br />

Golder Associates Inc., dated April, 1991.<br />

Construction issues were discussed and clarified in a preconstruction meeting which was held at<br />

the offices of Kaiser Engineers <strong>Hanford</strong> on August 25, 1993. Minutes of the meeting, recorded by<br />

Kaiser Engineers <strong>Hanford</strong>, are included in Appendix C-1.<br />

A <strong>sec</strong>ond preconstruction meeting, with GCS and GeoPacific personnel in attendance, was held<br />

onsite on November 17, 1993, to discuss and clarify geosynthetics installation issues. Minutes of the<br />

meeting, recorded by GCS, are included in Appendix C-2.<br />

During construction of the landfill, seveial Issues regarding design and construction were<br />

encountered. These issues were discussed with the Design Engineer of record, Golder Associates Inc.<br />

(GAI), and resolutions to the issues were determined. An -Engineering Change Notice (ECN) was<br />

prepared by the Design Engineer for each construction issue which warranted a design or specification<br />

change. These documents ame included in Appendix C-3.<br />

Engineering Change Notices (ECN) W-025-006 through W-025-026, W-025-028, W-025-029,<br />

W-025-031, and W-025-032 arm summnarized in Table 2. ECNs W-025-001 through W-025-005 were<br />

completed prior to the bidding date for this project, were incorporated to the specification package and<br />

Design Drawings prior to the bid date and are not included in Table 2. ECNs W-025-027 and W-025-<br />

030 involved the <strong>sec</strong>ond landfill, Project W-02SA, and are not included in Table 2.<br />

Table 2. Engineering Change Notice Summary.<br />

ECN NO. IDescription of Change<br />

W-025-006<br />

Submit qualifications of organization and personnel who will serve as<br />

geosynthetics installer.<br />

Add <strong>sec</strong>tion to specifications for Dry Type Transformers.<br />

Pole mounted transformers - change from 75 KV BEL to 95 KV BEL.<br />

Open fuse cutouts shall be extra heavy duty, 100 Amp continuous, 5600 Amp<br />

interrupting duty or better. Cutouts shall be fused with ir fuses.<br />

__________Grounding shall be performed in accordance with NE6SC rules 96 & 97.<br />

933-1354 4

WHC-SD-W025-RPT-00l. Rev. 0<br />

Table 1. Lining and Leachate Collection Systems.<br />

LAYER FLOOR OF FACILITY SLOPES OF FACILITY<br />

Secondary Liner 3.1-ft thick soil liner 3.1-ft thick soil liner<br />

______________60-mil, smooth IWPE liner 60-miu, textured HDPE liner<br />

Secondary Leachate Geonet Geonet-Geotextile<br />

Collection System 16-oz.Iyd 2 geotextile Goopst<br />

1.0-ft thick layer of drainage<br />

gravel<br />

1 6-ozlyd 2 geotextile _____________<br />

Primary Liner 1.5-ft thick soil liner 60-mil, textured HDPE liner<br />

_____________60-mil,<br />

smooth HDPE liner<br />

Primary Leachate Geonet Geonet-Geotextile<br />

Collection System 16otd etxieGeocomposite<br />

1.0-ft thick layer of drainage<br />

gravel<br />

7-oz/yd 2 geotextile<br />

____________<br />

rOperations Layer 3.0-ft thick gravel/eolazi sand 3.0-ft thick Eolian sand<br />

The leachate removal systems included pumps, HDPE piping, stainless steel piping, and a<br />

leach ate temporary storage tank.<br />

1.3 PROJECT SPECIFICATIONS<br />

The work performed for the Project W-025 construction project was completed according to the<br />

following documents, plans, and specifications:<br />

" Material Spoecifications and Construction Requirements for the Radioactive Mixed<br />

Waste Land Disposal facility. Non-Drae-Off. Project W025, Revision 2 prepared for<br />

the U.S. Department of Energy-Richland Operations Office, Contract No. DE-AC06-<br />

89RL 1615, by Golder Associates Inc., dated May 26, 1993.<br />

* Construction Plans for Radioactive Mixed Waste (RMW) Land Disposal Facility, Non-<br />

Drag-Off. Project W-025. prepared by Golder Associates Inc., dated May 21, 1993.<br />

93341354 3

'6 i<br />

WHC-SD-W025-RPT-0I, Rev. 0<br />

" SW - Well graded sand<br />

" SP' - Poorly graded sand<br />

" SM - Silty sand<br />

* SC - Clayey sand<br />

The results of the preconstruction materials evaluations indicated that the tested samples met the<br />

requirements of the specifications for both backffll materials and operations layer materials. Ile<br />

results of these tests are presented in Appendix D- 1.<br />

2.2 SOIL LRNER<br />

Approximately 20,000 cubic yards of soil liner material were prepared between October 4, 1993<br />

and November 15, 1993 for use in the Project W-025 test tills, <strong>sec</strong>ondary soil liner, and primary soil<br />

liner. The soil liner material consisted of an admixture (admix) of eolian sand stockpiled during<br />

landfill excavation and imported bentonite. A nominal bentonite content of 12 percent with an<br />

allowable range of I I percent to 14 percent (by weight) was required by the project specifications.<br />

American Colloid Company of Upton, Wyoming, supplied the bentonite used in the admix. Prior to<br />

mixing, prcconstrtion testing of the admix components was required.<br />

2-2-1 Bolimu Sand<br />

Two sets of grain-size determinations were performed on samples of eclian sand before the sand<br />

was mixed with bentonite. During the excavation of Project W-025, the eolian sand was sampled and<br />

tested as the material was stockpiled. This first set of grain-size determinations was performed to<br />

verify that the stockpiled ealian sand was suitable for use as soil liner material, backfill material, or<br />

operations layer material. Just prior to mixing the stockpiled eolian sand with bentonite, a <strong>sec</strong>ond set<br />

of grain-size determinations was performned. The <strong>sec</strong>ond set of tests was performed to determine the<br />

percentage of fines (minus #200-sieve particles) in each sample. This percentage of fines in the sand<br />

was used, along with the percentage of fines in the sand-bentonite admix, to determine the bentonite<br />

content of the admix. Less than 20,000 cubic yards of eolian sand were admixed with bentonite, and<br />

the tests performed on the eolian sand resulted in an approximate frequency of one test for every 500<br />

cubic yards of eolian sand used in the admix, exceeding the specified requirement of one test for every<br />

1,000 cubic yards of eolian sand used. The frequency of the preconstruction tests performed on the<br />

eolian sand is summarized in Table 4.<br />

Table 4. Eolian Sand Preconstruction Test Sumrnry.<br />

NM1UM<br />

1ET TESTS<br />

TESTS<br />

FREQUENCY ______ ____ REQUMEEDJ PER~FORMED<br />

One Test IParticle Size (ASTM D)422) 20 140<br />

The tests on the eolian sand were performed by GCS personnel in the onsite soils laboratory.<br />

The results of these tests are presented in Appendix D-2 and show that the tested samples met the<br />

project specifications.<br />

933-1354 9

WHC-SD-.W025-RPT-001, Rev. 0<br />

2.2.2 Bentonite<br />

As bentonite was delivered to the site, samples of the bentonite were periodically tested to<br />

verify that the bentonite's properties were consistent with the specified properties for 91-barrel yield<br />

bentonite. A total of 3,743.3 tons of bentonite were delivered to the jobsite, and nine samples were<br />

tested, resulting in an approximate frequency of one preconstruction test for every 416 tons of<br />

bentonite delivered to the site. This testing frequency exceeded the required frequency of one test for<br />

every 500 tons of bentonite delivered. A summary of tests performed on the bentonite is presented in<br />

Table 5.<br />

Table 5. Bentonite Preconstruction Test Summary.<br />

MINTUM TESTS 3 TEST'S J TESTS<br />

FREQUENCY REQUIRED PERFORMED<br />

One Test Fines Content (API 13A, Sec 4)<br />

Per Filtration (API 13A, Sec 4) 8 9<br />

500 Tons Viscosity (API RP 13B, Sec; 2.3)*<br />

Free Swell (USP-NF-XVII<br />

____________<br />

* Specifications indicated API B3A, Sec 4 (Direct indicating viscometer). American<br />

Colloid established a correlation between the direct indicating viscometer and the Marsh<br />

funnel viscosity. Therefore, API RI' 1313, See 2.3 (Marsh funnel) was used to determine<br />

the viscosity. A copy of the correlation between the two methods of viscosity<br />

meaurement is included in Appendix D-3.2.<br />

The bentonite preconstruction tests were performed by GCS personnel in the onsite soils<br />

laboratory. The results of the tests indicated that the tested bentonite, samples met the requirements of<br />

the specifications. A summnary of the bentonite test results is presented in Appendix D-3.1.<br />

Thie specifications required the manufacturer to submit a bentonite yield certificate for every 500<br />

tons of bentonite delivered to the site. Thirty-nine rail cars delivered a total of approximately 3,743<br />

tons of bentonite, and the supplier submitted 31 certificates of analysis, resulting in an approximate<br />

frequency of one certificate of analysis for every 121 tons of bentonite delivered. OCS reviewed the<br />

certificates and verified that the bentonite conformed to the specifications. Copies of the certificates of<br />

analysis are included in Appendix D-3.3.<br />

2.2.3 Admix<br />

After the completion of the mixing of bentonite, eolian sand, and water, but prior to the<br />

placement of the material, preconstruction tests were performed on the admix. The specifications<br />

required an admix moisture content of I percent to 5 percent above the optimum moisture content, a<br />

bentonite content o~ ;I1 percent to 14 percent, and a hydraulic conductivity (permeability) of less than<br />

or equal to I x 10- cm/s.<br />

Preonstruction moisture content tests were performed at an approximate frequency of one test<br />

for every 513 cubic yards of admix produced, exceeding the specification's requirement of one<br />

moisture test for every 1,000 cubic yards of admix produced. The admix was tested for bentonite<br />

933-1354 10

- L.I)~L/lj U<br />

WHC-SD-W025-RPT-001, Rev. 0<br />

content at an approximate frequency of one test for every 833 cubic yards of admix produced,<br />

exceeding the specification's requirement of one bentonite content test for every 1,000 cubic yards of<br />

admix produced.<br />

A suite of three tests, including a laboratory recompacted hydraulic conductivity test, a<br />

Standard Proctor moisture-density test, and an Atterberg Limits test was performed on each of six<br />

samples of the admixture, resulting in an approximate testing frequency of one suite of tests for every<br />

3,333 cubic yards of admix produced, and exceeding the specification's requirement of one suite of<br />

these tests for every 5,000 cubic yards of admix produced. The reconipacted hydraulic conductivity<br />

tests were performed by GAI's soils laboratory, located in Redmond, Washington. Standard Proctor<br />

and Atterberg Limits preconstruction tests were performed in GCS's onsite soils laboratory. The<br />

preconstruction testing frequency for the admix is summarized in Table 6..<br />

Table 6. Admix Preconstruction Test Summary.<br />

MINIMUM TESTS I TESTS TESTS<br />

FREQUENCY IREQUIRED PERFORMED<br />

One Test Moisture Content (ASTM D22 16) 20 39<br />

Per<br />

1,000 yd 3 Bentonite Content (ASTM D422) 20 24<br />

One Test Standard Proctor (ASTM D698)<br />

Per Atterberg Limits (ASTM D43 18) 4 6<br />

5,000 yd' Permeability (ASTM D5084) _______ _______<br />

-* The preconstruction test results indicated that the tested samples met the requirements of the<br />

project specifications. The results of these conformance tests are presented in Appendix D-4.<br />

Preconstruction laboratory testing indicated that the designed admixture; when properly mixed,<br />

moisture conditioned, placed, and compacted; would meet the project permeability requirement of less<br />

than or equal to I x 10"' crn./s. CQA tests on test fills and a Sealed Double-Ring Infiltrometer (SDRI)<br />

test demonstrated that the contractor's equipment and methods were capable of preparing, placing,<br />

and compacting the admix such that the specified permeability could be achieved. The results of tests<br />

performed on the test fills, and the results of the SDRI test are presented in GCS's report Oualitv<br />

Assurance, Observation and Testing. Soil Liner Tost Fill and SDRI Test. Radioactive Mixed Waste<br />

Land Disposai Facility. Noi-Drag-Off. Proiect W-025, dated May, 1994, and presented in<br />

Appendix U.<br />

2-3 GRAN4ULAR DRAINAGE MATERIAL<br />

Two types of granular drainage media were used in the drainage layers for both the <strong>sec</strong>ondary<br />

and primary leachate collection systems. Drainage gravel, generally a sandy pea-gravel, was used on<br />

the floor of each of the systems; and sump gravel, generally a clean, medium-sized gravel, was used<br />

in the sump of each system. Prior to the use of these materials, samples were obtained from the<br />

supplier, ACME Materials and Construction Co., of Richland, Washington, and preconstruction tests<br />

were performed. Preconstruction testing of the drainage gravel and sump gravel included a suite of<br />

933-1354 11

WHC-SD-W025-RPT-001, Rev. 0<br />

three tests: Sieve analysis; permneability; and slake durability. The suite of preconstruction tests was<br />

performed on four samples of the drainage gravel and one sample of the sumup gravel, resulting in<br />

preconstruction testing frequencies of one suite of tests for every 450 cubic yards of drainage gravel,<br />

and one suite of tests for every 250 cubic yards of sump gravel. These preconstruction testing<br />

frequencies exceeded the specification's required testing frequency of one suite of tests for every 500<br />

cubic yards of gravel. The sieve analyses 'were performed in GCS's onsite soils laboratory.<br />

'Permetability tests were performed by GAI's soils laboratories located in Redmond, Washington, and<br />

Mt. Laurel, New Jersey. A simulated leachate was used during the slake durability tests, which were<br />

performed by GAI's soils laboratory located in Redmond, Washington. The preconstruction testing<br />

frequencies for the granular drainage materials are summarized in Table 7.<br />

Table 7. Granular Drainage Material Preconstruction Test Summary.<br />

MINIMUM TESTS TESTS I TESTS<br />

FREQUENCY j _REQUIR.EDj PERFORMED<br />

Drainage Gravel<br />

Particle Size (ASTM C136)<br />

One Test Permeability (ASTM D2434) 4 4<br />

Per Slake Durability (ASTM D4644)<br />

500 yd' _______<br />

Sun Gravel<br />

Particle Size (ASTM C 136)<br />

One Test Permeability (ASTM D2434) 1 1<br />

Per Slake Durability (ASTM D4644)<br />

500 yd' I _ _ _ _ _ _ _ _ _ _ _ _ _ I _ _ _ _ _ _ _ __ _ _ I__<br />

The preconstruction test results indicated that the sampled granular drainage materials met the<br />

requirements of the specifications. The results of these preconstruction tests are presented in<br />

Appendix D-5.<br />

2.4 HDPE GEONEMEBRANE<br />

The geomembrane liner delivered to the site was high density polyethylene (HDPE),<br />

manufactured by SLT North America, Inc. (SLT), of Conroe, Texas. Three types of this material<br />

were delivered between October 29, 1993, and January 12, 1994, and included the following:<br />

" Textured, 60-mil thick, HDPE geomembrane liner (for use on the slopes and in the<br />

sump of the landfill)<br />

* Smooth, 60-mul thick, HDPE geomemnbrane liner (for use on the floor of the landfill1)<br />

* Smooth, 8O-mil thick, HDPE geomembrane liner (for lining beneath the truck<br />

unloading area and lining the concrete containment areas around the leachate tank)<br />

During the manufacture of the above HDPE liner materials for Project W-025, a GCS<br />

representative visited SLT's manufacturing plant on four occasions to review the manufacturing<br />

933-1354 12

WHC-SD-W025-RPT-01, Rev. 0.<br />

process, quality control, laboratory facilities, and testing procedures. During one visit, GCS's<br />

representative observed an excessive amount of recycled regrind being added to the resin, and brought<br />

this to the attention of the manuifacturer. The manufacturer opted to prepare a new batch of resin for<br />

material production for Project W-025. The manufacturer certified that no more than two percent<br />

recycled regrind had been added to the resin for any of the HDPE liner material produced for this<br />

project. A Surveillance Inspection Report was written by the GCS representative for each of the four<br />

manufacturing plant visits. Copies of these reports are included in Appendix E-1.<br />

Approximately 362,000 square feet of textured, 60-mil thick, HDPE geomembrane liner;<br />

33,500 square feet of smooth, 60-mil thick HDPE liner; and 25,200 square feet of smooth, 80-mul<br />

thick HDPE liner were delivered to the site. These materials were sampled and tested by GCS for<br />

conformance with the project specifications. Ten rolls of the textured material were sampled and<br />

tesed, resulting in an approximate frequency of one conformance test for every 36,200 square feet of<br />

textured HDPE geomernbrane liner delivered to the site. One 60-mul thick roll of the smooth, HDPE<br />

liner material was sampled and tested, resulting in an approximate frequency of one conformance test<br />

for every 33,500 square feet of material delivered. Three samples, one from each resin lot delivered<br />

to the site, of the 80-mil thick, smooth, HDPE liner material were sampled and tested, resulting in an<br />

approximate frequency of one conformance test for every 8,400 square feet of material delivered.<br />

The conformance testing frequencies met or exceeded the specifications' requirement of a minimum of<br />

one conformance test for every 50,000 square feet of material delivered to the site, or a minimum of<br />

one conformance sample for each lot of material delivered.<br />

Additional conformance testing of the material properties of the geomembrane included<br />

fingerprinting analyses and direct shear testing. Fingerprinting analyses, including tests of the<br />

material's specific gravity, melt index, and crystallinity were performed on two samples of the<br />

geomembrane. Two direct shea tests were performed on samples of the textured HDPE liner and the<br />

soil liner material as required by the specifications. A summary of the HDPE liner conformance<br />

testing frequency is presented in Table 8.<br />

Table 8. HDPE (Jemembrane Conformance Test Summary.<br />

MINIMUM TESTS j TESTS TESTS<br />

FREQUENCY I______________ REQUIRED PERFORMED<br />

TexureQ60mil Sp. Gravity (ASTM D792 or D1505)<br />

Carbon Black Content (ASTM D1603)<br />

One Test per Carbon Black Dispersion (ASTM 10 10<br />

.50,ODO fr2or D 1603)<br />

One test/Lot Thickness (ASTM D1593)<br />

Tensile Properties (ASTM D638)<br />

Two Tests Total Friction Angle of Interface with Admix 2 2<br />

(Direct Shear Method)<br />

_____________<br />

933-1354 13

WHC-SD-W025-RPT-001, Rev. 0<br />

MINIMUM TESTS TESTS! TESTS<br />

FREQUENCY 1REQUIRED PERFORMED<br />

Smooth 60rmiI Sp. Gravity (ASTM D792 or D1505)<br />

Carbon Black Content (ASTM D 1603)<br />

One Test per Carbon Black Dispersion (ASTM11<br />

50,000 ft 2 or D 1603)<br />

One test/Lot Thickness (ASTM D1593)<br />

Tensile Properties (ASTM D)638)<br />

Smooth 80-mul Sp. Gravity (ASTM 1D792 or D)1505)<br />

Carbon Black Content (ASTM D1603)<br />

One Test per Carbon Black Dispersion (ASTM 3 3<br />

50,000 ft' or D1603)<br />

One test/Lot Thickness (ASTM D1593)<br />

Tensile Properties (ASTM D)638)<br />

The conformance samples were tested by GCS's geosynthetics laboratory located in Duluth,<br />

Georgia and the direct shear tests were performed at Golder Associates Ltd. soils laboratory 'located<br />

in Calgary, Alberta. The results of the direct shear tests were reviewed by GCS CQA personnel and<br />

the GAI Design Engineer. The direct shear test results met the requirements of the specifications.<br />

The remainder of the conformance test results were reviewed by GCS for compliance with the project<br />

specifications. With only one exception, the tested material met the requirements of the<br />

specifications. One roll of smooth, 8O-mul thick, HDPE geotnembrane liner from a different lot than<br />

those used was rejected because the conformance test results indicated that the density and carbon<br />

black content were lower than specified. This roll was rejected for use in Project W-025. The<br />

results of the conformance tests are presented in Appendix E-2. An inventory of the rolls of IIDPE<br />

geomnembrane liner delivered to the site is also included in Appendix E-2.<br />

The manufacturer of the geomembrane (SLT North America) provided the following<br />

documentation for the HDPE liner materials delivered to the site:<br />

0 Fingerprinting analytical data<br />

* A report, issued by Geosyntec Consultants, of Atlanta, Georgia, which presents the<br />

results of friction angle tests<br />

* Certification that HDPE liner materials meet the requirements of the specifications<br />

0 Quality Control (QC) Roll Test Data Report for each roll of HDPE geomnembrane<br />

liner<br />

* Certificate of Analysis for each resin lot used to produce the delivered rolls<br />

a<br />

Certification that the resin contains no reclaimed polymer and ]ess than two percent of<br />

recycled trim<br />

933-1354 14

WHC-SD-W025-RPT-00l, Rev. 0<br />

*Certification that the materials passed the 2000-hour Environmental Stre'ss Crack<br />

Resistance test<br />

" Certification that the materials meet the specification's requirements for Resistance to<br />

Soil Buria<br />

" Certification that the welding extrudate (rod and resin) is manufactured from the same<br />

base resin type and will exhibit similar physical characteristics as the geomembrane<br />

* Certification that the material contains only virgin polyethylene resin and carbon black<br />

" Certification of the consistency of the material<br />

GCS personnel and/or GAl Design Engineers reviewed the above documents for conformance<br />

to the project specifications. Copies of these certificates are included in Appendix E-3.<br />

2.5 GEONET<br />

The HDPE geonet delivered to the site was TENAX CE-2, manufactured by TENAX<br />

Corporation, of Jessup, Maryland. Approximately 50,700 square feet of geonet were delivered to the<br />

site on October 13, 1993. A total of two rolls were sampled and tested for conformance with the<br />

project specifications, resulting in an approximate testing frequency of one conformance test for every<br />

25,350 square feet of material delivered to the site, exceeding the specification's requirement of one<br />

conformance test for every 50,000 square feet of geonet delivered to the site. The geonet<br />

conformance testing frequency is summarizeid in Table 9.<br />

Table 9. Geonet Conformance Test Summary.<br />

MINIMUM 1TESTS TESTS I TESTS<br />

FREQUENCY IREQUIRED PERFORMED<br />

ISpecific Gravity (ASTM D792 or<br />

One Test per DI1505) 2 2<br />

50,000 ft 2 Thickness (ASTM D1777)<br />

Transmissivity (ASTM D4716)<br />

Mass per Unit Area (ASTM D3776) _______ _______<br />

The conformance samples were tested by GCS's geosynthetics laboratory in Duluth, Georgia.<br />

GCS reviewed the conformance test results for compliance with the project specifications. The<br />

conformance tests indicated that the tested samples met the requirements of the project specifications.<br />

The conformance test results are given in Appendix F-1. An inventory of the rolls of geonet<br />

delivered to the site is also included in Appendix F-i.<br />

The manufacturer of the geonet (TENAX Corporation) provided certification and quality<br />

control (QC) data for the material delivered to the site. GCS reviewed these documents for<br />

compliance with the specifications. With one exception, the documents indicated compliance with the<br />

specifications. The manufacturer's QC tests indicated that the specific gravity of the geonet was<br />

933-1354 15

W14C-SD-W025-RPT-O01, Rev. 0<br />

0.946, whereas G3CS's conformance tests indicated a geonet specific gravity of 0.940 to 0.94 1. The<br />

specifications require a geonet specific gravity less than that of the 60-mil thick HDPE geomembrane<br />

upon which the geonet was to be installed. GCS's conformance tests on the 60-mil geomembrane<br />

indicated specific gravities ranging from 0.942 to 0.945, and the geomembrane manufacturer's<br />

(SLT's) QC tests on the 60-mul geornernbraxie indicated specific gravities ranging from 0.942 to<br />

0.947. GCS's conformance tests on the geonet indicated that the specific gravity of the geonet met<br />

the requirements of the specifications, whereas TENAX'es QC tests indicated specific gravity of the<br />

geonet was greater than the specific gravity of the geornembrane. TENAX wrote a letter which<br />

clarified their position that interlaboratory precision and the accuracy of the standard test method were<br />

the most probable causes for the discrepancies. TENAX also indicated that valid comparisons of the<br />

specific gravities of the geonet and geomrnbrane can only be made if both materials are tested by the<br />

same testing laboratory. GCS personnel and GAI design personnel reviewed thc data and the letter<br />

from TENAX, and determined that, based on the data from a common laboratory, the geonet's<br />

specific gravity met the requirements of the specifications. The manufacturer's quality control<br />

documents and the letter regarding the geonets' specific gravity are included in Appendix F-2.<br />

2.6 GEOTEXTILE<br />

The geotextile materials delivered to the site were Nicolon S700 (seven-oz/yd' fabric) and<br />

Nicolon S 1600 (1 6.ozlyd 2 fabric) manufactured by Nicolon Corporation, of Norcross, Georgia. The<br />

geotextiles are non-woven, needle-punched, polypropylene. Approximately 72,000 square feet of S700<br />

geotextile were delivered to the site on October 4, 1993, and on January 12, 1994, and 112,500<br />

square feet of S 1600 geotextile were delivered to the site on October 4, 1993. Two rolls of S700<br />

fabric, and three rolls of the S 1600 fabric were sampled and tested for conformance with the project<br />

specifications, resulting in approximate frequencies of one conformance test for every 36,000 square<br />

feet of seven-ounce material, and one conformance test for every 37,500 square feet of the 16-ounce<br />

material. These conformance testing frequencies exceed the specified minimum frequency of one<br />

conformance test for every 50,000 square feet of material. The geotextile conformance testing<br />

frequencies are summarized in Table 10.<br />

Table 10. Geotextile Conformance Test Sumnmary.<br />

MINIMUM TESTS I TESTS TESTS<br />

FREQUENCYj _REQUIRED_ PERFORMED<br />

5even-oz/vd 2 1 Mass per Unit Area (ASTM D3776)<br />

Fabric Grab Strength (ASTM D4632)<br />

Tear Strength (ASTM D4533)<br />

Burst Strength (ASTM D37 86)<br />

One Test per Puncture Strength (ASTM D4833)<br />

50,000 ft2 Thickness (ASTM D1777)<br />

Permnittivity (ASTM D4491)<br />

2 -2<br />

____________ACS<br />

(ASTM D4751)______<br />

933-1354 16

WHC-SD-WO2S-RPT-O01, Rev. 0<br />

MJNIMvWM TESTS TESTS TESTS<br />

FREQUENCY ___________~ REQUIR.ED jPERFORMED<br />

16-oztvd 2 Fabric Mass per Unit Area (ASTM D3776)<br />

Grab Strength (ASTM D)4632)<br />

Tear Strength (ASTM D)4533)<br />

One Tever Burst Strength (ASTM D)3786) 3 3<br />

50,00Puncture Strength (ASTM D)4833)<br />

Thickness (ASTM D1777)<br />

Permittivity (ASTM D4491)<br />

AOS (ASTM D4751)<br />

__________<br />

The conformnance samples were tested by GCS's geosynthetics laboratory in Duluth, Georgia.<br />

GCS reviewed the conformance test results for compliance with the specifications. The conformance<br />

test results indicated that the tested samples of the materials delivered to the site on October 4, 1993,<br />

including 48,000 square feet of S700 fabric and 112,500 square feet of S 1600 fabric, met the<br />

requirements of the specifications. These materials were designated for use inside the landfill.<br />

A conformance test result for a sample of the 24,000 square feet of S700 fabric delivered to the<br />

site on January 12, 1994, indicated that the sample did not meet, the specification's minimum 2<br />

requirement for thickness. This material was rejected for use in Project W-025 where seven-oz/yd 2<br />

- gotextile was specife. Due to a shortage of S 1600 fabric, which was specified for use as a cushion<br />

layer on the geomernbrane liner in the truck unloading area, three layers of the deficient S700 fabric<br />

were designated for use as replacement material for the S 1600 fabric in the truck unloading area by<br />

the Design Engineer (Appendix C-3). The use of S700 fabric was allowed in the truck unloading area<br />

because three layers of the deficient S700 fabric would provide a thicker cushion on the geotnembrane<br />

than would a single layer of the S1600 fabric.<br />

The conformance test reslts for the geotextiles are presented in Appendix G3-1. An inventory<br />

of the rolls of geotextile delivered to the site is also included in Appendix G3-1. In addition to<br />

reviewing conformance test results, GCS personnel reviewed manufacturer's certifications and QC data<br />

for compliance with the specifications for the geotextiles. The manufacturer's certification and quality<br />

control documents for the delivered materials are included in Appendix G-2. Additionally, GCS5<br />

reviewed the manufacturer's certification of the thread used for sewing the geotextiles. This document<br />

is also included in Appendix G3-2.<br />

2.7 GEOCOMIPOSITE<br />

The geocomposite delivered to the site was SLT's GS-228. The geocomposire consisted of<br />

Nicolon 5700 geotextile thermally bonded to the top and bottom of TENAX CE-2 geonet<br />

Approximately 355,700 square feet of GS-228 geocornposite were delivered to the site between<br />

November 8, 1993 and January 12, 1994. Eight rolls of GS-228 were sampled, and the geotextile<br />

component was tested for Apparent Opening Size (AOS) to determine conformance with the project<br />

specifications. The resulting testing frequency was approximately one conformance test for every<br />

44,500 square feet of geocornposite delivered to the site, exceeding the specification's requirement of<br />

one conformance test for every 50,000 square feet of geocomposite.<br />

933-1354 17

WHC-SD-W025-RI'T-00l, Rev. 0<br />

in addition to the above conformance testing of the geocomzposite, two friction angle tests,<br />

using the direct shear method, were performed on the interface between the geocomposite material<br />

and the textured HDPE liner. Two friction angle tests were also performed on the interface between<br />

the geocomposite and the operations layer soil. The geocomposite conformance testing frequencies<br />

are summarized in Table 11.<br />

Table i1. Geocomposite Conformance Test Summary.<br />

NMMUM T TSf TESTS TESTS<br />

FREQUENCY 11REQUIRED PERFORMED<br />

One Test per AOS (ASTM D4751) 8 8<br />

50,000 ft 2 Friction Angle of Interface<br />

Two Tests Total with Textured HDPE 2 2<br />

______________ (DiectShearMethod)_______ _______<br />

Friction Angle of Interface<br />

Two Tests Total with Operations Layer 2 2<br />

______________ (DirectShearMethod)_______<br />

The ACS conformance tests were performed by GCS's goosynthetics laboratory, located in<br />

Duluth, Georgia. The direct shear tests were performed by Golder Associates Ltd. soils laboratory,<br />

located in Calgary, Albert. The test results were reviewed for conformance to the specifications by<br />

GCS personnel and the GAI Design Engineer, and are presented in Appendix-H-i. The tested<br />

samples met the project specifications. An inventory of the rolls of geocomposito delivered to the site<br />

is included in Appendix H-1.<br />

In addition to reviewing conformance test results, GCS reviewed manufacturer's certification<br />

and QC tast results for the geocoinposite. The manufacturer's infommion indicated that the firt 50<br />

delivered rolls of geocomposite were manufacturered using a geotextile that did not meom the<br />

requirements of the project specifications. These 50 rolls of geocomposite were rejected. The<br />

manuftcume then produced geowtmposite composed of the specified materials, and shipped the new<br />

geocomposite to the jobsite. The manufacturer's QC test data for the new material indicated that<br />

several rolls failed the manufacturer's QC tests. Assuming that the manufacturer tested samples from<br />

the trailing edge of each roll of material, and that the traiing edge of one roll is the same as the<br />

leading edge of the next con<strong>sec</strong>utively produced roll of material, deficient material on the trailing<br />

edge (outside) of a roll of material would also indicate deficient material on the leading edge (inside)<br />

of the next con<strong>sec</strong>utively produced roll. Therefore, GCS determined that the failing tests affected a<br />

total of eight rolls of the new material. All eight of these rolls of geocomposite were also rejected by<br />

GCS for use in Project W-025, and the contractor removed all of the rejected rolls from the jobsite.<br />

The manufacturer's QC test data and certification of the geocomposite are included in Appendix H1-2.<br />

Deihur arranged for the performance of two friction angle tests each for the interface between<br />

the geocomposite and the textured HDPE liner, and for the interface between the geocomposite and<br />

the operations layer material. GCS CQA personnel and GAI Design personnel reviewed the<br />

contractor's test results for conformance to the requirements of the specifications. The results of the<br />

contractor's friction angle tests for the geocornposite/textured geomembrane and<br />

933-1354 18

WHC-SD-WO25-RPT-OO1, Rev. 0<br />

interfaces are included in Appendix E-3 with the friction angle data for the tests performed on the soil<br />

liner/textured geomembrane interface.<br />

2.8 HIJPE PEPE AND STAINLESS S7E1M PIP<br />

The HDPE pipe delivered to the site was produced by Polaris Pipe Co., of Van Nuys,<br />

California, and was supplied by Industrial Plastics, Inc.. of Washougal, Washington. The<br />

specifications required no QA conformance tests for these materials. H~owever, the contractor was<br />

required to submit quality control certificates for the pipe, and qualifications of the pipe joining<br />

personnel. G3CS reviewed these documents. The documents indicated that the pipe conforms to<br />

ASTM D1248, Type MI, Class C, Category 5, Grade 34; call classification 345434C per ASTM<br />

D3350; and that the proposed joining personnels' qualifications met the requirements of the<br />

specifications. All onsite joining of the 1HDPE pipe was performed by certified personnel. Copies of<br />

the manufacturer's certificates and the qualifications of the pipe joining personnel are included in<br />

Appendix I-1.<br />

The stainless; steel pipe delivered to the site was Schedule 40 Type 316, as required by the<br />

specifications. No QA conformance -tests were required for the stainless steel pipe. However,<br />

manufacturers' certifications for the pipe are included in Appendix 1-2.<br />

2.9 TOP COURSE<br />

Top course material for Project W-M2 was supplied by ACME Materials and Construction Co.,<br />

of Richland, Washington. 'The top course was used as a road-base material on the access ramp, the<br />

perimeter road, the truck staging area, the truck unloading area, and the site entrance. Prior to<br />

construction, GCS personnel obtained samples of the top course material from the supplier, and<br />

performed the required preconstruction tests. The top course preconstruction tests are summarized in<br />

Table 12.<br />

Table 12 Top Course Preconstruction Testing Summary.<br />

M1NlMJM TESTS TESTS TESTS<br />

FREQUJENCY ___________[REQUIRED IPERFORMED<br />

One Test Particle Size (WSDOT 1991<br />

Prior to Sec. 9-03.9.3)1<br />

Construtction Mod. Proctor (ASTM D1557)<br />

The results of the preconstruction tests on the top course material indicated that the tested<br />

sample met the requirements of the specifications. The test results are presented in Appendix D-6.<br />

2.10 OPERATIONS LAYER<br />

The operations layer materials for Project W-025 were segregated and stockpiled as excavation<br />

of the facility progressed. Eolian sand was stockpiled, and designated for use as operations layer<br />

material on the slopes of the facility, for use in the admix, and for use as general fill material. Sandy<br />

gravel to grav'elly sand was stockpiled, and designated for use as operations layer material on the floor<br />

933-1354 19

WHC-SD-W025-RPT-001, Rev. 0<br />

of the facility, and for use as general fill material. GCS personnel performed 21 preconstruction sieve<br />

analyses and hydrometer tests on the eolian sand, and two preconstruction sieve analyses and<br />

hydrometer tests on the gravelly materials as they were stockpiled. Based on the Design Engineer's<br />

estimate of 15,690 cubic yards of soil required for use as operations layer material, the 23<br />

preconstructiori tests resulted in a frequency of one preconstruction .test for every 682 cubic yards of<br />

operations layer material. This testing frequency exceeded the specification's requirement of one<br />

preconstruction test for every 2,000 cubic yards of operations layer material. The preconstruction tests<br />

are summarized Table 13,<br />

Table 13. Operations Layer Preconstruction Testing Summary.<br />

IND"U TEST1S TESTS TESTS<br />

FREQUENCY ____________ REQUIED jPERFORMED<br />

One Testper Hydrometer and Sieve 8 23<br />

2,000 yd3 (ASTM D422) I_______<br />

The specifications required that the operations layer material meet the specification's<br />

requirements for backfill material, previously discussed in Section 2.1 of this report. The results of the<br />

preconstruction tests indicated that the tested samples met these requirements. The preconstruction. test<br />

results for the operations layer material are presented in Appendix D-7.<br />

933-1354 20

WHC-SD-W025-RPT-001, Rzv. 0<br />

3.0 EXCAVATIONISUBGRADE PREPARATION<br />

Project W-025 was excavated by Deihur Industries, Inc., of Port Angeles, Washington, in<br />

loose to compact eolian sand, and dense to very dense sand and gravel deposits. Deihur began the<br />

excavation on September 13, 1993, and completed the excavation on September 25, 1993. The<br />

following equipment was used during the excavation and subgrade preparation phases of construction:<br />

* Hitachi EX 1000 Excavator<br />

* 3 International, 50-ton, Payhiauler, End-Dump Trucks<br />

* Caterpillar D-9 Bulldozer<br />

* Caterpillar D-5 Bulldozer<br />

* John Deere (JD) 772A Grader<br />

* 3500-Gallon Water Truck<br />

" Ray Go Rascal 410A, Smooth-Drum, Vibratory Compactor<br />

* Caterpillar 988B Loader<br />

3.1 GEOLOGIC SIT CONDITIONS<br />

The excavation of the Project W-025 Landfill was monitored to confirm the<br />

geological/geotechnical conditions described in the design report and to confirm that the excavated<br />

materials were placed in the proper stockpiles. Upon completion of the excavation, the landfill<br />

subgrade was geologically mapped. 'The results of the geological mapping are described below.<br />

3.1.1 General<br />

The Project W-025 Landfill is located within the 200 West area of the <strong>Hanford</strong> Nuclear<br />

Reservation. The <strong>Hanford</strong> Nuclear Reservation lies within the Columbia Plateau geological province.<br />

The Columbia Plateau province is defined by the lateral extent of the Columbia River Basalt Group, a<br />

sequence of Miocene basaltic lava flows that cover an estimated 63,000 square miles of the states of<br />

Washington, Oregon, and Idaho. Large-scale tectonic deformation in the plateau has resulted in the<br />

formation of several broad structural and topographic basins. The <strong>Hanford</strong> Reservation lies within<br />

the Pasco Basin.<br />

The Pasco Basin represents a topographic low within the Columbia Plateau. The confluence of<br />

the Columbia, Snake, Yakcima, and Walla Walla Rivers occurs in the Pasco Basin. Late Pleistocene<br />

catastrophic flooding and Holocene eolian processes have created an extensive system of channel bar<br />

deposits, flood plains, sand dunes, and loess deposits within the central portion of the basin.<br />

Significant geomorphic features within the central part of the basin include the Cold Creek Bar on<br />

which the 200 West area is located, the Central <strong>Hanford</strong> Sand Plain, and the Cold Creek-Dry Creek<br />

Alluvial Plain.<br />

The geology of the Pasco Basin is dominated by a thick sequence of tholeiitic basalt flows<br />

collectively known as the Columbia River Basalt Group. These flows erupted during the Miocene<br />

Epoch, between 6 to 17 million years before the present. Interbedded with the basalt flows are a<br />

series of epiclastic and volcaniclastic sediments generally referred to as the Ellensburg Formation.<br />

Overlying the Columbia River Basalt Group within the Pasco Basin are Miocene to Holocene fluvial,<br />

glaciofluvial, and eolian sediments. These sediments make up the Miocene-Pliocene Ringold<br />

933-1354 21

WHC-SD-W025-RPT-001, Rev. 0<br />

Formation and the informally named Pleistocene <strong>Hanford</strong> formation. Unconsolidated, H~olocene<br />

fluvial sediments, sand dune, and loess are the predominant surficial deposits.<br />

3.1.2 Geologic Mapping<br />

The geologic mapping of the Project W-025 excavation was performed by an engineering<br />

geologist with GCS who was familiar with the geology of the <strong>Hanford</strong> region. The field geologic<br />

mapping was performed between October 15 and October 28, 1993. The base map for the geologic<br />

mapping was Drawing No. H-2-131589, revision 2, "Subgrade Grid Points, RMW Land Disposal<br />

Facility, Non-Drag-Off", prepared by Golder Associates Inc., dated May 21, 1993. Stratigraphic<br />

contacts were located in the field by measuring directly from marked survey grid points in the<br />

Project W-025 excavation. The survey grid points were spaced every 25 feet and allowed for<br />

relatively accurate location of stratigraphic contacts in the excavation.<br />

In general, the geologic units were well exposed in the excavation side walls and floor. Minor<br />

cleaning of the exposure using a shovel was required in several instances to accurately locate the<br />

stratigraphic contacts or to collect representative samples of the geologic units for description.<br />

The geologic map for the Project W.-025' excavation is shown in Figure 3 and the cross-<strong>sec</strong>tions<br />

for the cell are shown on Figure 4.<br />

3.1.3 Geologic Units Encountered<br />

The geologic units exposed in the Project W-025 excavation, from youngest to oldest, are as<br />

follows:<br />

* Recent Eolian Sand: Quaternar-y, wind deposited, loose to compact, olive gray, silty,<br />

fine sand was encountered in the upper portion of the excavation. The unit had a<br />

basal elevation ranging from approximately 691 on the west end to 683 on the east<br />

end. A six-inch thick volcanic ash layer was observed interbedded with the eolian<br />

sand in the northeast corner of the excavation. The volcanic ash layer ranged in<br />

elevation from approximately 691 to 693.<br />

* Glaciofluvial Flood Denosit: Underlying the Recent Eolian Sand was dense to very<br />

dense, olive black, gravelly, fine to coarse sand. This, in turn was underlain by<br />

dense, moderate olive brown, fine sandy silt, which was underlain by dense to very<br />

dense, fine to coarse sand in which the Project W-025 excavation was terminated.<br />

The base of the gravelly sand unit ranged from approximately 677 on the west to 672<br />

on the eat. The base of the sandy silt unit ranged from approximately 675 on the<br />

west to 670 on the east.<br />

3.2 SUBGRADE PREAPATION AND 1BACKFILL PL4CEMENT<br />

T7he subgrade of the Project W-025 excavation was prepared for installing the <strong>sec</strong>ondary lining<br />

system by grading and recoinpacting the excavation surfaces. Deihur used Caterpillar D-9 and D-5<br />

bulldozers, and a 3D 272A grader to scarify the subgrade to a depth of approximately eight inches. A<br />

water truck was used to moisture condition the scarified soils. The subgrade. soils were then<br />

933-1354 22

WHC-SD-W025-RP T-01, Rev. 0<br />

compacted to at least 90 percent of their Modified Proctor maximum dry density (ASTM D 1557)<br />

using a Ray Go Rascal 410A, smooth-drum, vibratory roller. In a few areas on the lower sideslopes<br />

of the excavation, the contractor experienced difficulty .achieving the required compaction of clean,<br />

sandy gravels. In these areas, Delhur used relatively fine-grained soils as fill material to provide a<br />

firm surface upon which the <strong>sec</strong>ondary lining system could be installed. The fill materials were<br />

moisture conditioned and compacted in the same manner as the subgrade soils.<br />

Field moisture-ensity tests were performed by GCS personnel on the compacted subgrade<br />

using a Troxier Model 3440 Nuclear moisture-density gauge (ASTM D2922 and ASTM D3017). At<br />

least one side-by-side rubber-balloon test (ASTM D2167) was performed each day, or once for every<br />

20 Troxlex tests per day, to verify the accuracy of the nuclear densometer tests. At the completion of<br />

each nuclear moisture-density test, a sample of the soil at the test location was obtained and sealed in<br />

a plastic bag for laboratory water content determination using the oven-dried method (ASM D2216).<br />

In areas where the test results indicated that the compaction did not meet the requirements of the<br />

specifications, the contractor was required to rework and recornpact the soil until passing test results<br />

were achieved. The specifications required moisture-density tests on the subgrade at a minimum<br />

frequency of one test per 10,000 square feet of surface area. The surface area of the excavation was<br />

approximately 160,000 square feet, and 32 moisture-density tests (excluding retests) were performed<br />

on the subgrade, soils, resulting in an approximate frequency of one moisture-density test for every i<br />

5,000 square feet of subgrade surface area. A summary of the test results is included in Appendix 1.<br />

An as-built survey of the excavation was performed by Permit Surveying, Inc. A CQA survey<br />

was performed by Rogers Surveying, Inc. to verify Permit's survey. GCS reviewed data from both<br />

surveys, and concluded that the CQA survey data reasonably verified Permit's data. Permit's survey<br />

indicated that all surveyed grid points were within the tolerances required by the project plans and<br />

specifications. Rogers' CQA survey data are included in Appendix T-1. Permit's Record Drawing,<br />

Subgrade As-Built, Sheet 1 of 6, is included in Volume 2 of this report.<br />

On the periphery of the excavation, subgrade preparation was required in the footprint of the<br />

perimeter road, the truck unloading area, the truck staging area, and the site entrance road. Delhur<br />

used similar equipment and methods to compact these subgrade areas to at least 90 percent of the<br />

soil's Modified Proctor maximum dry density (ASTM D1557). The peripheral area of the excavation<br />

was approximately 80,000 square feet in size, and GCS personnel performed 14 moisture-density<br />

tests. The resulting approximate frequency of one moisture-density test for every 5,714 square feet of<br />

peripheral subgrade area exceeded the specification's requirement of one test for every 10,000 square<br />

feet of subgrade area. A summary of these test results is included in Appendix J.<br />

The placement and compaction~ of approximately 4,500 cubic yards of backfill were required to<br />

establish the design grade of the site entrance, the truck staging and unloading areas, and segments of<br />

the perimeter road. Backfill material was hauled by an International, 50-ton, Payhauler, end-dump<br />

truck, or by a Caterpillar 988B front-end loader. The material was spread in maximum loose-lift<br />

thicknesses of eight inches by a JD 272A grader. The backfill was moisture conditioned using a<br />

3,500-gallon water truck, and then compacted to 90 percent of the material's Modified Proctor<br />

maximum dry density (ASTM D1557) by a Ray Go Rascal 410A smooth-drum, vibratory roller.<br />

Field moisture-density tests were performed on each lift of backfill material. A total of 58<br />

moisture-density tests were performed, resulting in a frequency of one test for every 78 yards of<br />

backfill, exceeding the specifications' requirement of one moisture-density test for every 500 cubic<br />

yards of backfill placed. A summary of the backfill moisture-density test results is included in<br />

933-1354 23

WHC-SD-W025-RPT-O01, Rev. 0<br />

Appendix J. The locations of the field moisture-density tests for the subgrade, general fill, and top<br />

course materials are shown on Figure 5.<br />

933-1354 24

WHC-SD-W025-RPT-0I, Rev. 0<br />

4.0 SECONDARY LINER SYSTEM<br />

The <strong>sec</strong>ondary liner system for the Project W-05 landfill consisted of a soil liner,<br />

geomembrane liner, and leachate collection and removal system (LCRS).<br />

4.1 SOIL LINER<br />

4.1.1 Construction<br />

The soil liner admix was prepared using onsite eclian sand and imported bentonite. The sand<br />

for the soil liner was obtained from the eolian sand stockpile located on the west side of the site. The<br />

eolian sand had been stockpiled during the excavation of the landfill. Preconstruction testing<br />

indicated that the eclian sand and the bentonite met the requirements of the specifications for use as<br />

soil l iner constituents (See Sec. 2. 1). The eolian sand, bentonite, and water were mixed in a pug mill<br />

to produce an admixture which contained approximately I11 percent to 14 percent by dry-weight<br />

bentonite, and a moisture content of 1 percent to 5 percent above the admixture's optimum moisture<br />

content, as determined by ASTM D698. After the soil liner was mixed in the pug mill, the placement<br />

of the soil liner was generally completed in the following stages:<br />

* Te soil liner was stockpiled around the edge of the excavation and allowed to<br />

moisture cure for approximately 24 hours.<br />

0 Water was applied to the subgrade just prior to the placement of the soil liner.<br />

0 The first lift of soil liner was spread in a loose-lift thickness of approximately a 12<br />

inches, using a Caterpillar D-6 dozer and a ID 450 dozer.<br />

* The soil liner was compacted to at least 90 percent of the materia's Standard Proctor<br />

maximum dry density (ASTM D698), using four, one-way passes of a Caterpillar<br />

825C self-propelled wedgefoot compactor,<br />

* Five additional lifts of soil liner were placed and spread in maximum loose-lift<br />

thicknesses of approximately 10 inches. Compaction of each lift was achieved using<br />

four passes of the Cat 825C compactor.<br />

" The top lift of the soil l iner was trimmed using a D-6 dozer equipped with low ground<br />

pressure (LGP) tracks.<br />

" The surface of the soil liner was prepared for geomembrane deployment by rolling<br />

with a Ray Go Rascal smooth-drurn vibratory roller.<br />

" The soil liner was watered as necessary during dry weather to prevent excessive<br />

drying.<br />

The placement and compaction of the first lift of soil liner commenced in the northwest corner<br />

of the landfill, and generally proceeded in a clockwise direction. Delhur completed this circular cycle<br />

six times during the placement and compaction of the six lifts of soil liner. To enable large trucks to<br />

933-1354 25

WHC-SD-W025-RPT-001, Rev. 0<br />

haul admix to the floor of the facility, the access ramp was not covered with soil liner material until<br />

just prior to the completion of the soil liner in the rest of the landfill.<br />

A total of approximately 20,000 cubic yards of admix material was produced by the pug mill.<br />

Approximately 15,150 cubic yards of this material were placed and compacted on the floor and slopes<br />

of the Project W-025 Landfill during the construction of the <strong>sec</strong>ondary soil liner.<br />

Following the completion of the placement, compaction, and trimming of the <strong>sec</strong>ondary soil<br />

liner, an as-built survey of the soil liner surface was performed by Permit Surveying, Inc., and a<br />

OQA survey was performed by Rogers Surveying, Inc. GCS reviewed the data from both surveys,<br />

and determined that Rogers' survey data reasonably verified Permit's survey data. The specifications<br />

required a minimum <strong>sec</strong>ondary soil liner thickness of 3.1 feet, measured perpendicular to the<br />

subgrade surface. Permit's survey data indicated that three of the surveyed grid points did not meet<br />

the tolerance requirements of the specifications, and that four grid points had not been surveyed.<br />

Delhur was required to rework the three areas which were initially out of tolerance. Permit then<br />

surveyed the four grid points which were missed during the first survey, and resurveyed the three<br />

areas which had been reworked. A review of the new survey data indicated that a minimum of 3.1<br />

feet of soil liner had been installed at each of the surveyed grid points. Permit's Record Drawing,<br />

Top of Secondary Admix As-Built, Sheet 2 of 6, is included in Volume 2 of this report. Roger's<br />

CQA survey data for the <strong>sec</strong>ondary soil liner are included in Appendix T-2.<br />

The trench for the <strong>sec</strong>ondary slope riser pipe was excavated using a Case 580 backhoe. The<br />

trench was trimmed using hand tools. The anchor trench in the access ramp and the anchor trench<br />

around the perimeter of the landfill were excavated using the Hitachi EX1000 excavator. The anchor<br />

trench in the access ramp was prepared for geornembrane deployment by rolling with a Ray Go<br />

Rascal 410A smooth-drum vibratory roller and a Bornag band operated smooth-drum vibratory roller.<br />

GCS observed the excavation of the anchor trenches, and confirmed that the trenches had been<br />

conistructed per the project plans.<br />

After the surface of the <strong>sec</strong>ondary soil liner had been prepared for geomembrane deployment<br />

by rolling with a smooth-drum vibratory roller, cold weather caused the top lift of soil liner to freeze.<br />

When the soil liner thawed, a sheen of mud remained on the surface. Due to concern regarding the<br />

friction angle of the interface between the geornerbrane and the muddy surface of the soil liner, the<br />

contractor was required to dry the muddy surface before deployment of the geomembrane liner was<br />

allowed to begin. Delhur used propane fueled weed-burners, mounted on a D-6 dozer, to dry the<br />

surface of the soil liner.<br />

4.1.2 Testing<br />

A total of 162 field moisture-density tests were performed at a frequency of at least one test per<br />

250 cubic yards of soil liner placed. All field moisture-density tests were conducted using a Troxlr<br />

Model 3440 Nuclear density gauge (ASTM D2922 and D3017). At least one side-by-side rubber<br />

balloon test (ASTM D2167) was conducted each day, or once for every 20 nuclear density tests per<br />

day, to verify the accuracy of the nuclear densometer tests.<br />

After completion of the nuclear moisture-density test, a sample of the soil from the density test<br />

location was obtained and sealed in a plastic bag for laboratory water content determination using the<br />

oven-dried Method (ASTM D2216) or the microwave oven method (ASTM D4643). Upon<br />

completion of the test, the hole was backfilled with soil liner material and compacted by hand. Using<br />

933-1354 26

WHC-SD-W025-RPT-0Ol, Rev. 0<br />

moisture content data obtained during construction of the test fill and during the admix preparation, a<br />

statistical analysis (regression method) was performed to determine the correction factor for correcting<br />

the microwave oven moisture content to the equivalent of the conventional oven moisture content.<br />

The microwave oven moisture method was used to allow quick determinations as to whether<br />

compaction tests were passing or failing. Conventional oven moisture determinations require<br />

approximately 24 hours for a result. Microwave oven moisture determinations require only<br />

approximately five minutes for a result. For this reason, the correlation was established. At least<br />

one side-by-side microwave moisture and conventional oven moisture test were performed each day to<br />

continually update the regression analysis.<br />

Four of the 162 moisture-density tests indicated that the moisture content of the soil liner was<br />

too dry. Deihur reworked the affected areas of the soil liner, and retests indicated acceptable<br />

moisture-density test results. The results of field moisture-density tests are summarized in<br />

Appendix K-i. Test locations are shown in Figure 6.<br />

In addition to the field tests, Shelby tubes were used -to obtain relatively undisturbed samples of<br />

the compacted soil liner. Laboratory tests were performed on the Shelby tube samples. The ends of<br />

the Shelby tubes were sealed in the field with plastic caps and were later sealed in the on-site<br />

laboratory with wax. The samples were shipped to the GA! soils laboratory located in Redmond,<br />

Washington, for permeability testing. Hydraulic conductivity tests (ASTM D5084) were performed at<br />

a frequency of at least one test for every 5,000 cubic yards of soil liner placed. Hydrometer and<br />

sieve tests (ASTM D422) and Atterberg Limits tests (ASTM D43 18), were performed on samples of<br />

the soil taken immediately adjacent to the location of the Shelby tube samples. These index tests were<br />

per-formed at GCS's onsite soils laboratory.<br />

The specifications required a hydraulic conductivity less than or equal to I x 10w' cm/s. The<br />

hydraulic conductivity test results indicated that the permeabiliries of the Shelby tube samples ranged<br />

5 x 10' cm/s to 5 x 101 cm/s, with the exception of one Shelby tube sample taken in the southwest<br />

corner of the landfill that had a hydraulic conductivity of 1 x 101 cm/s. To determine the reason for<br />

the higher permeability of this sample, a test pit was excavated at the location at which the sample<br />

was obtained. The admix in the test pit contained lenses of sandy soil which likely caused the poor<br />

permeability test result. To determine the extent of the contaminated admix, four additional rest pits<br />

were excavated in the soil liner approximately 15 ft to the north, south, east, and west of the original<br />

test pit. No sandy lenses were observed in the additional test pits. Having bracketed the extent of the<br />

contaminated soil liner, all of the soil liner between the four additional test pits was reznoved and<br />

replaced with new admix material. Shelby tube samples were then taken in the replacement soil liner<br />

area, adjacent to the replacement area, and in the northwest corner of the landfill. The results of<br />

hydraulic conductivity tests on the three new Shelby tube samples indicated permeabilities that met the<br />

requirements of the specifications.<br />

The most likely reason for the contamination of the admix in the southwest corner of the<br />

landfill involved trucks hauling soil liner material to the floor of the landfill. At the time of the<br />

contamination, approximately three lifts of soil liner had been installed on the slopes and floor of the<br />

facility, but the access ramp had not been covered with soil liner. The ramp was left bare to enable<br />

easy access to the floor of the facility. Trucks hauling admix to the floor would travel down the bare<br />

access ramp and turn sharply into the southwest corner of the landfill. The trucks turned into the<br />

corner to enable them to back onto the floor of the facility to dump their loads of admix. The trucks<br />

likely tracked sand from the bare acces ramp onto the admix in the southwest corner of the landfill.<br />

933-1354 27

WHC-SD-W025-RPT-0O1, Rev. 0<br />

Following the completion of thie installation of the <strong>sec</strong>ondary soil liner, cold weather caused the<br />

top lift of the soil liner to freeze. Due to concerns that freezing and thawing could adversely affect<br />

the permeability of the soil liner, three Shelby tube samples were taken while the soil was frozen.<br />

Hydraulic conductivity tests were performed on the Shelby tube samples. The results of the tests<br />

indicated that the permeability of each sample met the requirements of the specifications. The<br />

locations of all Shelby tube samples taken in the <strong>sec</strong>ondary and primary soil liners are shown on<br />

Figure 7. After the soil liner thawed, and the muddy sheen on the surface of the soil liner was<br />

mechanically dried by the contractor, the installation of the <strong>sec</strong>ondary geomembrane liner was allowed<br />

to begin.<br />

With the exceptions noted above, all field and laboratory tests met the requirements of the<br />

specifications. Corrective measures were taken to rectify the noncompliances indicated by the failing<br />

tests. A summary of the field tests and laboratory tests performed on the <strong>sec</strong>ondary soil liner is<br />

presented in Table 14. The results of the laboratory tests are presented in Appendix D-4, and the<br />

results of the field moisture-density tests are presented in Appendix K-1.<br />

Table 14. Secondary Soil Liner Field and Laboratory Testing Summary.<br />

MINIUM TESTS I TESTS TESTS:<br />

FREQUENCY REQUIRED PERFORMED<br />

One Test Per Moisture-Density (ASTM D2922, 61 162<br />

250 yd' D30 17, D22 16, & D4643)_______<br />

One Test Per Hydraulic Conductivity 4 11<br />

5,000 yd' (ASTM D5084)<br />

None required<br />

Sieve and Hydrometer (ASTM D422) 0 12<br />

____________Atterberg Limits (ASTM D43 18) 0 11<br />

4.2 HDPE GEOM:EM[BRANE LINER INSTALLATION<br />

Material used in the construction of the Project W-025 Landfill <strong>sec</strong>ondary geomembrane liner<br />

consisted of 60-mil thick, smooth, HDPE geomembrane, and 60-mi! thick, textured, HDPE<br />

geornembrane. The smooth geornembrane was used on the floor of the facility, and the textured<br />

geomernbrane was used on the sideslopes and in the sump area of the facility. The HDPE liner<br />

material was manufactured by SLT North America, of Conroe, Texas.<br />

The geomemnbrane liner installer for this project was GeoPacific Lining Co. (GeoPacific) of<br />

Seattle, Washington. Installation of the <strong>sec</strong>ondary geosynthetic liner commenced on November 19,<br />

1993, and was completed on January 20, 1994. The installation of the geomernbrane started in the<br />

northeast corner of the landfill, and generally proceeded around the landfill in a counterclockwise<br />

direction.<br />

933-1354 28

WHC-SD-W025-RPT-01, Rev. 0<br />

4.2.1 KDPE Geornernbrane Liner Deployment<br />

Prior to deployment of the geoiernbrane liner, a panel layout drawing was submitted by<br />

GeoPacific showing the number and orientation of the various panels comprising the Project W-025<br />

Landfill geosynthetic liner. The HDPE liner was generally installed per the panel layout drawing<br />

with slight deviations to allow for correct joining of panels in the field. During deployment, GCS<br />

documented the as-built locations of the actual panels deployed. 'The approximate as-built<br />

geomembrane liner panel layouts are shown on Sheet S-1.<br />

Prior to deployment of the geomembrane liner, GCS and the installer observed the subgrade for<br />

conformance with the project specifications. A subgrade acceptance cerificate was issued and signed<br />

by the installer for each area where geornembrane was to be deployed. Copies of these subgrade<br />

acceptance certificates are presented in Appendix L.<br />

The rolls of geomeznbrane material were mounted on a spreader bar and deployed from the<br />

crests of the landfill's sideslopes. The geomembrane liner panels were deployed using either hand<br />

labor or a 4-wheel, all terrain vehicle (ATV). Both deployment methods minimized subgrade<br />

disturbance. During deployment of the geomembrane liner panels, the following services were<br />

provided by MC personnel:<br />

* Measurement of the panel thickness;<br />

* Confirmation of panel overlap;<br />

* Visual observation of overall sheet quality; and<br />

* Assignment of an unique identification number to each panel deployed.<br />

A nominal overlap of five inches was maintained between adjoining panels . The average<br />

thickness was determined by averaging ive measurements made along each of the leading edge,<br />

trailing edge, and one side of the panel. Approximately 187,700 square feet of <strong>sec</strong>ondary<br />

geornembrane liner were deployed. A summary of GCS' deployment observations is presented in<br />

Appendix M-1.<br />

-panel<br />

4.2.2 HDPE Geomembrane Liner Seaming<br />

Trial seams were made by each welding apparatus to be used and by each welding technician<br />

w ho was going to operate a welding apparatus (welder), at the start of each seaming period and at<br />

least once every four hours while seaming was being performed. Sample coupons were cut from each<br />

end of each trial seam and tested in the peel and shear test modes using a calibrated tensiometer<br />

supplied by CeoPacific. If a trial seam failed the field testing, the welder and welding apparatus<br />

associated with the failing trial seam were not allowed to weld on the geomembrane liner until a<br />

passing trial seam had been made in accordance with the specifications. A summary of the trial seam<br />

results is presented in Appendix M-2.<br />

The gornembrane liner panel seaming process Proceeded concurrently with the panel<br />

deployment. The majority of the seams were made using a double hot-wedge fusion welding<br />

apparatus. Repairs, corner seams, and some of the butt-seams between panels were made using an<br />

extrusion welding apparatus. The seaming operations were observed and documented by GCS<br />

personnel. The entire length of all seams, patches, or other repairs were observed and documented<br />

by GCS. A portion of the seaming was completed when the ambient temperature was less than 400<br />

Fahrenheit. The specifications required the installer to certify the quality of seams welded in ambient<br />

933-1354 29

WHC-SD-W025-RPT-001, Rev. 0<br />

temperatures less than 4Q0' Fahrenheit. GeoP acific certified that such seams were equivalent to seamns<br />

welded in temperatures ranging from 40r Fahrenheit to 1040 Fahrenheit. A copy of this certification<br />

is included in Appendix E-3. GCS also increased the frequency of destructive testing of seams<br />

welded at temperatures below 4Q0' Fahrenheit.<br />

Approximately 10, 103 feet of seams were welded on the <strong>sec</strong>ondary geomembrane l iner,<br />

including 9,366 feet of fusion welded seams and 737 feet of extrusion 'Welded seams. A summary of<br />

seaming operations is presented in Appendix M-3. The locations of the <strong>sec</strong>ondary geomernbrane liner<br />

seams are shown on Sheet S-1.<br />

4.2-3 Destructive Testing<br />

A total of 35 destructive test samples, excluding retests, were obtained from seams on the<br />