TeSys protection components - Trinet

TeSys protection components - Trinet

TeSys protection components - Trinet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

References<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole thermal overload relays, model d<br />

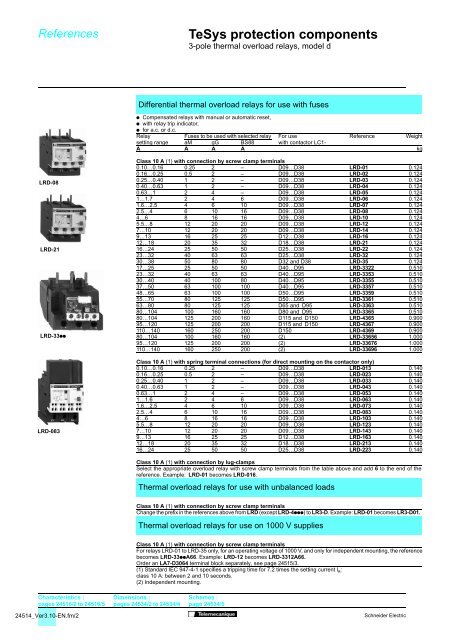

Differential thermal overload relays for use with fuses<br />

/ Compensated relays with manual or automatic reset,<br />

/ with relay trip indicator,<br />

/ for a.c. or d.c.<br />

Relay Fuses to be used with selected relay For use Reference Weight<br />

setting range aM gG BS88 with contactor LC1-<br />

A A A A kg<br />

LRD-08<br />

LRD-21<br />

LRD-33//<br />

LRD-083<br />

Class 10 A (1) with connection by screw clamp terminals<br />

0.10…0.16 0.25 2 – D09…D38 LRD-01 0.124<br />

0.16…0.25 0.5 2 – D09…D38 LRD-02 0.124<br />

0.25…0.40 1 2 – D09…D38 LRD-03 0.124<br />

0.40…0.63 1 2 – D09…D38 LRD-04 0.124<br />

0.63…1 2 4 – D09…D38 LRD-05 0.124<br />

1…1.7 2 4 6 D09…D38 LRD-06 0.124<br />

1.6…2.5 4 6 10 D09…D38 LRD-07 0.124<br />

2.5…4 6 10 16 D09…D38 LRD-08 0.124<br />

4…6 8 16 16 D09…D38 LRD-10 0.124<br />

5.5…8 12 20 20 D09…D38 LRD-12 0.124<br />

7…10 12 20 20 D09…D38 LRD-14 0.124<br />

9…13 16 25 25 D12…D38 LRD-16 0.124<br />

12…18 20 35 32 D18…D38 LRD-21 0.124<br />

16…24 25 50 50 D25…D38 LRD-22 0.124<br />

23…32 40 63 63 D25…D38 LRD-32 0.124<br />

30…38 50 80 80 D32 and D38 LRD-35 0.124<br />

17…25 25 50 50 D40…D95 LRD-3322 0.510<br />

23…32 40 63 63 D40…D95 LRD-3353 0.510<br />

30…40 40 100 80 D40…D95 LRD-3355 0.510<br />

37…50 63 100 100 D40…D95 LRD-3357 0.510<br />

48…65 63 100 100 D50…D95 LRD-3359 0.510<br />

55…70 80 125 125 D50…D95 LRD-3361 0.510<br />

63…80 80 125 125 D65 and D95 LRD-3363 0.510<br />

80…104 100 160 160 D80 and D95 LRD-3365 0.510<br />

80…104 125 200 160 D115 and D150 LRD-4365 0.900<br />

95…120 125 200 200 D115 and D150 LRD-4367 0.900<br />

110…140 160 250 200 D150 LRD-4369 0.900<br />

80…104 100 160 160 (2) LRD-33656 1.000<br />

95…120 125 200 200 (2) LRD-33676 1.000<br />

110…140 160 250 200 (2) LRD-33696 1.000<br />

Class 10 A (1) with spring terminal connections (for direct mounting on the contactor only)<br />

0.10…0.16 0.25 2 – D09…D38 LRD-013 0.140<br />

0.16…0.25 0.5 2 – D09…D38 LRD-023 0.140<br />

0.25…0.40 1 2 – D09…D38 LRD-033 0.140<br />

0.40…0.63 1 2 – D09…D38 LRD-043 0.140<br />

0.63…1 2 4 – D09…D38 LRD-053 0.140<br />

1…1.6 2 4 6 D09…D38 LRD-063 0.140<br />

1.6…2.5 4 6 10 D09…D38 LRD-073 0.140<br />

2.5…4 6 10 16 D09…D38 LRD-083 0.140<br />

4…6 8 16 16 D09…D38 LRD-103 0.140<br />

5.5…8 12 20 20 D09…D38 LRD-123 0.140<br />

7…10 12 20 20 D09…D38 LRD-143 0.140<br />

9…13 16 25 25 D12…D38 LRD-163 0.140<br />

12…18 20 35 32 D18…D38 LRD-213 0.140<br />

16…24 25 50 50 D25…D38 LRD-223 0.140<br />

Class 10 A (1) with connection by lug-clamps<br />

Select the appropriate overload relay with screw clamp terminals from the table above and add 6 to the end of the<br />

reference. Example: LRD-01 becomes LRD-016.<br />

Thermal overload relays for use with unbalanced loads<br />

Class 10 A (1) with connection by screw clamp terminals<br />

Change the prefix in the references above from LRD (except LRD-4///) to LR3-D. Example: LRD-01 becomes LR3-D01.<br />

Thermal overload relays for use on 1000 V supplies<br />

Class 10 A (1) with connection by screw clamp terminals<br />

For relays LRD-01 to LRD-35 only, for an operating voltage of 1000 V, and only for independent mounting, the reference<br />

becomes LRD-33//A66. Example: LRD-12 becomes LRD-3312A66.<br />

Order an LA7-D3064 terminal block separately, see page 24515/3.<br />

(1) Standard IEC 947-4-1 specifies a tripping time for 7.2 times the setting current I R<br />

:<br />

class 10 A: between 2 and 10 seconds.<br />

(2) Independent mounting.<br />

Characteristics :<br />

pages 24516/2 to 24516/5<br />

24514_Ver3.10-EN.fm/2<br />

Dimensions :<br />

pages 24534/2 to 24534/4<br />

Schemes :<br />

page 24534/5<br />

Schneider Electric

References<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole thermal overload relays, model d<br />

Differential thermal overload relays for use with fuses<br />

/ Compensated relays with manual or automatic reset,<br />

/ with relay trip indicator,<br />

/ for a.c. or d.c.<br />

/ LR2-D1508 to 2553: independent mounting<br />

- either by ordering a terminal block LA7-D1064 or LA7-D2064, see page 24515/3,<br />

- or by ordering the the relay pre-assembled; in this case add the suffix LA7 to the reference.<br />

Example: LR2-D1508 becomes LR2-D1508LA7.<br />

Relay Fuses to be used For use Reference Weight<br />

setting with the selected relay with contactor<br />

range aM gG BS88 LC1<br />

A A A A kg<br />

Class 20 (1) for connection by screw clamp terminals<br />

LRZ-D15//<br />

2.5…4 6 10 16 D09…D32 LR2-D1508 0.190<br />

4…6 8 16 16 D09…D32 LR2-D1510 0.190<br />

5.5…8 12 20 20 D09…D32 LR2-D1512 0.190<br />

7…10 16 20 25 D09…D32 LR2-D1514 0.190<br />

9…13 16 25 25 D12…D32 LR2-D1516 0.190<br />

12…18 25 35 40 D18…D32 LR2-D1521 0.190<br />

17…25 32 50 50 D25 and D32 LR2-D1522 0.190<br />

23…32 40 63 63 D25 and D32 LR2-D2553 0.345<br />

17…25 32 50 50 D40…D95 LR2-D3522 0.535<br />

23…32 40 63 63 D40…D95 LR2-D3553 0.535<br />

30…40 50 100 80 D40…D95 LR2-D3555 0.535<br />

37…50 63 100 100 D50…D95 LR2-D3557 0.535<br />

48…65 80 125 100 D50…D95 LR2-D3559 0.535<br />

55…70 100 125 125 D65…D95 LR2-D3561 0.535<br />

63…80 100 160 125 D80 and D95 LR2-D3563 0.535<br />

Electronic differential thermal overload relays for use with fuses<br />

LRZ-D25//<br />

/ Compensated relays,<br />

/ with relay trip indicator,<br />

/ for a.c. or d.c.,<br />

/ for direct mounting on contactor or independent mounting (2).<br />

Relay Fuses to be used For direct mounting Reference Weight<br />

setting with selected relay beneath contactor<br />

range aM gG LC1<br />

A A A kg<br />

Class 10 or 10A (1) with connection using bars or connectors<br />

60…100 100 160 D115 and D150 LR9-D5367 0.885<br />

90…150 160 250 D115 and D150 LR9-D5369 0.885<br />

Class 20 (3) with connection using bars or connectors<br />

60…100 125 160 D115 and D150 LR9-D5567 0.885<br />

90…150 200 250 D115 and D150 LR9-D5569 0.885<br />

Electronic thermal overload relays for use with balanced or unbalanced loads<br />

LRZ-D35//<br />

/ Compensated relays,<br />

/ with separate outputs for alarm and tripping.<br />

Relay Fuses to be used For direct mounting Reference Weight<br />

setting with the selected relay beneath contactor<br />

range aM gG LC1<br />

A A A kg<br />

Class 10 or 20 (1) selectable with connection using bars or connectors<br />

60…100 100 160 D115 and D150 LR9-D67 0.900<br />

90…150 160 250 D115 and D150 LR9-D69 0.900<br />

(1) Standard IEC 947-4-1 specifies a tripping time for 7.2 times the setting current I R<br />

class 10: between 4 and 10 seconds,<br />

class 10 A: between 2 and 10 seconds,<br />

class 20: between 6 and 20 seconds.<br />

(2) Power terminals can be protected against direct finger contact by the addition of shrouds and/or insulated terminal<br />

blocks, to be ordered separately (see page 24511/8).<br />

Characteristics :<br />

pages 24516/2 to 24516/5<br />

Other versions<br />

Dimensions :<br />

pages 24534/2 to 24534/4<br />

Thermal overload relays for resistive circuits in category AC-1.<br />

Please consult your Regional Sales Office.<br />

Schemes :<br />

page 24534/5<br />

Schneider Electric<br />

24514_Ver3.10-EN.fm/3

24515_Ver3.20-EN.fm/2<br />

Schneider Electric

References<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole thermal overload relays, model d<br />

Accessories (to be ordered separately)<br />

Description For Sold in Unit Weight<br />

use on lots of reference kg<br />

Pre-wiring kit allowing direct LC1-D09…D18 10 LAD-7C1 0.002<br />

connection of the N/C contact<br />

of relay LRD-01…35 or LC1-D25…D38 10 LAD-7C2 0.003<br />

LR3-D01…D35 to the contactor<br />

Terminal blocks (1) LRD-01…35 and LR3-D01…D35 1 LAD-7B10 0.100<br />

for clip-on mounting on 35 mm LR2-D15// 1 LA7-D1064 0.100<br />

rail (AM1-DP200) or screw LR2-D25// 1 LA7-D2064 0.120<br />

fixing; for fixing centres, see LRD-3///, LR3-D3///, 1 LA7-D3064 (2) 0.370<br />

pages 24534/2 to 24534/4 LR2-D35//<br />

Terminal block adapter LRD-3///, LR3-D3///, 1 LA7-D3058 0.080<br />

for mounting a relay<br />

LRD-35//<br />

beneath an LC1-D115 or D150<br />

contactor<br />

Mounting plates (3) LRD-01…35, LR3-D01…D35. 10 DX1-AP25 0.065<br />

for screw fixing<br />

LR2-D15//<br />

on 110 mm centres LR2-D25// 10 DX1-AP26 0.082<br />

LRD-3///, LR3-D3/// 1 LA7-D902 0.130<br />

LR2-D35//<br />

LAD-7C/<br />

Marker holder All relays except LRD-01…35 100 LA7-D903 0.001<br />

snap in and LR3-D01…D35 (4)<br />

Bag of 400 labels – 1 LA9-D91 0.001<br />

(blank, self-adhesive, 7 x 16 mm)<br />

Stop button locking device All relays except LRD-01…35. 10 LA7-D901 0.005<br />

LR3-D01…D35 and LR9-D<br />

Remote stop or electrical LRD-01…35 and LR3-D01…D35 1 LAD-703/ (6) 0.090<br />

reset device (5)<br />

Remote tripping or electrical All relays except LRD-01…35 1 LA7-D03/(6) 0.090<br />

reset device (5)<br />

and LR3-D01…D35<br />

Block of insulated terminals LR9-D 2 LA9-F103 0.560<br />

Remote control<br />

“Reset” function<br />

By flexible cable LRD-01…35 and LR3-D01…D35 1 LAD-7305 0.075<br />

(length = 0.5 m) All relays except LRD-01…35 1 LA7-D305 0.075<br />

and LR3-D01…D35<br />

LAD-7B10<br />

“Stop” and/or “Reset” functions<br />

The terminal <strong>protection</strong> shroud must be removed and the following 3 products must be ordered separately.<br />

Adapter All relays except LRD-01…35 1 LA7-D1020 0.005<br />

for door interlock mechanism and LR3-D01…D35<br />

Illustrations :<br />

page 24515/2<br />

Schneider Electric<br />

Operating head Stop All relays 1 XB5-AL84101 0.027<br />

for spring return pushbutton Reset All relays 1 XB5-AA86102 0.027<br />

(1) Terminal blocks are supplied with terminals protected against direct finger contact and screws in the open, “readyto-tighten”<br />

position.<br />

(2) To order a terminal block for connection by lugs, the reference becomes LA7-D30646.<br />

(3) Do not forget to order the terminal block corresponding to the type of relay.<br />

(4) For LRD-01…35, see page 24511/9.<br />

(5) The time for which the coil of remote tripping or electrical resetting device LA7-D03 or LAD-703 can remain energised<br />

depends on its rest time: 1 s pulse duration with 9 s rest time; 5 s pulse duration with 30 s rest time; 10 s pulse duration<br />

with 90 s rest time; maximum pulse duration of 20 s with a rest time of 300 s. Minimum pulse time: 200 ms.<br />

(6) Reference to be completed by adding the code indicating control circuit voltage.<br />

Standard control circuit voltages (for other voltages, please consult your Regional Sales Office)<br />

Volts 12 24 48 96 110 220/230 380/400 415/440<br />

50/60 Hz – B E – F M Q N<br />

Consumption, inrush and sealed: < 100 VA<br />

$ J B E DD F M – –<br />

Consumption, inrush and sealed: < 100 W.<br />

Dimensions :<br />

pages 24534/2 to 24534/4<br />

24515_Ver3.20-EN.fm/3

Description,<br />

characteristics<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole thermal overload relays, model d<br />

Description<br />

Model d 3-pole thermal overload relays are designed to protect a.c. circuits and motors against overloads, phase failure,<br />

long starting times and prolonged stalling of the motor.<br />

LRD-01…35<br />

5<br />

3<br />

3,5 0 1<br />

4<br />

RESET<br />

STOP<br />

1<br />

6<br />

2 & 5<br />

4<br />

3<br />

2<br />

6<br />

LRD-3322…4369, LR2-D<br />

7<br />

NO<br />

NC<br />

98 97 95 96<br />

1 Adjustment dial Ir<br />

2 Test button<br />

Operation of the Test button allows:<br />

- checking of control circuit wiring,<br />

- simulation of relay tripping (actuates both the N/O and N/C contacts).<br />

3 Stop button. Actuates the N/C contact; does not affect the N/O contact.<br />

4 Reset button<br />

5 Trip indicator<br />

6 Setting locked by sealing the cover.<br />

7 Selector for manual or automatic reset. Relays LRD-01 to 35 are supplied with the selector in the manual position,<br />

protected by a cover. Deliberate action is required to move it to the automatic position.<br />

41<br />

37<br />

TEST<br />

46<br />

50<br />

A<br />

M<br />

R<br />

A E<br />

S<br />

E<br />

T<br />

1<br />

5<br />

3<br />

4<br />

Environment<br />

Conforming to standards IEC 947-1, IEC 947-4-1, NF C 63-650, VDE 0660,<br />

BS 4941<br />

Product certifications<br />

CSA, UL, Sichere Trennung, PTB except LAD-4:<br />

UL, CSA.<br />

Degree of <strong>protection</strong> Conforming to VDE 0106 Protection against direct finger contact IP 2X<br />

Protective treatment Conforming to IEC 68 “TH”<br />

Ambient air temperature Storage °C - 60…+ 70<br />

around the device Normal operation, without derating (IEC 947-4-1) °C - 20…+ 60<br />

Minimum and maximum operating temperatures °C - 40…+ 70<br />

(with derating)<br />

Operating positions In relation to normal, vertical mounting plane Any position<br />

without derating<br />

Shock resistance Permissible acceleration conforming to IEC 68-2-7 15 gn - 11 ms<br />

Vibration resistance Permissible acceleration conforming to IEC 68-2-6 6 gn<br />

Dielectric strength at 50 Hz Conforming to IEC 255-5 kV 6<br />

Impulse withstand voltage Conforming to IEC 801-5 kV 6<br />

Auxiliary contact characteristics<br />

Conventional thermal current A 5<br />

Maximum consumption a.c. supply V 24 48 110 220 380 600<br />

of operating coils VA 100 200 400 600 600 600<br />

of controlled contactors<br />

(Occasional operating d.c. supply V 24 48 110 220 440 –<br />

cycles of contact 95-96) W 100 100 50 45 25 –<br />

Short-circuit <strong>protection</strong> By gG or BS fuse. Max. rating or by GB2 circuit-breaker A 5<br />

Connection to screw clamp terminals<br />

Min/max c.s.a.<br />

Flexible cable without cable end 1 or 2 conductors mm2 1/2.5<br />

Flexible cable with cable end 1 or 2 conductors mm2 1/2.5<br />

Solid cable without cable end 1 or 2 conductors mm2 1/2.5<br />

Tightening torque N.m 1.7<br />

Connection to spring terminals<br />

Min/max c.s.a.<br />

Flexible cable without cable end 1 or 2 conductors mm2 1/2.5<br />

Solid cable without cable end 1 or 2 conductors mm2 1/2.5<br />

References:<br />

pages 24514/2 and<br />

24514/3<br />

Dimensions:<br />

pages 24534/2 to 24534/<br />

4<br />

Schemes:<br />

page 24534/5<br />

24516_Ver2.30-EN.fm/2<br />

Schneider Electric

Characteristics<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole thermal overload relays, model d<br />

Electrical characteristics of power circuit<br />

Relay type<br />

LRD-<br />

01 to 16<br />

LR3-<br />

D01 to D16<br />

LR2-<br />

D15//<br />

LRD-<br />

21 to 35<br />

LR3-<br />

D21 to D35<br />

LR2-<br />

D25//<br />

LRD-<br />

3322 to<br />

33696<br />

LR3-<br />

D3322 to<br />

D33696<br />

LR2-<br />

D35//<br />

LRD-<br />

4365 to<br />

4369<br />

Tripping class To UL 508, IEC 947-4-1 10 A 20 10 A 20 10 A 20 10 A<br />

V<br />

Rated insulation voltage (Ui) Conforming to IEC 947-4-1<br />

690 690 1000 1000<br />

Conforming to UL, CSA V 600 600 600 600 except<br />

LRD-4369<br />

Rated impulse withstand<br />

voltage (Uimp) kV 6 6 6 6<br />

Frequency limits Of the operational current Hz 0…400 0…400 0…400 0…400<br />

Setting range Depending on model A 0.1…13 12…38 17…104 80…140<br />

Connection to screw clamp terminals<br />

Min/max c.s.a.<br />

Flexible cable without cable end 1 conductor mm2 1.5/10 1.5/10 4/35 4/50<br />

Flexible cable with cable end 1 conductor mm2 1/4 1/6 except<br />

LRD-21: 1/4<br />

Solid cable without cable end 1 conductor mm2 1/6 1.5/10 except<br />

LRD-21: 1/6<br />

4/35 4/35<br />

4/35 4/50<br />

Tightening torque N.m 1.7 1.85 2.5 9 9<br />

Connection to spring terminals<br />

Min/max c.s.a.<br />

Flexible cable without cable end 1 conductor mm2 1.5/4 – 1.5/4 – – – –<br />

Solid cable without cable end 1 conductor mm 2 1.5/4 – 1.5/4 – – – –<br />

Operating characteristics<br />

Temperature compensation °C - 20…+ 60 - 30…+ 60- - 30…+ 60 - 20…+ 60<br />

Tripping threshold Conforming to IEC 947-4-1 A 1.14 ± 0.06 In<br />

Sensitivity to phase failure Conforming to IEC 947-4-1 Tripping current 30 % of In on one phase, the others at In<br />

Tripping curves<br />

Average operating time<br />

related to multiples of the<br />

current setting<br />

Seconds Minutes<br />

Hours<br />

2<br />

1<br />

40<br />

20<br />

10<br />

4<br />

2<br />

1<br />

40<br />

20<br />

10<br />

Time<br />

class 10 A<br />

4<br />

1<br />

2<br />

2<br />

3<br />

1<br />

0,8<br />

0,8 1 2 4 6 10 17 20<br />

x current setting (Ir)<br />

Seconds Minutes Hours<br />

2<br />

1<br />

40<br />

20<br />

10<br />

1 Balanced operation, 3-phase, from cold state.<br />

2 Balanced operation, 2-phase, from cold state.<br />

3 Balanced operation, 3-phase, after a long period at the set current (hot state).<br />

Time<br />

class 20<br />

4<br />

2<br />

1<br />

40<br />

20<br />

10<br />

1<br />

4<br />

2<br />

3<br />

2<br />

1<br />

0,8<br />

0,8 1 2 4 6 10 17 20<br />

x current setting (Ir)<br />

References:<br />

pages 24514/2 and<br />

24514/3<br />

Dimensions:<br />

pages 24534/2 to 24534/<br />

4<br />

Schemes:<br />

page 24534/5<br />

Schneider Electric<br />

24516_Ver2.30-EN.fm/3

Description,<br />

characteristics<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole electronic thermal overload relays LR9-D<br />

Description<br />

LR9-D electronic thermal overload relays are designed for use with contactors LC1-D115 and D150.<br />

In addition to the <strong>protection</strong> provided by model d thermal overload relays (see page 24516/2) they offer the following<br />

special features:<br />

/ Protection against phase imbalance.<br />

/ Choice of starting class.<br />

/ Protection of unbalanced circuits.<br />

/ Protection of single-phase circuits.<br />

/ Alarm function to avoid tripping by load shedding.<br />

1 Setting dial Ir<br />

2 Test button<br />

3 Stop button<br />

4 Reset button<br />

5 Trip indication<br />

6 Setting locked by sealing the cover<br />

7 Class 10/class 20 selector<br />

8 Selector for balanced load /<br />

unbalanced load<br />

LR9-D5367…D5569<br />

Ir(A)<br />

107 127<br />

90 150<br />

NO 98 97<br />

NC<br />

95 96<br />

1<br />

2<br />

5<br />

4<br />

3<br />

6<br />

LR9-D67 and D69<br />

Class Load<br />

Ir(A) 20<br />

107 127<br />

10<br />

+ 24 V - / 103 104<br />

90 150<br />

Alarm<br />

NO 98 97<br />

NC<br />

95 96<br />

7<br />

8<br />

2<br />

5<br />

4<br />

3<br />

1<br />

6<br />

Environment<br />

Conforming to standards IEC 947-4-1, 255-8, 255-17, VDE 0660 and EN 60947-4-1<br />

Product certifications UL 508 , CSA 22-2<br />

Degree of <strong>protection</strong> Conforming to IEC 529 and VDE 0106 IP 20 on front face<br />

with protective covers LA9-D11570/ or D11560/<br />

Protective treatment Standard version "TH"<br />

Ambient air temperature Storage °C - 40…+ 85<br />

around the device<br />

(conforming to IEC 255-8)<br />

Normal operation °C - 20…+ 55 (1)<br />

Maximum operating altitude Without derating m 2000<br />

Operating positions<br />

In relation to normal, vertical<br />

without derating<br />

mounting plane<br />

Any position<br />

Shock resistance<br />

Permissible acceleration<br />

13 gn - 11 ms<br />

conforming to IEC 68-2-27<br />

Vibration resistance<br />

Permissible acceleration<br />

conforming to IEC 68-2-6<br />

2 gn - 5 to 300 Hz<br />

Dielectric strength at 50 Hz Conforming to IEC 255-5 kV 6<br />

Impulse withstand voltage Conforming to IEC 1000-4-5 kV 6<br />

Resistance to electrostatic discharge Conforming to IEC 1000-4-2 kV 8<br />

Resistance to radio-frequency Conforming to IEC 1000-4-3<br />

conducted disturbances<br />

and NF C 46-022<br />

V/m 10<br />

Resistance to fast transient currents Conforming to IEC 1000-4-4 kV 2<br />

Electromagnetic compatibility Draft EN 50081-1 and 2, EN 50082-2 Meets requirements<br />

Electrical characteristics of auxiliary contacts<br />

Conventional thermal current A 5<br />

Maximum consumption a.c. supply V 24 48 110 220 380 600<br />

of operating coils VA 100 200 400 600 600 600<br />

of controlled contactors<br />

(Occasional operating cycles<br />

d.c. supply V 24 48 110 220 440 –<br />

of contact 95-96) W 100 100 50 45 25 –<br />

Short-circuit <strong>protection</strong><br />

By gG or BS fuse<br />

or by GB2 circuit-breaker<br />

A 5<br />

Cabling 1 or 2 conductors mm2 Minimum c.s.a.: 1/maximum c.s.a.: 2.5<br />

Flexible cable without cable end Tightening torque N.m 1.2<br />

(1) For operation at 70 °C, please consult your Regional Sales Office.<br />

References:<br />

pages 24514/2 and<br />

24516_Ver2.30-EN.fm/4<br />

24514/3<br />

Dimensions:<br />

pages 24534/2 to 24534/<br />

4<br />

Schemes:<br />

page 24534/5<br />

Schneider Electric

Characteristics<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

6<br />

3-pole electronic thermal overload relays LR9-D<br />

Electrical characteristics of power circuit<br />

Relay type<br />

LR9-D<br />

Tripping class Conforming to UL 508, IEC 947-4-1 10 A or 20<br />

Rated insulation voltage (Ui) Conforming to IEC 947-4-1 V 1000<br />

Conforming to UL, CSA V 600<br />

Rated impulse withstand<br />

voltage (Uimp)<br />

kV 8<br />

Frequency limits Of the operational current Hz 50…60. For other frequencies, consult your Regional Sales Office (1)<br />

Setting range Depending on model A 60…150<br />

Power circuit connections Width of terminal lug mm 20<br />

Clamping screw<br />

M8<br />

Tightening torque N.m 18<br />

Operating characteristics<br />

Temperature compensation °C - 20…+ 70<br />

Tripping thresholds To IEC 947-4-1 Alarm A 1.05 ± 0.06 In<br />

Tripping A 1.12 ± 0.06 In<br />

Sensitivity to phase failure Conforming to IEC 947-4-1 Tripping in 4 s ± 20 % in the event of phase failure<br />

Alarm circuit characteristics<br />

Rated supply voltage d.c. supply V 24<br />

Supply voltage limits V 17…32<br />

Current consumption No load mA ≤ 5<br />

Switching capacity mA 0…150<br />

Protection Short-circuit and overload Self-protected<br />

Voltage drop Closed state V ≤ 2.5<br />

Cabling Flexible cable without cable end mm2 0.5…1.5<br />

Tightening torque N.m 0.45<br />

Tripping curve LR9-D<br />

Average operating time<br />

related to multiples of the<br />

current setting<br />

Tripping time in seconds<br />

000<br />

100<br />

10<br />

1<br />

2<br />

1<br />

0 1 1,12 2 3 4 5 6 7 8 9 10 11 12<br />

x the current setting (Ir)<br />

1 Cold state curve<br />

2 Hot state curve<br />

(1) For use of these relays with soft start units or variable speed controllers, please consult your Regional Sales Office.<br />

References:<br />

pages 24514/2 and<br />

24514/3<br />

Dimensions:<br />

pages 24534/2 to 24534/<br />

4<br />

Schemes:<br />

page 24534/5<br />

Schneider Electric<br />

24516_Ver2.30-EN.fm/5

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit breakers types GV2-ME<br />

and GV2-P<br />

Thermal-magnetic tripping curves for GV2-ME and GV2-P<br />

Average operating time at 20 °C according to multiples of the setting current<br />

Time (s)<br />

x setting current (Ir)<br />

1 3 poles from cold state<br />

2 2 poles from cold state<br />

3 3 poles from hot state<br />

References :<br />

pages 24508/2 to 24508/4<br />

Dimensions :<br />

pages 24538/2 to 24538/4<br />

Schemes :<br />

page 24538/8<br />

4521 Ver2.00-EN.fm/2 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers types GV2-ME<br />

and GV2-P<br />

Current limitation on short-circuit for GV2-ME and GV2-P<br />

3-phase 400/415 V<br />

Dynamic stress<br />

I peak = f (prospective Isc) at 1.05 Ue = 435 V<br />

Limited peak current (kA)<br />

Prospective Isc (kA)<br />

1 Maximum peak current 7 6-10 A<br />

2 24-32 A 8 4-6.3 A<br />

3 20-25 A 9 2.5-4 A<br />

4 17-23 A 10 1.6-2.5 A<br />

5 13-18 A 11 1-1.6 A<br />

6 9-14 A 12 Limit of rated ultimate breaking capacity on short-circuit<br />

of GV2-ME (14, 18, 23 and 25 A ratings)<br />

References :<br />

pages 24508/2 to 24508/4<br />

Dimensions :<br />

pages 24538/2 to 24538/4<br />

Schemes :<br />

page 24538/8<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers types GV2-ME<br />

and GV2-P<br />

Thermal limit on short-circuit for GV2-ME<br />

Thermal limit in KA 2 s in the magnetic operating zone<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (kA 2 s)<br />

Prospective Isc (kA)<br />

1 24-32 A 6 6-10 A<br />

2 20-25 A 7 4-6.3 A<br />

3 17-23 A 8 2.5-4 A<br />

4 13-18 A 9 1.6-2.5 A<br />

5 9-14 A 10 1-1.6 A<br />

References :<br />

pages 24508/2 to 24508/4<br />

Dimensions :<br />

pages 24538/2 to 24538/4<br />

Schemes :<br />

page 24538/8<br />

4521 Ver2.00-EN.fm/4 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers types GV2-ME<br />

and GV2-P<br />

Thermal limit on short-circuit for GV2-P<br />

Thermal limit in kA 2 s in the magnetic operating zone<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (kA 2 s)<br />

Prospective Isc (kA)<br />

1 24-32 A 6 6-10 A<br />

2 20-25 A 7 4-6.3 A<br />

3 17-23 A 8 2.5-4 A<br />

4 13-18 A 9 1.6-2.5 A<br />

5 9-14 A 10 1-1.6 A<br />

References :<br />

pages 24508/2 to 24508/4<br />

Dimensions :<br />

pages 24538/2 to 24538/4<br />

Schemes :<br />

page 24538/8<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV3-ME<br />

Thermal-magnetic tripping curves<br />

Average operating time at 20 °C according to multiples of the setting current.<br />

Time (s)<br />

X setting current (Ir)<br />

1 3 poles from cold state, 1.6…16 A rating<br />

2 3 poles from hot state , 1.6…16 A rating<br />

3 3 poles from cold state, 25…80 A rating<br />

4 3 poles from hot state, 25…80 A rating<br />

References :<br />

page 24508/5<br />

Dimensions :<br />

page 24538/5<br />

Schemes :<br />

page 24538/9<br />

4521 Ver2.00-EN.fm/6 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV3-ME<br />

Current limitation on short-circuit<br />

3-phase 400/415 V.<br />

Dynamic stress<br />

I peak = f (prospective Isc) at 1.05 Ue = 435 V<br />

Limited peak current (kA)<br />

Prospective Isc (kA)<br />

1 Maximum peak current 7 6…10 A<br />

2 56…80 A 8 4…6 A<br />

3 40…63 A 9 2.5…4 A<br />

4 25…40 A 10 1.6…2.5 A<br />

5 16…25 A 11 1…1.6 A<br />

6 10…16 A<br />

References :<br />

page 24508/5<br />

Dimensions :<br />

page 24538/5<br />

Schemes :<br />

page 24538/9<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV3-ME<br />

Thermal limit on short-circuit<br />

Thermal limit in kA 2 s in the magnetic operating zone<br />

Sum of l 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (kA 2 s)<br />

Prospective Isc (kA)<br />

1 56…80 A 6 6…10 A<br />

2 40…63 A 7 4…6 A<br />

3 25…40 A 8 2.5…4 A<br />

4 16…25 A 9 1.6…2.5 A<br />

5 10…16 A<br />

References :<br />

page 24508/5<br />

Dimensions :<br />

page 24538/5<br />

Schemes :<br />

page 24538/9<br />

4521 Ver2.00-EN.fm/8 Schneider Electric

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV7-R<br />

Thermal-magnetic tripping curves for GV7-R<br />

Average operating time at 20 °C according to multiples of the setting current<br />

Time (s)<br />

x setting current (Ir)<br />

1 Curve from cold state<br />

2 Curve from hot state<br />

3 12…14 Ir<br />

In the event of total phase failure, tripping occurs after 4 s ± 20 %<br />

References :<br />

page 24508/6<br />

Dimensions :<br />

pages 24538/5 to 24538/7<br />

Schemes :<br />

page 24538/9<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV7-R<br />

Current limitation on short-circuit<br />

3-phase 400/415 V<br />

Dynamic stress<br />

I peak = f (prospective Isc)<br />

For GV7-RE only<br />

Limited peak current (kA)<br />

1 GV7-RE220<br />

2 GV7-RE150<br />

3 GV7-RE100<br />

Prospective Isc (kA)<br />

For GV7-RS only<br />

Limited peak current (kA)<br />

1 GV7-RS220<br />

2 GV7-RS150<br />

3 GV7-RS100<br />

Prospective Isc (kA)<br />

References :<br />

page 24508/6<br />

Dimensions :<br />

pages 24538/5 to 24538/7<br />

Schemes :<br />

page 24538/9<br />

521 Ver2.00-EN.fm/10 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV7-R<br />

Thermal limit on short-circuit<br />

3-phase 400/415 V<br />

Thermal limit<br />

Sum of I 2 dt = f (prospective Isc)<br />

For GV7-RE only<br />

Sum of I 2 dt (A 2 s)<br />

1 GV7-RE220<br />

2 GV7-RE150<br />

3 GV7-RE100<br />

Prospective Isc (kA)<br />

For GV7-RS only<br />

Sum of I 2 dt (A 2 s)<br />

1 GV7-RS220<br />

2 GV7-RS150<br />

3 GV7-RS100<br />

Prospective Isc (kA)<br />

References :<br />

page 24508/6<br />

Dimensions :<br />

pages 24538/5 to 24538/7<br />

Schemes :<br />

page 24538/9<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV7-R<br />

Current limitation on short-circuit<br />

3-phase 690 V<br />

Dynamic stress<br />

I peak = f (prospective Isc)<br />

For GV7-RE only<br />

Limited peak current (kA)<br />

1 GV7-RE220<br />

2 GV7-RE150 and<br />

GV7-RE100<br />

Prospective Isc (kA)<br />

For GV7-RS only<br />

Limited peak current (kA)<br />

1 GV7-RS220<br />

2 GV7-RS150 and<br />

GV7-RS100<br />

Prospective Isc (kA)<br />

References :<br />

page 24508/6<br />

Dimensions :<br />

pages 24538/5 to 24538/7<br />

Schemes :<br />

page 24538/9<br />

521 Ver2.00-EN.fm/12 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV7-R<br />

Thermal limit on short-circuit<br />

3-phase 690 V<br />

Thermal limit<br />

Sum of I 2 dt = f (prospective Isc)<br />

For GV7-RE only<br />

Sum of I 2 dt (A 2 s)<br />

1 GV7-RE220<br />

2 GV7-RE150 and<br />

GV7-RS100<br />

Prospective Isc (kA)<br />

For GV7-RS only<br />

Sum of I 2 dt (A 2 s)<br />

1 GV7-RS220<br />

2 GV7-RS150 and<br />

GV7-RS100<br />

Prospective Isc (kA)<br />

References :<br />

page 24508/6<br />

Dimensions :<br />

pages 24538/5 to 24538/7<br />

Schemes :<br />

page 24538/9<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Thermal-magnetic motor circuit-breakers type GV2-RT<br />

Thermal-magnetic tripping curves for GV2-RT<br />

Time (s)<br />

1 3 poles from cold state<br />

2 2 poles from cold state<br />

3 3 poles from hot state<br />

References :<br />

page 24508/7<br />

Dimensions :<br />

page 24538/4<br />

Schemes :<br />

page 24538/8<br />

521 Ver2.00-EN.fm/14 Schneider Electric

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Tripping curves for GV2-L or LE combined with thermal overload relay LRD or LR2-K<br />

Average operating time at 20°C according to multiples of the setting current<br />

Time (s)<br />

x setting current (Ir)<br />

1 3 poles from cold state<br />

2 2 poles from cold state<br />

3 3 poles from hot state<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Current limitation on short-circuit<br />

For GV2-L and GV2-LE only<br />

3-phase 400/415 V<br />

Dynamic stress<br />

I peak = f (prospective Isc) at 1.05 Ue = 435 V<br />

Limited peak current (kA)<br />

Prospective Isc (kA)<br />

1 Maximum peak current 6 10 A.<br />

2 32 A 7 6.3 A<br />

3 25 A 8 4 A<br />

4 18 A 9 2.5 A<br />

5 14 A 10 1.6 A<br />

11 Limit of rated ultimate breaking capacity on short-circuit of GV2-LE<br />

(14, 18 and 25 A ratings)<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

521 Ver2.00-EN.fm/16 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Current limitation on short-circuit<br />

For GV2-L and GV2-LE + thermal overload relay LRD or LR2-K<br />

3-phase 400/415 V<br />

Dynamic stress<br />

I peak = f (prospective Isc) at 1.05 Ue = 435 V<br />

Limited peak current (kA)<br />

Prospective Isc (kA)<br />

1 Maximum peak current 6 10 A<br />

2 32 A 7 6.3 A<br />

3 25 A 8 4 A<br />

4 18 A 9 2.5 A<br />

5 14 A 10 1.6 A<br />

11 Limit of rated ultimate breaking capacity on short-circuit<br />

of GV2-LE (14, 18 and 25 A ratings)<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Thermal limit on short-circuit for GV2-LE only<br />

Thermal limit in kA 2 s in the magnetic operating zone<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (kA 2 s)<br />

Prospective Isc (kA)<br />

1 32 A 6 6.3 A<br />

2 25 A 7 4 A<br />

3 18 A 8 2.5 A<br />

4 14 A 9 1.6 A<br />

5 10 A<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

521 Ver2.00-EN.fm/18 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Thermal limit on short-circuit for GV2-L only<br />

Thermal limit in kA 2 s in the magnetic operating zone<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (kA 2 s)<br />

1 25 A and 32 A 5 6.3 A<br />

2 18 A 6 4 A<br />

3 14 A 7 2.5 A<br />

4 10 A 8 1.6 A<br />

Prospective Isc (kA)<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breakers types GV2-L and GV2-LE<br />

Thermal limit on short-circuit<br />

For GV2-L and GV2-LE + thermal overload relay LRD or LR2-K<br />

Thermal limit in kA 2 s in the magnetic operating zone<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I2dt (kA2 s)<br />

Prospective Isc (kA)<br />

1 32 A (GV2-LE32) 7 4 A<br />

2 25 A and 32 A (GV2-L32) 8 2.5 A<br />

3 18 A 9 1.6 A<br />

4 14 A 10 Limit of rated ultimate breaking capacity on short-circuit<br />

5 10 A of GV2-LE (14, 18 and 25 A ratings)<br />

6 6.3 A<br />

References :<br />

page 24522/2<br />

Dimensions :<br />

pages 24527/2 to 24527/4<br />

Schemes :<br />

page 24527/5<br />

521 Ver2.00-EN.fm/20 Schneider Electric

Curves<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breaker type GK3<br />

Tripping curves for GK3 combined with thermal overload relay LRD-33<br />

Average operating time at 20 °C without prior current flow.<br />

Time (s)<br />

x setting current (Ir)<br />

1 3 poles from cold state<br />

2 2 poles from cold state<br />

3 3 poles from hot state<br />

A Thermal overload relay <strong>protection</strong> zone<br />

B GK3 <strong>protection</strong> zone<br />

References :<br />

page 24522/3<br />

Dimensions :<br />

page 24527/4<br />

Schemes :<br />

page 24527/5<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/2

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breaker type GK3<br />

Current limitation on short-circuit for GK3 only<br />

3-phase 400/415 V<br />

Dynamic stress<br />

I peak = f (prospective Isc) at 1.05 Ue = 435 V<br />

Limited peak current (kA)<br />

1 Maximum peak current<br />

2 80 A<br />

3 65 A<br />

4 40 A<br />

Prospective Isc (kA)<br />

References :<br />

page 24522/3<br />

Dimensions :<br />

page 24527/4<br />

Schemes :<br />

page 24527/5<br />

521 Ver2.00-EN.fm/22 Schneider Electric

Curves (continued)<br />

<strong>TeSys</strong> <strong>protection</strong> <strong>components</strong><br />

Magnetic motor circuit-breaker type GK3<br />

Thermal limit on short-circuit for GK3 only<br />

Thermal limit in A 2 s<br />

Sum of I 2 dt = f (prospective Isc) at 1.05 Ue = 435 V<br />

Sum of I 2 dt (A 2 s)<br />

Prospective Isc (kA)<br />

1 80 A<br />

2 65 A<br />

3 40 A<br />

References :<br />

page 24522/3<br />

Dimensions :<br />

page 24527/4<br />

Schemes :<br />

page 24527/5<br />

Schneider Electric<br />

24521 Ver2.00-EN.fm/2

Selection guide<br />

<strong>TeSys</strong> contactors<br />

For utilisation category AC-3<br />

Operational current and power conforming to IEC (θ ≤ 60 °C)<br />

Contactor LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

size LP1- LP1- LP1-<br />

K06 K09 K12 K16 D09 D12 D18 D25 D32 D38 D40<br />

Max. operational ≤ 440 V A 6 9 12 16 9 12 18 25 32 38 40<br />

current in AC-3<br />

Rated 220/240 V kW 1.5 2.2 3 3 2.2 3 4 5.5 7.5 9 11<br />

operational<br />

power P<br />

(standard 380/400 V kW 2.2 4 5.5 7.5 4 5.5 7.5 11 15 18.5 18.5<br />

motor power<br />

ratings)<br />

415 V kW 2.2 4 5.5 7.5 4 5.5 9 11 15 18.5 22<br />

440 V kW 3 4 5.5 7.5 4 5.5 9 11 15 18.5 22<br />

500 V kW 3 4 4 5.5 5.5 7.5 10 15 18.5 18.5 22<br />

660/690 V kW 3 4 4 4 5.5 7.5 10 15 18.5 18.5 30<br />

1000 V kW – – – – – – – – – – 22<br />

Maximum operating rate in operating cycles/hour (1)<br />

On-load Operational LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

factor<br />

power<br />

D09 D12 D18 D25 D32 D38 D40<br />

≤ 85% P – – – – 1200 1200 1200 1200 1000 1000 1000<br />

0.5 P – – – – 3000 3000 2500 2500 2500 2500 2500<br />

≤ 25 % P – – – – 1800 1800 1800 1800 1200 1200 1200<br />

Operational current and power conforming to UL, CSA (θ ≤ 60 °C)<br />

Contactor LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

size LP1- LP1- LP1-<br />

K06 K09 K12 D09 D12 D18 D25 D32 D38 D40<br />

Max. operational ≤ 440 V A 6 9 12 9 12 18 25 32 – 40<br />

current in AC-3<br />

Rated 200/208 V HP 1.5 2 3 2 3 5 7.5 10 – 10<br />

operational<br />

power P<br />

(standard 230/240 V HP 1.5 3 3 2 3 5 7.5 10 – 10<br />

motor power<br />

ratings)<br />

60 Hz 460/480 V HP 3 5 7.5 5 7.5 10 15 20 – 30<br />

575/600 V HP 3 5 10 7.5 10 15 20 25 – 30<br />

(1) Depending on the operational power and the on-load factor (θ ≤ 60 °C).<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

2<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

50 65 80 95 115 150 185 225 265 330 400 500 630 780 800 750 1000 1500 1800<br />

15 18.5 22 25 30 40 55 63 75 100 110 147 200 220 250 220 280 425 500<br />

22 30 37 45 55 75 90 110 132 160 200 250 335 400 450 400 500 750 900<br />

25 37 45 45 59 80 100 110 140 180 220 280 375 425 450 425 530 800 900<br />

30 37 45 45 59 80 100 110 140 200 250 295 400 425 450 450 560 800 900<br />

30 37 55 55 75 90 110 129 160 200 257 355 400 450 450 500 600 750 900<br />

33 37 45 45 80 100 110 129 160 220 280 335 450 475 475 560 670 750 900<br />

30 37 45 45 65 75 100 100 147 160 185 335 450 450 450 530 530 670 750<br />

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

1000 1000 750 750 750 750 750 750 750 750 500 500 500 500 500 120 120 120 120<br />

2500 2500 2000 2000 2000 1200 2000 2000 2000 2000 1200 1200 1200 1200 600 120 120 120 120<br />

1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 1200 600 600 120 120 120 120<br />

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800<br />

50 65 80 95 115 150 185 225 265 330 400 500 630 780 800<br />

15 20 30 30 30 40 50 60 60 75 100 150 250 – 350<br />

15 20 30 30 40 50 60 75 75 100 125 200 300 450 400<br />

40 50 60 60 75 100 125 150 150 200 250 400 600 900 900<br />

40 50 60 60 100 125 150 150 200 250 300 500 800 – 900

Selection guide according<br />

to required electrical<br />

durability<br />

<strong>TeSys</strong> contactors<br />

For utilisation category AC-3<br />

Use in category AC-3 (Ue ≤ 440 V)<br />

Control of 3-phase<br />

asynchronous motors<br />

with breaking whilst<br />

running.<br />

The current broken (Ic)<br />

in category AC-3 is<br />

equal to the rated<br />

operational current (Ie)<br />

of the motor.<br />

Millions of operating cycles<br />

Current broken in A<br />

Operational power in kW-50 Hz<br />

Example<br />

Asynchronous motor with P = 5.5 kW -Ue =400 V-Ie =11 A - Ic = Ie =11 A<br />

or asynchronous motor with P = 5.5 kW -Ue = 415 V-Ie =11 A-Ic = Ie = 11 A<br />

3 million operating cycles required.<br />

The above selection curves show the contactor rating needed: LC1-D18.<br />

Use in category AC-3 (Ue =660/690 V) (1)<br />

Control of 3-phase<br />

asynchronous motors<br />

with breaking whilst<br />

running.<br />

The current broken (Ic)<br />

in category AC-3 is<br />

equal to the rated<br />

operational current (Ie)<br />

of the motor.<br />

Millions of operating cycles<br />

Current broken in A<br />

(1) For Ue = 1000 V use the 660/690 V curves, but do not exceed the operational current at the operational power<br />

indicated for 1000 V.<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

4<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3

Selection guide according<br />

to required electrical<br />

durability (continued)<br />

<strong>TeSys</strong> contactors<br />

For utilisation category AC-3<br />

Use in category AC-3 (Ue ≤ 440 V)<br />

Control of 3-phase<br />

asynchronous motors<br />

with breaking whilst<br />

running.<br />

The current broken (Ic)<br />

in category AC-3 is<br />

equal to the rated<br />

operational current (Ie)<br />

of the motor.<br />

Millions of operating cycles<br />

Current broken in A<br />

Operational power in kW-50 Hz<br />

Example<br />

Asynchronous motor with P = 132 kW -Ue = 380 V-Ie = 245 A - Ic = Ie = 245 A<br />

or asynchronous motor with P = 132 kW -Ue = 415 V-Ie = 240 A - Ic = Ie = 240 A<br />

1.5 million operating cycles required.<br />

The above selection curves show the contactor rating needed: LC1-F330.<br />

(1) The dotted lines are only applicable to contactors LC1-BL.<br />

Use in category AC-3 (Ue =660/690 V)<br />

Control of 3-phase<br />

asynchronous motors<br />

with breaking whilst<br />

running.<br />

The current broken (Ic)<br />

in category AC-3 is<br />

equal to the rated<br />

operational current (Ie)<br />

of the motor.<br />

Millions of operating cycles<br />

Current broken in A<br />

Example<br />

Asynchronous motor with P = 132 kW - Ue = 660 V - Ie = 140 A - Ic = Ie = 140 A<br />

1.5 million operating cycles required.<br />

The above selection curves show the contactor rating needed: LC1-F330.<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

(1) The dotted lines are only applicable to contactors LC1-BL.<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3

Selection<br />

<strong>TeSys</strong> contactors<br />

For utilisation category AC-1<br />

Maximum operational current (open-mounted device)<br />

Contactor<br />

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

size LP1- LP1- LP1-<br />

K09 K12 D09 D12 D18 D25 D32 D38 D40<br />

DT20 DT25 DT32 DT40 DT60<br />

Maximum operating rate<br />

in operating cycles/hour 600 600 600 600 600 600 600 600 600 600 600<br />

Connections/ cable c.s.a. mm 2 4 4 4 4 4 6 6 10 16 10 16<br />

cabling conforming<br />

to IEC 947-1 bar size mm – – – – – – – – – – –<br />

Operational current<br />

in AC-1 in A, ≤ 40 °C A 20 20 25 20 25 32 40 50 60 50 60<br />

according to the<br />

ambient temperat- ≤ 60 °C A 20 20 25 20 25 32 40 50 60 50 60<br />

ure, conforming to<br />

IEC 947-1 ≤ 70 °C A (at Uc)(1) (1) 17 (1) 17 22 28 35 45 35 42<br />

Maximum 220/230 V kW 8 8 9 8 9 11 14 18 21 18 21<br />

operational<br />

power 240 V kW 8 8 9 8 9 12 15 19 23 19 23<br />

≤ 60 °C<br />

380/400 V kW 14 14 15 14 15 20 25 31 37 31 37<br />

415 V kW 14 14 17 14 17 21 27 34 41 34 41<br />

440 V kW 15 15 18 15 18 23 29 36 43 36 43<br />

500 V kW 17 17 20 17 20 23 33 41 49 41 49<br />

660/690 V kW 22 22 27 22 27 34 43 54 65 54 65<br />

1000 V kW – – – – – – – – – – 70<br />

(1) Please consult your Regional Sales Office.<br />

Increase in operational current by parallelling of poles<br />

Apply the following multiplying factors to the current values given above. The factors take into account the often unbalanced<br />

current distribution between phases: - 2 poles in parallel: K = 1.6<br />

- 3 poles in parallel: K = 2.25<br />

- 4 poles in parallel: K = 2.8<br />

Selection according to required electrical durability, in category AC-1 (Ue ≤ 440 V)<br />

Millions of operating cycles<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1,5<br />

LC1, LP1, LP4-K09<br />

LC1, LP1, LP4-K12<br />

LC1-D09<br />

LC1-DT20<br />

LC1-D12<br />

LC1-DT25<br />

LC1-D18<br />

LC1-DT32<br />

LC1-D25<br />

LC1-DT40<br />

LC1-D32, LC1-D38<br />

LC1-DT60<br />

LC1, LP1-D40<br />

LC1-D50<br />

LC1, LP1-D65<br />

LC1, LP1-D80<br />

LC1-D95<br />

LC1-D115<br />

LC1-D150<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

Characteristics:<br />

pages 24505/2 to 24505/7<br />

24561_Ver2.20-EN.fm/2<br />

0,1<br />

1 2 3 4 6 8 10<br />

20 25 32 40 50 60 80 100 125 200 250 400<br />

Current broken in A<br />

Control of resistive circuits (cos ϕ ≥ 0.95).<br />

The current broken (Ic) in category AC-1 is equal to the current (Ie) normally drawn by the load.<br />

Example: Ue = 220 V - Ie = 50 A - θ≤40 °C - Ic = Ie = 50 A.<br />

2 million operating cycles required.<br />

The above selection curves show the contactor rating needed: either LC1 or LP1-D50.<br />

References:<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes:<br />

pages 24531/2 to 24532/3<br />

Schneider Electric

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

LP1- LP1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

600 600 600 600 600 600 600 600 600 600 600 600 600 600 600 120 120 120 120<br />

25 25 50 50 120 120 150 185 185 240 – – – – – – – – –<br />

2 2 2 2 2 2 2 2 2<br />

– – – – – – – – – – 30 x 5 40 x 5 60 x 5 100 x 5 60 x 5 50 x 5 80 x 5 100 x 5 100 x 10<br />

80 80 125 125 250 250 275 315 350 400 500 700 1000 1600 1000 800 1250 2000 2750<br />

80 80 125 125 200 200 275 280 300 360 430 580 850 1350 850 700 1100 1750 2400<br />

56 56 80 80 160 160 180 200 250 290 340 500 700 1100 700 600 900 1500 2000<br />

29 29 45 45 80 80 90 100 120 145 170 240 350 550 350 300 425 700 1000<br />

31 31 49 49 83 83 100 110 125 160 180 255 370 570 370 330 450 800 1100<br />

50 50 78 78 135 135 165 175 210 250 300 430 600 950 600 500 800 1200 1600<br />

54 54 85 85 140 140 170 185 220 260 310 445 630 1000 630 525 825 1250 1700<br />

58 58 90 90 150 150 180 200 230 290 330 470 670 1050 670 550 850 1400 2000<br />

65 65 102 102 170 170 200 220 270 320 380 660 750 1200 750 600 900 1500 2100<br />

86 86 135 135 235 235 280 300 370 400 530 740 1000 1650 1000 800 1100 1900 2700<br />

85 100 120 120 345 345 410 450 540 640 760 950 1500 2400 1500 1100 1700 3000 4200<br />

Millions of operating cycles<br />

10<br />

8<br />

6<br />

4<br />

2<br />

LC1-F185<br />

LC1-F225<br />

LC1-F265<br />

LC1-F330<br />

LC1-F400<br />

LC1-F500<br />

LC1-F630<br />

LC1-F800<br />

LC1-F780<br />

LC1-BL, BM<br />

LC1-BP<br />

LC1-BR<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

(1)<br />

0,2<br />

(1) The dotted lines are only applicable<br />

0,1<br />

to LC1-F225 contactors.<br />

20 40 50 60 80 100 200 300 350 600 800 1000 1600 2000 4000<br />

275 315 400 500 700<br />

Current broken in A<br />

Example: Ue = 220 V - Ie = 500 A - θ≤40 °C - Ic = Ie = 500 A.<br />

2 million operating cycles required.<br />

The above selection curves show the contactor rating needed: LC1-F780.<br />

Schneider Electric<br />

24561_Ver2.20-EN.fm/3

Selection guide<br />

<strong>TeSys</strong> contactors<br />

For utilisation categories AC-2 or AC-4<br />

Maximum breaking current<br />

Category AC-2: slip ring motors - breaking the starting current<br />

Category AC-4: squirrel cage motors - breaking the starting current<br />

Contactor LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

size LP1- LP1- LP1-<br />

K06 K09 K12 D09 D12 D18 D25 D32 D38 D40<br />

In category AC-4 (Ie max)<br />

- Ue ≤ 440 V<br />

Ie max broken = 6 x I motor A 36 54 54 54 72 108 150 192 192 240<br />

- 440 V < Ue ≤ 690 V<br />

Ie max broken = 6 x I motor A 26 40 40 40 50 70 90 105 105 150<br />

Depending on the maximum operating rate (1) and the on-load factor, θ ≤ 60 °C (2)<br />

From 150 & 15 % to 300 &10 % A 20 30 30 30 40 45 75 80 80 110<br />

From 150 & 20 % to 600 &10 % A 18 27 27 27 36 40 67 70 70 96<br />

From 150 & 30 % to 1200 & 10 % A 16 24 24 24 30 35 56 60 60 80<br />

From 150 & 55 % to 2400 & 10 % A 13 19 19 19 24 30 45 50 50 62<br />

From 150 & 85 % to 3600 & 10 % A 10 16 16 16 21 25 40 45 45 53<br />

(1) Do not exceed the maximum number of mechanical operating cycles.<br />

(2) For temperatures higher than 60 °C, use an operating rate value equal to 80% of the actual value when selecting from<br />

Plugging<br />

The current varies from the maximum plug-braking current to the rated motor current.<br />

The making current must be compatible with the rated making and breaking capacities of the contactor.<br />

As breaking normally takes place at a current value at or near the locked rotor current, the contactor can be selected<br />

Permissible AC-4 power rating for 200 000 operating cycles<br />

Operational voltage LC/- LC/- LC/- LC/- LC/- LC/- LC/- LC/- LC/- LC/-<br />

LP/- LP/- LP/-<br />

K06 K09 K12 D09 D12 D18 D25 D32 D38 D40<br />

220/230 V kW 0.75 1.1 1.1 1.5 1.5 2.2 3 4 4 4<br />

380/400 V kW 1.5 2.2 2.2 2.2 3.7 4 5.5 7.5 7.5 9<br />

415 V kW 1.5 2.2 2.2 2.2 3 3.7 5.5 7.5 7.5 9<br />

440 V kW 1.5 2.2 2.2 2.2 3 3.7 5.5 7.5 7.5 11<br />

500 V kW 2.2 3 3 3 4 5.5 7.5 9 9 11<br />

660/690 V kW 3 4 4 4 5.5 7.5 10 11 11 15<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3<br />

24566_Ver2.00-EN.fm/2<br />

Schneider Electric

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

300 390 480 570 630 830 1020 1230 1470 1800 2220 2760 3360 4260 3690 4320 5000 7500 9000<br />

170 210 250 250 540 640 708 810 1020 1410 1830 2130 2760 2910 2910 4000 4800 5400 6600<br />

140 160 200 200 280 310 380 420 560 670 780 1100 1400 1600 1600 2250 3000 4500 5400<br />

120 148 170 170 250 280 350 400 500 600 700 950 1250 1400 1400 2000 2400 3750 5000<br />

100 132 145 145 215 240 300 330 400 500 600 750 950 1100 1100 1500 2000 3000 3600<br />

80 110 120 120 150 170 240 270 320 390 450 600 720 820 820 1000 1500 2000 2500<br />

70 90 100 100 125 145 170 190 230 290 350 500 660 710 710 750 1000 1500 1800<br />

the above tables.<br />

using the criteria for categories AC-2 and AC-4.<br />

LC/- LC/- LC/- LC/- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

D50 D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

5.5 7.5 7.5 9 9 11 18.5 22 28 33 40 45 55 63 63 90 110 150 200<br />

11 11 15 15 18.5 22 33 40 51 59 75 80 100 110 110 160 160 220 250<br />

11 11 15 15 18.5 22 37 45 55 63 80 90 100 110 110 160 160 250 280<br />

11 15 15 15 18.5 22 37 45 59 63 80 100 110 132 132 160 200 250 315<br />

15 18.5 22 22 30 37 45 55 63 75 90 110 132 150 150 180 200 250 355<br />

18.5 22 25 25 30 45 63 75 90 110 129 140 160 185 185 200 250 315 450<br />

Schneider Electric<br />

24566_Ver2.00-EN.fm/3

Selection according to<br />

required electrical durability<br />

<strong>TeSys</strong> contactors<br />

For utilisation categories AC-2 or AC-4<br />

Use in categories AC-2 or AC-4 (Ue ≤ 440 V)<br />

Control of 3-phase asynchronous<br />

squirrel cage motors (AC-4) or slip<br />

ring motors (AC-2) with breaking<br />

whilst motor stalled.<br />

The current broken (Ic) in category<br />

AC-2 is equal to 2.5 x Ie.<br />

The current broken (Ic) in category<br />

AC-4 is equal to 6 x Ie.<br />

(Ie = rated operational current of the<br />

motor)<br />

Millions of operating cycles<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

LC1, LP1, LP4-K06<br />

LC1, LP1, LP4-K09,K12<br />

LC1-D09<br />

LC1-D12<br />

LC1-D18<br />

LC1-D25<br />

LC1-D32, D38<br />

LC1-D40<br />

LC1-D50<br />

LC1-D65<br />

LC1-D80<br />

LC1-D95<br />

LC1-D115<br />

LC1-D150<br />

0,1<br />

0,08<br />

0,06<br />

0,05<br />

0,04<br />

0,03<br />

0,02<br />

(1)<br />

0,01<br />

5 6 7 8 9 10 20 30 36 40 5054 72 80 108 150 192 240 300 390 480 570 630 828 1000<br />

Current broken in A<br />

Example<br />

Asynchronous motor with P = 5.5 kW - Ue = 400 V - Ie = 11 A<br />

Ic = 6 x Ie = 66 A<br />

or asynchronous motor with P = 5.5 kW - Ue = 415 V - Ie = 11 A<br />

Ic = 6 x Ie = 66 A<br />

200 000 operating cycles required.<br />

The above selection curves show the contactor rating needed: LC1-D25.<br />

(1) The dotted lines are only applicable to LC1, LP1-K12 contactors<br />

Utilisation in category AC-4 (440 V < Ue ≤ 690 V)<br />

Control of 3-phase asynchronous<br />

squirrel cage motors with breaking<br />

whilst motor stalled.<br />

The current broken (Ic) in category<br />

AC-2 is equal to 2.5 x Ie.<br />

The current broken (Ic) in category<br />

AC-4 is equal to 6 x Ie.<br />

(Ie = rated operational current of the<br />

motor)<br />

Millions of operating cycles<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

LC1-D09<br />

LC1-D12<br />

LC1-D18<br />

LC1-D25<br />

LC1-D32, D38<br />

LC1-D40<br />

LC1-D50<br />

LC1-D65<br />

LC1-D80<br />

LC1-D95<br />

LC1-D115<br />

LC1-D150<br />

0,1<br />

0,08<br />

0,07<br />

0,06<br />

0,05<br />

0,04<br />

0,03<br />

0,02<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

24566_Ver2.00-EN.fm/4<br />

0,01<br />

5 6 7 8 9 10 20 30 40 50 70 90 105 150 170 210 250 300 400 500 540 640 800 1000<br />

Current broken in A<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3<br />

Schneider Electric

Selection according to<br />

electrical durability<br />

<strong>TeSys</strong> contactors<br />

For utilisation categories AC-2 or AC-4<br />

Use in categories AC-2 or AC-4 (Ue ≤ 440 V)<br />

Control of 3-phase asynchronous<br />

squirrel cage motors (AC-4) or slip<br />

ring motors (AC-2) with breaking<br />

whilst motor stalled.<br />

The current broken (Ic) in category<br />

AC-4 is equal to 6 x Ie.<br />

(Ie = rated operational current of the<br />

motor)<br />

Millions of operating cycles<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

LC1-F185<br />

LC1-F225<br />

LC1-F265<br />

LC1-F330<br />

LC1-F400<br />

LC1-F500<br />

LC1-F630<br />

LC1-F800<br />

LC1-F780<br />

LC1-BL, BM<br />

LC1-BP<br />

LC1-BR<br />

0,1<br />

0,08<br />

0,06<br />

0,04<br />

0,02<br />

0,01<br />

100 200 400 600 800 1020 1470 2220 3360 42605000 8000 20 000<br />

1230 1800 2760 3690 6000 10 000<br />

Current broken in A<br />

Example<br />

Asynchronous motor with P = 90 kW - Ue = 380 V - Ie = 170 A<br />

Ic = 6 x Ie = 1020 A<br />

or asynchronous motor with P = 90 kW - Ue = 415 V - Ie = 165 A<br />

Ic = 6 x Ie = 990 A<br />

60 000 operating cycles required<br />

The above selection curves show the contactor rating needed: LC1-F265.<br />

Use in category AC-4 (440 V < Ue ≤ 690 V)<br />

Control of 3-phase asynchronous<br />

squirrel cage motors with breaking<br />

whilst motor stalled..<br />

The current broken (Ic) in category<br />

AC-4 is equal to 6 x Ie.<br />

(Ie = rated operational current of the<br />

motor)<br />

Millions of operating cycles<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

LC1-F185<br />

LC1-F225<br />

LC1-F265<br />

LC1-F330<br />

LC1-F400<br />

LC1-F500<br />

LC1-F630<br />

LC1-F780, F800<br />

LC1-BL, BM<br />

LC1-BP<br />

LC1-BR<br />

0,1<br />

0,08<br />

0,06<br />

0,04<br />

0,02<br />

0,01<br />

100 200 400 600 800 1000 2000 4000 8000 10 000 20 000<br />

Current broken in A<br />

Characteristics :<br />

pages 24505/2 to 24505/7<br />

References :<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes :<br />

pages 24531/2 to 24532/3<br />

Schneider Electric<br />

24566_Ver2.00-EN.fm/5

Selection<br />

<strong>TeSys</strong> contactors<br />

For utilisation categories DC-1 to DC-5<br />

Rated operational current (Ie) in Amperes, in utilisation category DC-1, resistive loads:<br />

Rated operational Number of poles Contactor rating (1)<br />

voltage connected in LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

Ue series LP1-<br />

D09 D12 D18 D25 D32 D38 D40 D50<br />

DT20 DT25 DT32 DT40 DT60<br />

– +<br />

– +<br />

24 V 1 20 20 20 25 32 40 40 40 50 65<br />

2 20 20 20 25 32 40 40 40 50 65<br />

3 20 20 20 20 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

48/75 V 1 20 20 20 25 32 40 40 40 50 65<br />

2 20 20 20 25 32 40 40 40 50 65<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

125 V 1 4 4 4 4 7 7 7 7 7 7<br />

2 20 20 20 25 32 40 40 40 50 65<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

225 V 1 1 1 1 1 1 1 1 1 1 1<br />

2 4 4 4 4 7 7 7 7 7 7<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

300 V 3 – – – – – – – – – –<br />

4 – 20 20 – 32 40 – – 50 –<br />

460 V 1 – – – – – – – – – –<br />

4 – – – – – – – – – –<br />

900 V 2 – – – – – – – – – –<br />

1200 V 3 – – – – – – – – – –<br />

1500 V 4 – – – – – – – – – –<br />

Rated operational current (Ie) in Amperes, in utilisation category DC-2 to DC-5, inductive loads:<br />

Rated operational Number of poles Contactor rating (1)<br />

voltage connected in LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

Ue series LP1-<br />

D09 D12 D18 D25 D32 D38 D40 D50<br />

DT20 DT25 DT32 DT40 DT60<br />

– +<br />

– +<br />

24 V 1 20 20 20 25 32 40 40 40 50 65<br />

2 20 20 20 25 32 40 40 40 50 65<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

48/75 V 1 8 8 8 8 32 40 40 40 50 65<br />

2 20 20 20 25 32 40 40 40 50 65<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

125 V 1 2 2 2 2 3 3 3 3 4 4<br />

2 15 15 15 15 32 40 40 40 50 65<br />

3 20 20 20 25 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

225 V 1 0.5 0.5 0.5 0.5 1 1 1 1 1 1<br />

2 2 2 2 2 3 3 3 3 4 4<br />

3 8 8 8 8 32 40 40 40 50 65<br />

4 – 20 20 – 32 40 – – 50 –<br />

300 V 3 – – – – – – – – – –<br />

4 – 8 8 – 32 40 – – 50 –<br />

1 – – – – – – – – – –<br />

460 V 4 – – – – – – – – – –<br />

900 V 2 – – – – – – – – – –<br />

Characteristics:<br />

pages 24505/2 to 24505/7<br />

24560_Ver2.20-EN.fm/2<br />

1200 V 3 – – – – – – – – – –<br />

1500 V 4 – – – – – – – – – –<br />

(1) For rated operational currents of contactors LC1 and LP1-K: please consult your Regional Sales Office.<br />

References:<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes:<br />

pages 24531/2 to 24532/3<br />

Schneider Electric

time constant L ≤ 1 ms, ambient temperature ≤ 60 °C (2)<br />

R<br />

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

LP1- LP1-<br />

D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

7 12 12 200 200 210 230 270 320 380 520 760 1180 760 700 1100 1750 2400<br />

65 100 100 200 200 210 230 270 320 380 520 760 1180 760 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

1.5 1.5 1.5 10 10 – – – – – – – – – 700 1100 1750 2400<br />

7 12 12 200 200 190 200 250 280 350 450 700 1000 700 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

– – – 200 200 190 200 250 280 350 450 700 1000 700 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1000 850 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – 200 – 190 200 250 280 350 450 700 1000 700 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

time constant L ≤ 15 ms, ambient temperature ≤ 60 °C (2)<br />

R<br />

LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1- LC1-<br />

LP1- LP1-<br />

D65 D80 D95 D115 D150 F185 F225 F265 F330 F400 F500 F630 F780 F800 BL BM BP BR<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850<br />

65 100 100 200 200 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

4 5 5 200 200 – – – – – – – – – 700 1100 1750 2400<br />

65 40 40 200 200 160 180 250 300 350 500 700 1000 700 700 1100 1750 2400<br />

65 60 60 200 200 240 240 280 310 350 550 850 1000 850 700 1100 1750 2400<br />

65 72 – 200 – 240 240 280 310 350 550 850 1000 850 700 1100 1750 2400<br />

1.5 2 2 3 3 – – – – – – – – – 700 1100 1750 2400<br />

4 5 5 200 200 140 160 220 280 310 480 680 900 680 700 1100 1750 2400<br />

65 100 100 200 200 160 180 250 300 350 500 700 1000 700 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

– – – 200 200 140 160 220 280 310 480 680 900 680 700 1100 1750 2400<br />

65 100 – 200 – 240 260 300 360 430 580 850 1300 850 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – 200 – 140 160 220 280 310 480 680 800 680 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

– – – – – – – – – – – – – – 700 1100 1750 2400<br />

(2) Contactors LC1-F and LC1-B operating at an ambient temperature of 40 °C, have higher operational currents: please consult your Regional Sales Office.<br />

Schneider Electric<br />

24560_Ver2.20-EN.fm/3

Selection<br />

according to required<br />

electrical durability<br />

<strong>TeSys</strong> contactors<br />

For utilisation categories DC-1 to DC-5<br />

Use in categories DC-1 to DC-5<br />

The criteria for contactor selection are:<br />

- the rated operational current Ie,<br />

- the rated operational voltage Ue,<br />

- the utilisation category and the time constant L/R,<br />

- the required electrical durability.<br />

Maximum operating rate (operating cycles)<br />

The following operating rate must not be exceeded: 120 operating cycles/hour at rated operational current Ie.<br />

Electrical durability<br />

Millions of operating cycles<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

0,8<br />

0,6<br />

LC1-D09, DT20<br />

LC1-DT25, LC1, LP1-D12<br />

LC1-D18, DT32<br />

LC1-DT40, LC1, LP1-D25<br />

LC1-D32, D38,<br />

DT60<br />

LC1, LP1-D40<br />

LC1-D50<br />

LC1, LP1-D65<br />

LC1, LP1-D80<br />

LC1-D95<br />

LC1-D115, D150<br />

0,4<br />

0,2<br />

0,1<br />

0,08<br />

0,06<br />

0,04<br />

0,02<br />

0,01<br />

0,2 0,3 0,4 0,5 0,6 0,8<br />

0,7 0,9<br />

1<br />

2 3 4 5 6 7 9 14 20 30 40 50 60 70 90100<br />

8 10 16 24 32 36<br />

80<br />

Example<br />

Series wound motor: P = 1.5 kW - Ue = 200 V - Ie = 7.5 A. Utilisation: reversing, inching.<br />

Utilisation category = DC-5.<br />

- Select contactor LC1-D25 or LP1-D25 with 3 poles in series.<br />

- The power broken is: Pc total = 2.5 x 200 x 7.5 = 3.75 kW.<br />

- The power broken per pole is: 1.25 kW.<br />

- The electrical durability read from the curve is ≥ 10 6 operating cycles.<br />

Power broken per pole in kW<br />

Use of poles in parallel<br />

Electrical durability can be increased by using poles connected in parallel.<br />

With N connected in parallel, the electrical durability becomes: electrical durability read from the curves x N x 0.7.<br />

Note 1<br />

When the poles are connected in parallel, the maximum operational currents indicated on pages 24560/2 and 24560/3<br />

must not be exceeded.<br />

Note 2<br />

Ensure that the connections are made in such a way as to equalise the currents in each pole.<br />

Characteristics:<br />

pages 24505/2 to 24505/7<br />

References:<br />

pages 24501/2 to 24502/3<br />

Dimensions, schemes:<br />

pages 24531/2 to 24532/3<br />

24560_Ver2.20-EN.fm/4<br />