R 1200 CL

R 1200 CL

R 1200 CL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

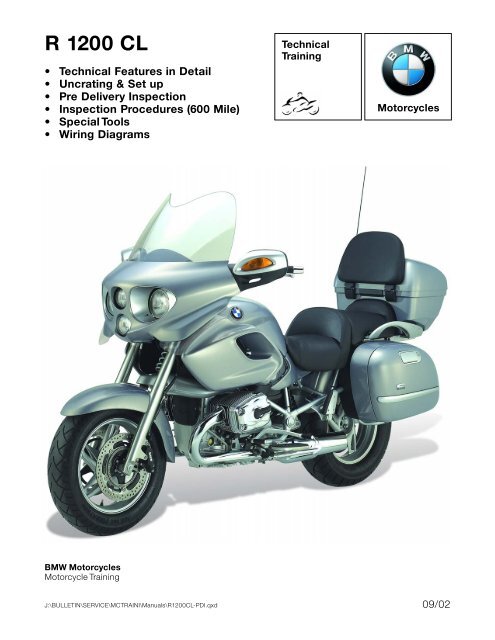

R <strong>1200</strong> <strong>CL</strong><br />

• Technical Features in Detail<br />

• Uncrating & Set up<br />

• Pre Delivery Inspection<br />

• Inspection Procedures (600 Mile)<br />

• Special Tools<br />

• Wiring Diagrams<br />

BMW Motorcycles<br />

Motorcycle Training<br />

J:\BULLETIN\SERVICE\MCTRAINI\Manuals\R<strong>1200</strong><strong>CL</strong>-PDI.qxd<br />

Technical<br />

Training<br />

Motorcycles<br />

09/02

R <strong>1200</strong> <strong>CL</strong><br />

Disclaimer<br />

This training reference book is not intended to be a complete and all inclusive<br />

source of servicing, repairing or troubleshooting the motorcycle. This is only part<br />

of the training information designed to ensure that uniform procedures and<br />

information are presented to all participants of Technical Training conducted by<br />

BMW Motorcycles.<br />

The technician must always refer to and adhere to the following official BMW<br />

Motorrad and BMW North America, Inc service publications.<br />

• Training Materials<br />

• Repair Manuals<br />

• Service Bulletins<br />

• MoDiTeC<br />

Service Bulletins are issued by the BMW Motorcycle Service Department,<br />

regarding changes in operation, and repair or maintenance procedures. Service<br />

Bulletins are available on MTAS (www.bmwmc.net). From the departments menu<br />

button on the home page, select “On-line bulletin search”.<br />

Information Status, (date indicated on front cover).<br />

For changes/additions to the technical data, please refer to current information<br />

issued by the BMW NA Motorcycle Service Department.<br />

BMW of North America, LLC<br />

BMW Motorcycles<br />

ZU-X-S-51<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

Table of Contents<br />

Subject Page<br />

Technical Features in Detail<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2<br />

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Digital Motor Electronics (MA 2.4) . . . . . . . . . . . . . . . . . . . . . 10<br />

Chassis and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Brakes (Integral ABS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Cockpit and Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

Electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32<br />

Sound and Communication Systems. . . . . . . . . . . . . . . . . . . 36<br />

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38<br />

Pre Delivery Inspection Procedures . . . . . . . . . . . . . . . . . . . . . 42<br />

Retail Delivery Handover Procedure . . . . . . . . . . . . . . . . . . . . . 61<br />

600 Mile Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . 64<br />

New Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78<br />

Wiring Diagrams<br />

Terminal & Electrical Component Designation Legend . . . . . 83<br />

Power Distribution & Grounds . . . . . . . . . . . . . . . . . . . . . . . . 85<br />

Starter & Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89<br />

Motronic MA 2.4 Engine Management. . . . . . . . . . . . . . . . . . 91<br />

Anti-lock Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97<br />

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99<br />

Instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101<br />

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105<br />

Horn,Turn Indicators with Hazard Flashers . . . . . . . . . . . . . . 107<br />

Radio/CD Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109<br />

Heated Grips/Seat and Diagnostic Plug . . . . . . . . . . . . . . . . 111<br />

Alarm System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113<br />

Electrical Component Location Charts . . . . . . . . . . . . . . . . . . 115<br />

Alarm System Components and Programming Information. . 121<br />

R <strong>1200</strong> <strong>CL</strong> Introduction<br />

1

R <strong>1200</strong> <strong>CL</strong><br />

Introduction<br />

The new R <strong>1200</strong> <strong>CL</strong> luxury Cruiser:<br />

individual product personality, visual<br />

appeal featuring unique specifications in<br />

the Cruiser segment.<br />

The distinctive look of the new BMW<br />

boxer flat-twin appeals to the taste of the<br />

individual motorcyclist.<br />

This introduction brochure describes the<br />

technology that lies beneath the skin of the<br />

new BMW R <strong>1200</strong> <strong>CL</strong> in detail as well as<br />

2<br />

Pearl Silver Metallic<br />

uncrating, set up, PDI and maintenance<br />

information. However, allways refer to technical<br />

data in the relevant publications found<br />

the Service and Technical Training areas of<br />

MTAS.<br />

MTAS (Motorcycle Training Administration<br />

System), http://www.bmwmc.net.<br />

We hope you enjoy reading this brochure.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Introduction<br />

Overview. Assembled at the Berlin plant<br />

with its sister models, the R <strong>1200</strong> <strong>CL</strong> is yet<br />

another milestone for BMW Motorcycles. It<br />

takes its place in the line up of previously<br />

introduced R <strong>1200</strong> C models including the<br />

Classic introduced in 1997, and the later<br />

model variants including the R <strong>1200</strong> C<br />

Montana, Euro, Stilleto and Phoenix, all of<br />

which have laid the foundation for an<br />

extremely successful series.<br />

The name identifies the character of this<br />

new R Series addition; R <strong>1200</strong> <strong>CL</strong>: Cruiser<br />

and Luxury, comfort with everyday suitability<br />

and a powerful appearance.<br />

In addition to the Pearl Silver Metallic shown<br />

on the previous page, color choices at time<br />

of introduction also include:<br />

Mojave Brown Metallic<br />

Capri Blue Metallic<br />

Technical Features in Detail<br />

Equipment Levels. There are two versions;<br />

the base R <strong>1200</strong> <strong>CL</strong> and the higher<br />

trim level R <strong>1200</strong> <strong>CL</strong>C (custom).<br />

In addition to the Fully Integral ABS, other<br />

upgrades are provided as standard equipment<br />

on the base R <strong>1200</strong> <strong>CL</strong> including:<br />

• cruise control,<br />

• two-stage heated grips,<br />

• chrome package,<br />

• and prewiring for the factory stereo<br />

radio/single disc CD player.<br />

The R <strong>1200</strong> <strong>CL</strong>C is additionally equipped<br />

with:<br />

• stereo radio / single disc CD player<br />

with handlebar mounted control,<br />

• heated, comfort seat.<br />

Accessories. Accessories are also available<br />

for both versions including:<br />

• plug in Factory Alarm System,<br />

• Comfort-Squab (separate backrest)<br />

• Top Case Speakers<br />

• Floorboard footrest for passenger<br />

• Cup holder (like K <strong>1200</strong> LT)<br />

• BC-V.O.I.C.E. Board Communications - Voice<br />

Operated Intercom Communication Equipment.<br />

• CB Radio and antenna<br />

• Luggage soft bag inserts for side cases<br />

• Cylinder head engine protection bars<br />

• Side case protection bars<br />

Image.The distinctive fairing silhouette with<br />

the four headlights and innovative bodywork<br />

design integrated standard top and<br />

side case storage concept tempt you to get<br />

on and ride. The riding position, designed<br />

for good handling, provides direct contact<br />

with the motorcycle thanks to the wide handlebars<br />

and low, comfortable seat.<br />

A standard seat height of 745 mm (29.3”)<br />

has been designed intentionally low for all<br />

riders in order to ensure easy control over<br />

the motorcycle when in standing position.<br />

3

R <strong>1200</strong> <strong>CL</strong><br />

Engine<br />

The proven <strong>1200</strong> cc R 259 variant, with<br />

high-camshaft-valve control and four<br />

valves is fitted in the R <strong>1200</strong> <strong>CL</strong> unchanged.<br />

The engine cooling system is handled by<br />

twin oil-coolers integrated in the front<br />

frame. Oil circulation is supplied by its own<br />

oil pump, regulated by a thermostat.The oil<br />

flows through both oil coolers in succession;<br />

lubricating oil and cooling oil are separated.<br />

Engine management is controlled by the<br />

Motronic MA 2.4. in conjunction with the performance-determining<br />

components, such s<br />

camshafts, valve sizes, air intake design, the R<br />

<strong>1200</strong> <strong>CL</strong> engine is also designed in such a<br />

4<br />

way that a torque range desired for a luxury<br />

Cruiser is attained. The engine output of the<br />

R <strong>1200</strong> <strong>CL</strong> is 45 KW (61 bhp) at 5000 RPM,<br />

the maximum torque 98 Nm (71 ft/lb) at<br />

3000 RPM.<br />

The engine’s displacement and dynamic<br />

specifications are:<br />

Displacement = 1170 cc<br />

Bore x Stroke = 101 mm x 73 mm<br />

Pistons = short skirt light alloy box piston<br />

Compression Ratio = 10.0:1,<br />

Camshaft profile = 256°<br />

The exhaust system is designed according<br />

to the bikes cruiser characteristic.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Engine<br />

The two piece light alloy crankcase is manufactured<br />

using a pressure die-casting<br />

method.The oil pan, which holds 3.75 litres,<br />

is integrated into the engine case halves.<br />

As with all R Series bikes, the engine and<br />

gearbox is a combined load bearing element<br />

of the chassis. For this reason, both<br />

case halves were designed with a specific<br />

rigidity with the aid of computer calculations<br />

of the Finite Element Method.<br />

The 1-piece forged crankshaft is accommodated<br />

centrally in the crankcase on sliding<br />

bearings. It runs on two bearings, the rear<br />

bearing being larger and designed as a<br />

double collar bearing. The 125 mm long<br />

connecting rods are made of sintered steel<br />

and are cracked at the big end.<br />

The weight-optimized box pistons are made<br />

of light alloy and have machined valve<br />

notches on the piston crown. A pressure<br />

release channel above the piston ring zone<br />

prevents a partial vacuum from building up<br />

in the combustion chamber during engine<br />

cool down to prevent oil from being pulled<br />

in under vacuum when the engine is off.<br />

The camshafts are mounted into the cylinder<br />

heads by separate camshaft carriers.<br />

The cams are made up of a case-hardened<br />

shaft with pressed-on individual cams<br />

made of sintered material.<br />

The camshafts are roller chain driven at a<br />

2:1 ratio geared down by the auxiliary shaft,<br />

which is located below the crankshaft and<br />

also drives both duo-centric oil pumps.<br />

The valves all have 5 mm valve stems.They<br />

are actuated in pairs by clear chill cast tappets,<br />

short aluminum tappet push rods and<br />

forged valve lifters.<br />

Technical Features in Detail<br />

Engine Components<br />

Crankshaft / Pistons<br />

Cylinder head / Valve train<br />

5

R <strong>1200</strong> <strong>CL</strong><br />

Engine<br />

The engine is designed to run on premium<br />

grade fuel (95 RON/92 AKI).The air fuel mixture<br />

is ignited by a centrally placed spark<br />

plug.<br />

Directly connected to each spark plug are<br />

the new direct connection ignition coils (ie:<br />

F 650 CS). These coils eliminate the secondary<br />

spark plug wire ensuring consistent<br />

spark voltage over the lifetime of the motorcycle.<br />

Due to the ignition coils, the cylinder<br />

head covers are new.The ignition coils each<br />

have a separate ground wire that connects<br />

to the engine cylinder head.<br />

The exhaust system with a hard chrome<br />

plated surface is produced in three sections:<br />

two exhaust manifolds consisting of a<br />

55 mm double walled tube and a flangemounted,<br />

1-section exhaust silencer with<br />

short tail pipes.This has 4 chambers and is<br />

based on the reflection and absorption principle.<br />

In the exhaust silencer of the R <strong>1200</strong> <strong>CL</strong>, two<br />

catalytic converters are used. The small<br />

diameter and a flat design, offers a higher<br />

sectional flow. The cylindrical catalytic converter<br />

carriers have a diameter of 60 mm<br />

and a length of 74 mm.<br />

The heated O2 sensor is located in the<br />

exhaust gas stream of the two exhaust manifolds<br />

beyond the catalytic converters.<br />

During the warm-up period from 60° C<br />

motor oil temperature (just a few minutes<br />

after starting), it already ensures that the<br />

engine runs in accordance with the stoichiometric<br />

mixture (lambda=1).<br />

The catalytic converters are made of palladium<br />

and rhodium. Palladium accelerates<br />

the oxidation of hydrocarbons and carbon<br />

monoxide. Rhodium reduces nitric oxide.<br />

6<br />

New Ignition Coils<br />

Exhaust Components<br />

Twin Catalytic Converters, Single O 2 Sensor<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

Clutch<br />

Centrifugal mass is of advantage for Cruiser<br />

engine speeds. This is achieved by a solid<br />

clutch case cover with the R <strong>1200</strong> <strong>CL</strong>.<br />

The weight of the clutch disc on the other<br />

hand, with a diameter of only 165 mm, has<br />

been reduced in order to attain a fast standstill<br />

of the gear drive shaft.<br />

This optimizes the engaging and disengaging<br />

of the 6-speed gearbox.The wear resistant<br />

friction lining of the clutch disc together<br />

with the strong casing cover additionally<br />

offers high temperature resistance.<br />

R <strong>1200</strong> <strong>CL</strong> Introduction<br />

Clutch Components<br />

7

R <strong>1200</strong> <strong>CL</strong><br />

Gearbox<br />

The R <strong>1200</strong> <strong>CL</strong> is equipped with a new six<br />

speed Getrag gearbox exhibiting the gearbox<br />

codes:<br />

xxxxxJAE (BMW 7 673 702; GETRAG<br />

424.0.0003.04) = 6 speed, silver painted<br />

xxxxxJAF (BMW 7 673 703; GETRAG<br />

424.0.0003.05) = 6 speed, black painted<br />

8<br />

The first five gears are closely graduated<br />

enabling typical Cruiser riding. The sixth<br />

gear is geared considerably longer and is<br />

therefore designed as an overdrive providing<br />

pleasant touring with lower fuel consumption<br />

on interstate journeys.<br />

In the light alloy casing, three gear shafts<br />

are installed in wear-resistant clean-bearing<br />

deep groove ball bearings.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Gear Box<br />

The engaging and disengaging gears are<br />

located on the auxiliary shaft and the driven<br />

shaft. All driven gears are installed on lowfriction<br />

needle bearings.<br />

The new heal/toe shifter transfers the riders<br />

shift action to the gearbox through ball and<br />

pin pivots to the input shaft. The heal/toe<br />

shifter is made of chrome plated forged aluminum.<br />

Technical Features in Detail<br />

The aluminum shifter drum is fixed in the<br />

exact gear positions by a cam plate. The<br />

die-cast aluminum shifter forks are actuated<br />

by the shifting gates of the camshaft<br />

controllers via anti-friction steel bushes.The<br />

shifter forks glide smoothly on hollow bored<br />

steel shafts and engage the gears exactly.<br />

The gear pair of the primary drive has a quietly<br />

running, wear-resistant spiral gearing.<br />

All other gears are provided with a spur<br />

toothing and are constructed tightly interlocked.This<br />

provides smoother meshing for<br />

particularly quiet running.<br />

The hollow-bored drive shaft bears a compact,<br />

two phase starting damper. The rotational<br />

oscillations occurring during the idle<br />

speed of the engine are absorbed by a prestressed<br />

washer. A heavy-duty coil spring<br />

works in the main damper, which is responsible<br />

for reducing the noise occurring during<br />

the changing of gear and load.<br />

9

R <strong>1200</strong> <strong>CL</strong><br />

Digital Motor Electronics MA 2.4<br />

The R <strong>1200</strong> <strong>CL</strong> is equipped with Digital<br />

Motor Electronics (Motronic) MA 2.4<br />

engine management system. In contrast<br />

to the Motronic MA 2.4 for the R 1150<br />

models, an electronically regulated cold<br />

start control with idle speed control is<br />

used for the R <strong>1200</strong> <strong>CL</strong>. as on the R <strong>1200</strong><br />

C Classic.<br />

The MA 2.4 control module monitors engine<br />

operating parameters via input signals from<br />

sensors and switches.<br />

10<br />

These input values are evaluated by the<br />

control module and used for calculating the<br />

injection on time and frequency, optimum<br />

ignition timing angle and idle speed control<br />

based on programmed operating data<br />

maps.<br />

This system provides a consistent idle<br />

speed of 900 RPM at normal operating<br />

temperature as well as automatic increased<br />

speeds for cold engine startup which gradually<br />

changes as the engine warms up.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Digital Motor Electronics MA 2.4<br />

The fuel pump – together with a fuel pressure<br />

regulator – ensure that adequate fuel<br />

volume is available with constant pressure<br />

to the fuel injectors. The fuel pump is<br />

switched on by the fuel pump relay which is<br />

controlled by the MA 2.4 control module.The<br />

fuel system pressure in the distributor is<br />

constant 3 bar.<br />

The Motronic control module receives the<br />

most important input signals from the hall<br />

sensors (crankshaft rotational speed and<br />

top dead center piston position) and from<br />

the throttle position sensor (angular position<br />

of the throttle valves).<br />

Technical Features in Detail<br />

The air volume drawn in is calculated (Alphan-control)<br />

via the angle of the throttle valve<br />

(Alpha) and the engine speed. The fine-tuning<br />

takes place via an engine temperature<br />

sensor, and the air temperature sensor and<br />

the integrated barometric pressure sensor.<br />

The oxygen sensor monitors the amount of<br />

remaining oxygen content in the exhaust<br />

gas. This allows the control module to<br />

manipulate the fuel injector on time (Ti) to<br />

maintain the optimum air fuel mixture. All<br />

information is compared with the programmed<br />

characteristics in the control unit.<br />

11

R <strong>1200</strong> <strong>CL</strong><br />

Digital Motor Electronics MA 2.4<br />

The output signals for ignition and injection<br />

are amplified in the control module by integrated<br />

output transistors. The transistors<br />

switching on and off activates the fuel injector<br />

solenoid valves and the primary ignition<br />

coil windings.<br />

The cold-start control works with an actuator<br />

with a worm gear pair that directly actuates<br />

the two throttle valves in the intake<br />

manifold. The control signal is calculated<br />

from the signals of the engine temperature<br />

and from the speed of the crankshaft with<br />

response.<br />

The ideal positions of the throttle valves are<br />

set for all operational states by means of an<br />

adaptive control adjustment maintained by<br />

the control module.<br />

12<br />

The fuel injectors are small and light weight.<br />

They inject fuel once per crankshaft revolution<br />

in parallel.<br />

To achieve optimal running of the engine<br />

during the start-up and warming phase, fuel<br />

enrichment is provided by activating the<br />

injectors twice as often during starting<br />

phase, then switching over to the once per<br />

crankshaft revolution injection scheme with<br />

a longer ontime to proved enrichment. As<br />

the engine warms the on time is reduced.<br />

When the maximum engine speed of 7000<br />

rpm has been reached, the injection time is<br />

interrupted in order to limit the speed.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Digital Motor Electronics MA 2.4<br />

The Motronic is equipped with a fuel cut-off.<br />

If throttle valves are closed, an engine temperature<br />

is more than 70° C or an engine<br />

speed exceeds 1800 rpm, then the activation<br />

of the fuel injectors is interrupted.When<br />

the engine speed reduces to 1400 RPM or<br />

below, the injectors are reactivated.<br />

The failure of a sensor signal (with the<br />

exception of Hall sensors) is detected by<br />

the control module through electrical monitoring<br />

and plausibility. When this happens,<br />

a fault is set for the failed input signal and<br />

alternate default value is used allowing the<br />

motorcycle to continue running.<br />

Technical Features in Detail<br />

MA 2.4 communicates with BMW diagnostic<br />

equipment (MoDiTeC / GT 1) via the 10<br />

pin diagnostic plug located under the left<br />

side chrome cover.<br />

13

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

The R <strong>1200</strong> <strong>CL</strong> has a wheelbase of<br />

1641mm, which is actually 9mm shorter<br />

than the Classic. The rake angle and trail<br />

measurement have also been changed.<br />

The chassis geometry was re-considered<br />

for the R <strong>1200</strong> <strong>CL</strong> due to the wider tires and<br />

the different character required for a Luxury<br />

Cruiser. The angles were a calculated decision,<br />

resulting in both appearance and<br />

functionality. These changes necessitated<br />

the following new components specifically<br />

made for this bike;<br />

• 30 mm longer telelever control arm,<br />

• wider chrome plated upper fork bridge,<br />

• wider lower fork brace with repositioned<br />

ball joint mounting socket<br />

14<br />

Additionally, the attachment points for the<br />

brake calipers had to be modified to comply<br />

with the EVO caliper dimensions requiring<br />

new stanchion tubes for the front forks.<br />

The telelever control arm pivots at the<br />

engine mounting location on a continuous<br />

hollow shaft, which is held in maintenancefree<br />

ball bearings.<br />

The front frame section is made of die cast<br />

aluminum, which is the best method for<br />

moulding shapes and surfaces. It’s firmly<br />

attached to the crankcase at four points.<br />

The cast frame provides a mounting point<br />

for the new chrome plated, forged aluminum,<br />

upper fork bridge. The fork bridge<br />

steering bearings are reinforced doublerow<br />

flute bearings.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

To prevent rocking movements in the steering system, the fork tubes are mounted to the<br />

newly designed upper fork bridge by tilt decoupled barrel joints.<br />

The fork tubes are mounted 225 mm apart from each other and connected by a new<br />

chrome plated, forged aluminum, lower fork brace. It is mounted to the forks by bolts<br />

ensuring the rigidity of the front wheel location. The lower fork brace is connected to the<br />

30mm longer longitudinal control arm by the typical Telelever maintenance free ball joint.<br />

Technical Features in Detail<br />

15

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

The travel of the front wheel is damped by a<br />

central suspension strut with twin-sleeve<br />

damper principle. It provides 144 mm of<br />

front suspension travel.<br />

To review the changes in the chassis geometry<br />

we will compare the R <strong>1200</strong> C to the<br />

<strong>CL</strong>. But first lets review the basics of chassis<br />

geometry.<br />

Rake = The inclined angle that is created<br />

by an imaginary line through the steering<br />

pivots to the road surface.<br />

Trail = The distance, as measured along the<br />

ground, of the point at which the front tire<br />

contacts the ground and where the imaginary<br />

axis line of the steering pivots would<br />

contact the ground.<br />

By itself, the 30mm longer R <strong>1200</strong> <strong>CL</strong><br />

Telelever changes the rake angle to 56 O<br />

and increases the wheelbase by the same<br />

distance.<br />

However, the new lower fork brace repositions<br />

the steering pivot further forward on<br />

the fork brace, which moves the forks rearward<br />

reducing the overall wheelbase but<br />

increases the trail.<br />

Final chassis specifications of R <strong>1200</strong> C<br />

vs R <strong>1200</strong> <strong>CL</strong>:<br />

Rake angle:<br />

C = 60.5 O<br />

<strong>CL</strong> = 56 O<br />

Trail measurement:<br />

C = 86mm (3.38“)<br />

<strong>CL</strong> = 184mm (7.24“)<br />

Wheelbase:<br />

C = 1650 mm (65.0“)<br />

<strong>CL</strong> = 1641 mm (64.61“)<br />

16<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

The Monolever swing arm is fixed very rigidly<br />

– in central cast steel parts – in backlash<br />

free taper roller bearings, thereby resulting in<br />

a short, rigid connection between the bearing<br />

of the rear wheel swing arm and the longitudinal<br />

control arm.<br />

The welded monolever consists of extremely<br />

strong molded steel parts.The monolever<br />

has been structurally reinforced in the area<br />

of the spring strut support and the extruded<br />

sections.<br />

The swing arm is 612 mm long which has<br />

remained the same length in order to realize<br />

the seat position behind the rear wheel and<br />

the classical directional stability of a Cruiser.<br />

The forces of the Monolever spring strut are<br />

absorbed above the swinging arm bearing,<br />

which are distributed optimally in the tension<br />

struts of the frame triangle.<br />

The new spring strut is equipped with a single<br />

sleeve damper and the pre-load of the<br />

spring can be easily adjusted hydraulically<br />

with a hand adjustment knob.<br />

The rear wheel has 120 mm of travel. The<br />

damper system is identified as W.A.D.,<br />

which is a german acronym for travel related<br />

dampening.<br />

This principle works in the compression<br />

stroke with a needle valve that closes off a<br />

fluid dampening section within the strut to<br />

increase damping when travel movement<br />

comes close to the end limits.<br />

Technical Features in Detail<br />

17

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

The rear frame section is welded together<br />

by a combination of tubular, cast and forged<br />

steel components. The frame is then paint<br />

finish coated.<br />

Cast steel bearings for supporting the foot<br />

pegs of the rider and pillion are welded to<br />

the frame. They are attached to the engine<br />

in the area of the longitudinal control arm<br />

bearing, the oil pan and on the considerably<br />

reinforced light metal-gearbox case.<br />

18<br />

Tail Frame Section<br />

Due to the longer seat system and the addition<br />

of the top case, the rear frame is<br />

lengthened accordingly. The side cases are<br />

mounted to tubular frame extensions providing<br />

a screw mounting point.The left side<br />

extension is removable for tire service by<br />

removing four screws.<br />

Front Wheel<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

Chassis and Wheels<br />

The new die-cast aluminum wheels with<br />

their five double spokes radiate dynamic<br />

performance and are visually supported by<br />

the powerful large tires.<br />

The rear wheel measures 4.0 x 15 with tire<br />

measuring 170/80 VR 15 for good traction,<br />

high mileage and ride comfort.<br />

The wheel is screwed directly to the rear<br />

axle with four wheel-bolts enabling the<br />

wheel to be removed easily once the side<br />

case is removed or with a service lift with a<br />

removable floor.<br />

The front wheel measures 3.5 x 16 with tire<br />

measuring 150/80 VR 16 for the best braking<br />

efficiency and comfort. The front wheel<br />

axle is also new. It’s length has been<br />

increased due to the wider spacing.<br />

Removal of the rear wheel is simplified by<br />

the use of the accessory service stand jack<br />

and a detachable rear frame that is accessible<br />

from behind the left side saddle bag.<br />

The rear wheel can be removed without<br />

removing the side frame if the motorcycle is<br />

on a service lift with a removal rear wheel<br />

floor.<br />

• Detach the case 2 x T25 + 2 x T30<br />

• Case mount (frame section) 4 x T40<br />

• Rear wheel bolt 4 x M12 x 60.<br />

• Note the intermediate spacer.<br />

Technical Features in Detail<br />

Front & Rear Wheels<br />

Frame Case Mount Removal/Installation<br />

Spacer Plate<br />

Rear Wheel Removal/Installation<br />

4 x T20<br />

Torque<br />

to 20 Nm<br />

when reinstalling<br />

105 Nm<br />

(cross pattern)<br />

19

R <strong>1200</strong> <strong>CL</strong><br />

Brake Components and Integral ABS<br />

The brake system has been designed to<br />

meet the demands of a touring Cruiser. The<br />

EVO brake and fully integral ABS are used<br />

for the first time on the R <strong>1200</strong> C model.<br />

The large 305mm floating brake discs made<br />

of high-grade steel are used on the front<br />

wheel. The bearings are connected directly<br />

to the hub of the front wheel by means of a<br />

secondary support and five screws. Drilled<br />

discs enhance the brake reaction in wet<br />

conditions and increase the self-cleaning<br />

effect.<br />

The two hydraulically operated 4-piston<br />

calipers are designed as fixed calipers providing<br />

angular wear compensation due to<br />

the offset piston diameters. The piston<br />

diameters are 36 or 32 mm.<br />

20<br />

The sintered metal brake pads have a brake<br />

pad surface of 86 cm 2 .The rear wheel brake<br />

is a hydraulically operated single disc brake<br />

with 4-piston caliper and organic brake<br />

pads. It has been taken over essentially<br />

from the K <strong>1200</strong> LT model.<br />

The floating high-grade steel brake disc<br />

screwed to the ring gear of the rear axle has<br />

retained the diameter of 285 mm. The thickness<br />

of the disc has been increased to 7 mm.<br />

A visual wear indicator is mounted on the<br />

steel support of the outer brake pad to<br />

make it easy to check the available pad<br />

thickness as the brakes where and as an<br />

indicator that they require replacement.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Brake Components and Integral ABS<br />

Technical Features in Detail<br />

New!<br />

Brake Pad Wear Indicator<br />

When the tab of the indicator<br />

touches the pad on the other<br />

side, replace the pads.<br />

21

R <strong>1200</strong> <strong>CL</strong><br />

Brake Components and Integral ABS<br />

The BMW fully integral ABS enables the<br />

braking efficiency to be distributed via electronic<br />

control ensuring optimal braking<br />

power is always available on each wheel. At<br />

the same time, influencing factors such as<br />

dynamic wheel load distribution, load and<br />

temperature of the brakes are taken into<br />

account. In addition, the system includes<br />

the antilock function so that a reliable braking<br />

function is available on the motorcycle.<br />

The system’s integrated brake booster<br />

keeps the operating force of the brake lever<br />

low for the rider. With the fully integral variant,<br />

the front and rear control circuits are<br />

connected by integral pistons in the pressure<br />

modulator that the front and rear wheel<br />

brakes are activated automatically when the<br />

hand lever or rear pedal are operated.<br />

22<br />

The fully integral pressure modulator of the<br />

R <strong>1200</strong> <strong>CL</strong> is installed beneath the tank.The<br />

brake fluid reservoirs for the front and rear<br />

wheel circuit are located in the pressure<br />

modulator as on all R series bikes. The<br />

brake fluid reservoir for the front control circuit<br />

is located in the hand lever master<br />

cylinder. The rear control circuit reservoir is<br />

connected to the brake pedal master cylinder<br />

via a feed line (green line in illustration).<br />

As with all versions of the Integral ABS, the<br />

modulator control valves are designed to<br />

provide the residual braking function, which<br />

connects the control circuits and wheel circuits<br />

via piston movement (hydraulic over<br />

hydraulic control). This safety feature<br />

ensures adequate brake function if the ignition<br />

is turned off or if the Integral ABS is<br />

defective.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Brake Components and Integral ABS<br />

The other lines run as follows:<br />

• The orange line (actuating pressure) and<br />

the yellow line (brake actuator signal) run<br />

from the handbrake lever to the pressure<br />

modulator.<br />

• The orange line (actuating pressure) and<br />

the yellow line (brake actuator signal) run<br />

from the foot brake lever to the pressure<br />

modulator. Furthermore, the green line<br />

comes from the brake fluid reservoir to<br />

the foot brake cylinder.<br />

• The red lines run from the pressure modulator<br />

(wheel circuit) to the front wheel<br />

and rear wheel brake calipers.<br />

• The sensor signals (blue) come from the<br />

front and rear wheel to the controller.<br />

• The warning lights in the cockpit are controlled<br />

via the blue lines.<br />

Technical Features in Detail<br />

The new light weight speed sensor trigger<br />

rings in combination with the active wheel<br />

speed sensors recognize wheel locking<br />

tendencies much faster than the previous<br />

analog inductive sensors.<br />

The speed sensor signals are input to the<br />

Integral ABS control module for continual<br />

processing and are also output to provide a<br />

speedometer signal for systems requiring<br />

accurate speed information such as the<br />

cruise control and speedometer.<br />

The system also monitors the function of<br />

the brake light and rear light and indicates<br />

their failure when necessary. If a rear light is<br />

defective, the dimmed brake light takes over<br />

its function.<br />

The general warning light and an ABS warning<br />

light are located in the cockpit for indicating<br />

possible defects or faults.<br />

23

R <strong>1200</strong> <strong>CL</strong><br />

Bodywork<br />

The front fairing integrated headlights<br />

give this motorcycle a very distinctive<br />

visual appeal.<br />

The fairing integrated mirrors (which also<br />

house the direction indicator lights), and the<br />

permanently fixed windshield, the 3-part<br />

fairing harmoniously combines Cruiser and<br />

tourer features, providing a new standard for<br />

luxury cruising.<br />

The tank and side trim panel parts are distinctive<br />

with the ergonomics of the knee<br />

angle and the aerodynamically optimized air<br />

outlets of the oil coolers which provide<br />

additional leg protection.<br />

24<br />

These combined features result in a casual,<br />

pleasant seating position, the anatomy of<br />

the knee angle being particularly distinguished<br />

in the area of the air filter cover. The<br />

painted wide rear fender emphasizes the<br />

bikes stretched lines.<br />

The front fairing attached to the handlebars<br />

protects effectively against disturbing wind<br />

pressure and turbulence. Transparent wind<br />

guide vanes attached to the fairing ensure<br />

that additional water and dirt is deflected<br />

mainly from the passenger.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Bodywork<br />

There are two windshield versions; low and<br />

high.The US market will receive the low version<br />

as standard equipment. The high version<br />

can be purchased as an accessory.<br />

Both types are distinctive thanks to their<br />

functional design, which is cut lower in a<br />

curved arch in the rider’s field of vision.<br />

Technical Features in Detail<br />

The advantage is not only an enhanced field<br />

of vision in wet and dusty conditions. But at<br />

high speeds in particular, the ingenious<br />

recess improves the protection in the area<br />

of the shoulder and provides added wind<br />

protection for the passenger.<br />

25

R <strong>1200</strong> <strong>CL</strong><br />

Bodywork<br />

The mirror housings are designed as aerodynamic<br />

hand protectors. They are ventilated<br />

at the rear in order to prevent turbulence<br />

from forming on the handlebar grips. The<br />

rear-view mirrors can be quickly removed<br />

from the fairing by means ball sockets (ie: K<br />

<strong>1200</strong> LT, R 1150 RT).<br />

The fuel tank trim panels protect the rider’s<br />

legs against the air stream and have integrated<br />

rain deflectors built in by design<br />

(edges flair outward).<br />

The panels are hollow plastic covers that<br />

attach to sheet steel carriers by screws.<br />

The space between the colored covers and<br />

steel carries houses a portion of the motorcycles<br />

electronic equipment (left side:<br />

optional Anti Theft System, right side: cruise<br />

control module). The side trim panels do<br />

not have to be removed if the fuel tank is<br />

removed.<br />

The handlebars are made from a 3.5 mm<br />

thick steel tube and have a diameter of<br />

28mm. The surface is coated with hard<br />

chrome. Handlebar weights are fitted at the<br />

ends of the handlebars for damping vibration.<br />

Perfect seating comfort includes the feet<br />

too: Running boards made of forged aluminum<br />

and vibration decoupled for the rider<br />

by rubber bearings and wide passenger<br />

foot rests derived from the K <strong>1200</strong> LT guarantee<br />

good foothold, and combined with<br />

the pleasant knee angle, ensure relaxed riding.<br />

26<br />

The seats include optional heating elements<br />

(standard on the <strong>CL</strong>C). The boldly<br />

designed border of the upper passenger<br />

supporting straps makes the luggage<br />

bridge a real eye catcher.<br />

A special feature of the side cases is the<br />

one-hand closing concept. After pressing<br />

the lock cylinder in, the flush finger lift lever<br />

springs up to unlatch the cover. When<br />

closed, the case cover latching system<br />

evenly compresses the lid into the seal by<br />

four integrated tension rods.<br />

A same key lock set is equipped with the<br />

motorcycle allowing a single key to operate<br />

the ignition lock/steering lock, filler cap and<br />

luggage system.<br />

The luggage system is integrated into the<br />

overall appearance of the R <strong>1200</strong> <strong>CL</strong>. The<br />

top case with a volume of 45 litres providing<br />

plenty of space for luggage.The central<br />

handle easily operates the latch and locking<br />

system as on the K <strong>1200</strong> LT. The combined<br />

side case volume of approximately 63 litres<br />

brings the total lockable storage capacity of<br />

the R <strong>1200</strong> <strong>CL</strong> to 108 litres.<br />

Case Capacities:<br />

Top Case = 45 liter (1.59 cu ft)<br />

Left Case = 33 liters (1.16 cu ft)<br />

Right Case = 30 liters (1.06 cu ft)<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Bodywork<br />

Technical Features in Detail<br />

27

R <strong>1200</strong> <strong>CL</strong><br />

Headlights<br />

The four round headlights have been integrated<br />

in a new arrangement never before<br />

used on a BMW Motorcycle. The headlamps<br />

are mounted to an adjustable support<br />

made of a synthetic material.<br />

They consist of two larger low beam headlights<br />

and two smaller high beam headlights<br />

positioned one on top of the other.<br />

The low beam headlights work with an H4light<br />

and can be readjusted from the front.<br />

The high beam headlights with H1-lights<br />

enable wide illumination of the road with<br />

their scattered light.<br />

The park lamps with 4-watt conventional<br />

bulbs are installed in the low beam headlights.<br />

All electric light bulbs can be<br />

replaced from the outside after removing<br />

each inner trim.<br />

28<br />

The beam distance can be adjusted to<br />

compensate for two up riding with the<br />

spring-loaded lever located on left side of<br />

fairing rear surface. For normal position,<br />

lever is up, to adjust flip down (as shown).<br />

Load compensation light beam adjustment lever<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Headlights<br />

Lever Positions:<br />

Horizontal: normal position (shown); Always<br />

adjust base setting of headlights with lever<br />

in this position.<br />

Flipped down: position for 2 up with luggage<br />

(shown on previous page).<br />

The adjustment screw found in the center of<br />

the load adjustment lever is used to establish<br />

the base headlight position of the total<br />

headlamp assembly. This screw simultaneously<br />

adjusts the vertical position of all four<br />

headlights.<br />

R <strong>1200</strong> <strong>CL</strong> Introduction<br />

Base setting adjustment screw<br />

29

R <strong>1200</strong> <strong>CL</strong><br />

Cockpit and Instruments<br />

The central component in the cockpit is the<br />

instrument cluster with its three round<br />

gauges and the centrally located ignition<br />

lock.<br />

The instruments are housed in an aluminum<br />

cockpit-support that is mounted on the fork<br />

brace. The cover glass and functionally<br />

designed analog instruments feature<br />

chrome rings. The electronic tachometer is<br />

large and easily read. The analog clock, is<br />

mounted high and centered always in the<br />

rider’s field of vision. The time can be<br />

adjusted easily by using the large rubber<br />

pushbutton located on the right hand side<br />

of the clock.<br />

The speedometer’s integrated digital LCD<br />

display includes a mileage meter that can<br />

be reset with the left reset button. The<br />

mileage indicator retains the setting selected<br />

prior to switching off the ignition, i.e.<br />

odometer or trip meter.<br />

30<br />

The warning lamps and signal indicators in<br />

the three centrally located rows are LEDs.<br />

• Top: green turn signals, red engine oil<br />

pressure and battery charge indicators.<br />

• Middle: Two red ABS, green neutral and<br />

round red Anti Theft<br />

• Bottom: Yellow reserve fuel indicator that<br />

flashes when the level reaches 4 liters, a<br />

blue high beam and the yellow cruise<br />

control indicators<br />

The clutch and brake levers are adjustable<br />

in order to ensure better ergonomics.There<br />

is a two stage heated-grip flip switch (50<br />

and 100%) on the right side combination<br />

switch.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Electrical Components<br />

3<br />

11<br />

The neatly arranged electrical system is<br />

located under the fuel tank and is the<br />

basis for operating the electrical components.<br />

In addition to the distribution system<br />

technology and high quality connectors,<br />

the new wiring harness provides the<br />

possibility of options such as the Anti<br />

Theft System to simply plug into wiring<br />

provisions.<br />

The Motronic control module is located<br />

above the central electrical control box.<br />

Different electrical accessories can be connected<br />

to the wiring harness via the preinstalled<br />

special accessory-terminal.<br />

The electronic speedometer is supplied<br />

with a processed speed signal from the<br />

Integral ABS control module.The turn signal<br />

indicator relay is also fed with the speed<br />

signal, which ensures that the direction<br />

indicator is reset after approx. 210 m and/or<br />

11 seconds.<br />

Technical Features in Detail<br />

4<br />

1<br />

5<br />

2<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Electrical components:<br />

1 Blinker/Flasher module<br />

2 Fuel level indicator<br />

dampening module<br />

3 High beam relay (yellow)<br />

4 Starter relay<br />

5 Low beam relay (yellow)<br />

6 ABS warning relay<br />

7 Motronic relay<br />

8 Fuel pump relay<br />

9 Horn relay<br />

10 Load Shed Relay<br />

11Terminal connection for<br />

Ignition and light switch<br />

Not pictured - located<br />

under starter relay is<br />

starting system diode<br />

The light-emitting diode for the reserve fuel<br />

is controlled via an electronic module,<br />

which has a time delay of 17 seconds.<br />

The alternator’s maximum output is 840<br />

Watt, of which 300 watts is available at<br />

engine idle speed.The compact battery has<br />

a capacity of 19 Ah.<br />

Cranking the engine is accomplished with<br />

an 1.1-kW planetary gear starter. Cranking is<br />

only possible when the gear box is in neutral<br />

or in gear with the clutch lever pulled in.<br />

Only then is there voltage on the coil of the<br />

ignition relay via the clutch lever and gear<br />

lever. Starting is only possible after the prop<br />

stand has been folded in. This is a typical<br />

safety feature of BMW. If a gear change is<br />

made when the side prop is folded out, then<br />

the Motronic relay is switched off.<br />

Two easily accessible fuse boxes with new<br />

mini fuses are arranged behind the left air<br />

filter cover.<br />

31

R <strong>1200</strong> <strong>CL</strong><br />

Cruise Control<br />

With the introduction of the R <strong>1200</strong> <strong>CL</strong>,<br />

cruise control is equipped for the first<br />

time on a BMW boxer. It is ideally suited<br />

for a luxury Cruiser, because it allows<br />

particularly relaxed riding both on interstates<br />

as well as secondary roads.<br />

The system electronics is carry over from<br />

the K <strong>1200</strong> LT. It is operated from the left<br />

combination switch. The system is turned<br />

on with the slide switch which also unlocks<br />

Set/ Resume pushbutton.<br />

A function light in the left combination<br />

switch also indicates that the system is<br />

ready. The SET LED in the central indicator<br />

display signals to the rider that the cruise<br />

control is activated.<br />

By pressing the pushbutton key in the forward<br />

direction, the current speed is stored<br />

in the control unit and kept adjusted to the<br />

accelerator cable by the cruise control.This<br />

is approx. 45 to 145 Km/h, which corresponds<br />

to 2/3 of the throttle valve opening.<br />

This is reset in the control unit by a stepper<br />

motor via an electromagnetic clutch and roll<br />

band. Thus, a fine adjustment of the speed<br />

is also possible.<br />

32<br />

This is done in intervals of approx. 1.6 km/h<br />

by tipping the pushbutton.<br />

• In the direction of SET: accelerate<br />

• In the direction of RES: decelerate<br />

If the SET function is deactivated, the last<br />

speed saved in the controller can be<br />

retrieved and set by pressing the pushbutton<br />

key in the direction of RES.<br />

The following operations cause the electromagnetic<br />

clutch to be switched off immediately<br />

thereby deactivating the cruise control:<br />

• Operating the brake or clutch<br />

• Turning back the throttle twist grip<br />

• Accelerating to more than 160 km/h<br />

• Setting the slide switch to OFF<br />

Cruise Control System Test: The cruise<br />

control system does not have a fault code<br />

memory. It does however convey functional<br />

confirmation through control of the SET<br />

indicator in the instrument cluster. This is<br />

known as the Cruise Control Self Test which<br />

can be done via MoDiTeC or by following<br />

the stand alone test on next page.<br />

When the SET indicator fails to change status<br />

in a phase of the test, it indicates a circuit<br />

problem in that area of the system.<br />

Refer to wiring diagram and check circuit(s)<br />

and components of circuit.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

1. With the ignition in the OFF position<br />

switch the cruise control switch to ON.<br />

Press and hold the cruise control button<br />

in the SET position and turn the ignition<br />

switch to ON. SET indicator goes ON.<br />

When you release the button the SET<br />

Indicator in the cluster goes OFF.<br />

2. Press and hold the cruise control button<br />

in the RESET position. SET indicator ON.<br />

Release button, SET indicator goes OFF.<br />

3. Switch the cruise control switch to OFF<br />

position. SET indicator goes ON.<br />

4. Switch the cruise control switch back to<br />

ON. SET indicator in the cluster goes OFF.<br />

5.Twist throttle grip back against detent<br />

until you feel click of microswitch. SET<br />

indicator goes ON. Release throttle grip.<br />

SET indicator in the cluster goes OFF.<br />

Technical Features in Detail<br />

6. Pull clutch lever in fully. SET Indicator in<br />

cluster goes ON. Release, goes OFF.<br />

7. Pull front brake lever. SET indicator in<br />

cluster goes ON. Release, goes OFF.<br />

8. Repeat Step 7, but hold for 5 seconds<br />

until the SET indicator automatically goes<br />

OFF. Then release brake lever and remove<br />

hand from throttle.<br />

9. Once brake is released, the cruise control<br />

module activates the motor. Listen for<br />

a click.<br />

10. Rotate the rear wheel to generate a<br />

speed signal; SET indicator in cluster<br />

blinks Flashes ON and OFF. (Roll motorcycle<br />

on shop floor)<br />

Switch Ignition OFF, end of Test.<br />

33

R <strong>1200</strong> <strong>CL</strong><br />

Cruise Control<br />

The R <strong>1200</strong> <strong>CL</strong> uses a new cable control<br />

box to converge the operation of the throttle<br />

from either the opener/closer cables of<br />

the throttle grip or the control cable from<br />

the cruise control actuator.<br />

The box is located behind the fairing and<br />

headlight assembly both of which require<br />

removal to access. The box interconnects<br />

four cables with two pulleys. It also contains<br />

a microswitch that signals the cruise<br />

control module when the throttle is turned<br />

in the close direction to cancel cruise function<br />

The spring tensioned pulleys rotate on a<br />

shared axis. The lower pulley is attached to<br />

the opener cable, the closer cable and the<br />

throttle cable. The upper pulley is connected<br />

to the cruise control cable.<br />

The pulleys rotate freely from one another<br />

when the throttle is operated from the grip.<br />

In this function, the twist grip pulls the<br />

opener cable which simultaneously pulls<br />

the throttle cable at the lower pulley.<br />

When the cruise control actuator pulls the<br />

cruise cable, the upper pulley rotates. A pin<br />

on the upper pulley engages the lower pulley<br />

and simultaneously operates the throttle.<br />

The pin on the upper pulley and the slot on<br />

the lower pulley are keyed to allow full grip<br />

control to over ride the cruise control function.<br />

When the twist grip is turned in the<br />

opposite direction the closer cable is tensioned<br />

which activates the closer switch,<br />

signalling the cruise control to deactivate if<br />

currently active.<br />

There are four adjustment points on the<br />

cables to adjust cable play. They are at the<br />

twist grip and at the cable unions under the<br />

fairing just forward of the spring damper.<br />

34<br />

Closer cable<br />

Cruise cable<br />

Cable box location<br />

Cable Box internal view<br />

Opener cable<br />

Cable Box<br />

Throttle cable<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

Cruise Control<br />

Technical Features in Detail<br />

35

R <strong>1200</strong> <strong>CL</strong><br />

Sound and Communication System<br />

The R <strong>1200</strong> <strong>CL</strong>C is equipped with the Stereo<br />

Radio with Single Player CD as standard<br />

equipment. The Base R <strong>1200</strong> <strong>CL</strong> is prewired<br />

to accept the equipment as an accessory.<br />

The system consists of the combined radio<br />

electronics/single CD player located in the<br />

right side case, the radio controller on the<br />

left hand handlebar, and the centrally mounted<br />

display/control panel. The radio unit with<br />

RDS and a scan-function.<br />

The output stages for the loudspeakers can<br />

be controlled separately, enabling the sound<br />

to be distributed individually via the balance<br />

and fader.<br />

The two standard 20-watt loudspeaker units<br />

each consist of a broad-band loudspeaker.<br />

With regard to the best sound quality, these<br />

are contained in enclosed boxes with the<br />

same volume.<br />

36<br />

The sound system mounted on the handlebar<br />

clamp in the rider’s field of vision can be<br />

switched on and off in the central control<br />

panel with a digital display.<br />

All functions are selected via illuminated<br />

buttons. The rider can easily select the volume,<br />

radio stations, station finding, mutefunction<br />

and radio traffic service by operating<br />

the standard remote control on the left<br />

grip control.<br />

The station finding can be operated manually<br />

or automatically with two levels of sensitivity.<br />

The scan-function searches for the<br />

next station or title and plays it for ten seconds.The<br />

volume can be reduced by 20 dB<br />

with the mute-function. The CD-drive is<br />

operated electronically and can be used for<br />

normal audio CDs.<br />

Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Sound and Communication System<br />

The right side case also includes a cooling<br />

fan system for the electronics. The fan runs<br />

continuously whenever the Radio/CD is<br />

switched on. Make sure nothing obstructs<br />

the intake air grill around the fan when loading<br />

the right side case.<br />

A practical extension to the sound system<br />

is the newly developed BC-Voice (onboard<br />

communication system) available as a special<br />

accessory. The VOICE system module<br />

mounts beneath the radio, but is controlled<br />

by the radio control panel due to interconnection<br />

of the two systems.<br />

The connection terminals for the mobile<br />

telephone and radio are also inserted into<br />

the front panel of the BC-VOICE.<br />

Telephone calls can be received if the<br />

device has an automatic call receiver and if<br />

a small mobile radio telephone antenna is<br />

used. The radio connection is intended for<br />

Family Radio Band (Free Talk) two way<br />

radios.<br />

Look for accessory installation instructions<br />

for the BC VOICE system on MTAS.<br />

A new easily detachable dielectric rod<br />

antenna and base union are being introduced<br />

on the R <strong>1200</strong> <strong>CL</strong>. This new style<br />

union offers simplified removal and reinstallation<br />

when necessary for cover use.<br />

The antenna is decoupled from the base<br />

using an special tool found in the tool kit<br />

and unscrewing the union. The contact is<br />

more robust than previous antennas ensuring<br />

proper connection everytime.<br />

Technical Features in Detail<br />

BC VOICE installed position / Cooling Fan<br />

Dieletric Antenna<br />

37

R <strong>1200</strong> <strong>CL</strong><br />

Technical Data<br />

Engine:<br />

Performance<br />

Max. torque<br />

Bore<br />

Stroke<br />

Effective capacity<br />

Stroke/bore ratio<br />

Compression ratio<br />

Fuel<br />

Angle of valve in relation to the cylinder axis<br />

Valve diameter Intake:<br />

Exhaust:<br />

Camshaft<br />

Valve timing at 3 mm valve play<br />

Valve stroke (without valve play)<br />

Engine oil volume<br />

Oil filter<br />

Oil pumps<br />

Lubricating Circuit Oil Pressure<br />

Engine cooling:<br />

Flow rate of the pump<br />

Start of opening of the thermostat valve<br />

Air/oil-cooled 2-cylinder 4-stroke boxer<br />

engine with four rocker arm operated<br />

valves, each with overhead camshaft and<br />

wet lubrication with two oil coolers<br />

45 kW (61 hp) @ 5000 rpm<br />

98 Nm (71 ft/lb) @ 3000 rpm<br />

101 mm (3.98”)<br />

73 mm (2.87”)<br />

1170 cm 3 (71.4 cubic inches)<br />

0.72<br />

10.0 : 1<br />

Unleaded regular grade fuel, 95 RON<br />

Intake: 19°<br />

Exhaust: 22°<br />

34 mm (1.34”)<br />

29 mm (1.14”)<br />

256°<br />

Intake opens 17° ATDC<br />

Intake closes 15° ATDC<br />

Exhaust opens 15° BTDC<br />

Exhaust closes 17° BTDC<br />

8.23 mm (0.32”)<br />

3.75 liter (4 quarts)<br />

External filter cartridge<br />

2 Troichoid pumps from auxiliary shaft<br />

driven by a chain<br />

3.5–6.0 bar (50-87 psi)<br />

at 80° C (176 O F) oil temperature<br />

Combined air/oil cooling with twin coolers<br />

integrated in the frame. Circulation by<br />

means of separate oil pumps<br />

with thermostat control<br />

35 liters (37 qts) per minute<br />

95 °C (203 O F)<br />

38 Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Technical Data<br />

Clutch:<br />

Clutch disc diameter<br />

Master cylinder piston diameter<br />

Slave cylinder piston diameter<br />

Gearbox:<br />

Primary input shaft gear reduction<br />

Gear Ratios<br />

Rear wheel drive:<br />

Transmission<br />

Ring/Pinion teeth<br />

Mixture control/ignition system:<br />

Maximum engine speed<br />

Idle speed<br />

Lambda control<br />

Fuel cut-off<br />

Fuel pressure<br />

Capacity of the fuel tank<br />

Ignition angle range (motronic controlled)<br />

Spark plug<br />

Generator:<br />

Maximum power<br />

Voltage<br />

Transmission<br />

Starter:<br />

Power<br />

Transmission of planetary gear<br />

Technical Features in Detail<br />

Hydraulically operated single-disc dry<br />

clutch with transmission disc spring and<br />

asbestos-free friction lining<br />

165 mm (6.5”)<br />

13 mm (0.5”)<br />

24 mm (0.94”)<br />

Constant mesh 6-speed transmission<br />

integrated in flange-mounted case<br />

1:1.889<br />

1st gear: 1 : 2.038<br />

2nd gear: 1 : 1.600<br />

3rd gear: 1 : 1.267<br />

4th gear: 1 : 1.034<br />

5th gear: 1 : 0.903<br />

6th gear: 1 : 0.698<br />

Angular gear with Palloid tooth system<br />

1 : 2.62<br />

34/13<br />

Digital motor electronics: Motronic MA 2.4<br />

7000 rpm (disabling of the injection signal)<br />

900 rpm<br />

Engine temperature above 60° C (140 O F)<br />

Speed above 1800 rpm<br />

Engine temperature above 70 °C (158 O F)<br />

3.0 bar (43.5 psi)<br />

17.5 liters (4.62 gallons), including approximate<br />

4 liter (1 gallon) reserve (light on)<br />

+43° to 0° OT (characteristic zone)<br />

Bosch FR6 DDC<br />

Alternator with voltage control<br />

840 W<br />

14 V<br />

1 : 1.5<br />

With magneto-electrically excited electromotor,<br />

drives the clutch plate by means of<br />

intermediate gearbox and pre-engaged<br />

drive<br />

1.1 kW (1.5 hp)<br />

1: 5.5<br />

39

R <strong>1200</strong> <strong>CL</strong><br />

Technical Data<br />

Front wheel suspension:<br />

Full spring travel on the wheel<br />

Stanchion diameter<br />

Steering lock angle<br />

Spring/Dampening<br />

Rear wheel suspension:<br />

Effective length of swing-arm<br />

Spring deflection on the wheel<br />

Damping system<br />

Wheels:<br />

Dimensions<br />

Tires:<br />

Dimensions<br />

Brake system:<br />

Front:<br />

Brake disc diameter<br />

Brake disc thickness<br />

Caliper piston diameters<br />

Master cylinder piston diameter<br />

Brake pad friction material<br />

Rear:<br />

Brake disc diameter<br />

Brake disc thickness<br />

Caliper piston diameters<br />

Master cylinder piston diameter<br />

Brake pad friction material<br />

Telelever with central strut and tilt decoupling<br />

of the upper fork brace<br />

144 mm (5.67”)<br />

35 mm (1.38”)<br />

35 ° right / left<br />

Strut with coil spring and twin-sleeve<br />

damper (non adjustable)<br />

Monolever with central strut, Steel swing<br />

arm and single-sleeve damper Spring preload<br />

adjustable hydraulically<br />

612 mm (24”)<br />

120 mm (4.72)<br />

WAD (Travel related damping on the compression<br />

stroke)<br />

Die-cast aluminum wheel, 5 double spokes<br />

Front: 3.50"x16" MTH2<br />

Rear: 4.00"x15" MTH2<br />

Light low-section Cruiser tire<br />

Front: 150/80 VR 16<br />

Rear: 170/80 VR 15<br />

Hydraulically operated, Standard I-ABS<br />

Double-disc brake with 4-piston fixed<br />

caliper, de-skew, floating high-grade steel<br />

brake discs<br />

305 mm (12.0”)<br />

5 mm (0.2”)<br />

32/36 mm<br />

16 mm (0.63”)<br />

Sintered metal<br />

4-piston fixed caliper, floating high-grade<br />

steel brake disc with asymmetrical bearings<br />

285 mm (11.2”)<br />

7 mm (0.27”)<br />

32/34 mm<br />

14.29 mm (0.56”)<br />

Semi-metal (organic)<br />

40 Technical Features in Detail

R <strong>1200</strong> <strong>CL</strong><br />

Technical Data<br />

Dimensions:<br />

Overall length<br />

Width at the rear view mirrors<br />

Height at the top edge of the windshield<br />

Wheelbase in normal position<br />

Trail in normal position<br />

Steering head angle in normal position<br />

Seat height, unladen weight<br />

laden weight (187 lb rider)<br />

Ground clearance in normal position<br />

Weights:<br />

Unladen, road ready and fully fueled<br />

Permitted total weight (GAVR)<br />

Performance:<br />

Maximum speed<br />

Acceleration 0–100 km/h (0-62 MPH)<br />

Average fuel consumption for one hour of<br />

riding at a constant:<br />

• 90 km/h (55.9 mph)<br />

• 120 km/h (75.0 mph)<br />

Technical Features in Detail<br />

2,415 mm (95.0” - or - 7.92’)<br />

1,075 mm (42.3”)<br />

1,435 mm (56.4”)<br />

1,641 mm (64.6”)<br />

184 mm (7.24”)<br />

56.5°<br />

755 mm (29.7”)<br />

745 mm (29.3”)<br />

159 mm (6.25”)<br />

308 kg (679.0 lbs) standard equipment<br />

530 kg (1,168.5 lbs)<br />

allows max rider, passenger and luggage<br />

weight of 222 kg (489.5 lbs)<br />

165 km/h (102.5 mph)<br />

6.3 s<br />

5.1 liters (1.34 gallons)<br />

6.2 liters (1.64 gallons)<br />

41

R <strong>1200</strong> <strong>CL</strong><br />

PDI Procedures - Uncrating<br />

Delivery and Crate Inspection<br />

While the motorcycle is being unloaded by the shipper, thoroughly inspect the<br />

crate for damage. Department of Transportation law requires the driver to allow<br />

you, the representative of your dealership ample time to perform a thoroughly<br />

crate inspection for each delivered unit.<br />

Maintain your familiarity of motorcycle delivery receipt, inspection and claims<br />

processing by reviewing the following official BMW Motorcycle documents:<br />

• Motorcycle Transportation Damage Policies and Procedures. This document<br />

is available on MTAS (Service>Warranty Information).<br />

• Motorcycle Service Information Bulletins, Group 4 (Warranty).<br />

If any crate damaged is present:<br />

• Thoroughly examine the motorcycle and all contents for consequential damage<br />

or missing parts.<br />

• Clearly note damage and or missing parts on the truckers bill of lading (delivery<br />

slip).<br />

• Inform the trucking company in writing without delay.<br />

• Damage under $750.00 must be claimed via warranty.<br />

• Damage over $750.00 requires your field representative to be contacted. The<br />

field representative must authorize your claim prior to submittal.<br />

Crate Contents/Locations<br />

• Front Wheel • Key set (D)<br />

• Windshield (A) • Antenna (C)<br />

• Fender (B) • Mirrors (E)<br />

• Rider Manuals, Dealer Directory (I)<br />

• Pertinent attaching hardware (F)<br />

• Tool Kit (F)<br />

• Top Case (G)<br />

Start a Vehicle History File<br />

• Establish a Vehicle History File.<br />

• Remove the documentation on the<br />

side of the crate and place it into<br />

the file.<br />

42<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

PDI Procedures - Uncrating<br />

R <strong>1200</strong> <strong>CL</strong> Introduction<br />

43

R <strong>1200</strong> <strong>CL</strong><br />

PDI Procedures - Uncrating<br />

Lever off top cover and minimize for easy handling<br />

44<br />

Remove top plastic bag<br />

Carefully lever out top supports<br />

Uncrating the motorcycle<br />

• With the crate on a level surface,<br />

remove the top cover by levering it<br />

off with a pry bar.<br />

Hint: Place the crate top on the<br />

edge of the crate frame and snap it<br />

in half. This will make handling the<br />

cover more manageable.<br />

• Remove the plastic bag suspended<br />

between the crate lateral supports.<br />

Set the bag aside in a safe place.<br />

• Remove the antenna from right side<br />

crate support.<br />

• Pry or cut the lateral supports out<br />

from the top of the crate as shown.<br />

• Using a suitable saw such as a<br />

reciprocating saw (Sawzall TM ), carefully<br />

cut the sides of the crate<br />

where they attached to the end<br />

panels.<br />

• Do this on both sides of the crate<br />

(total of 8 cuts).<br />

Cut crate in 8 locations as shown (both sides)<br />

R <strong>1200</strong> <strong>CL</strong> Introduction

R <strong>1200</strong> <strong>CL</strong><br />

PDI Procedures - Uncrating<br />

Note: During next three steps, ensure crate panels do not damage motorcycle.<br />

• Remove the front tire from the right side area of the crate and set it aside.<br />

• Remove both side panels from the crate base by carefully pivoting forward<br />

and backward until vertical brace detaches from base.You may also choose<br />

to cut the vertical braces at the bottom with someone assisting you.<br />

• Remove both crate end panels by forcibly pulling the panels from the crate<br />

base. Give a good yank, they will separate from the crate base quite easily.<br />

• Critical Step! Wipe down the brake<br />

rotors on both wheels with brake<br />

cleaner and a lintless rag. Make<br />

sure you also clean the disc surfaces<br />

beneath the pads on the rear<br />

wheel as soon as you can prior to<br />

operating brakes.<br />

• Remove the front straps first. The<br />

rear straps will hold the motorcycle<br />

upright on the crate base. Hint:<br />

Configure strap loop end as shown.<br />

Grasp the loop tightly and pull it<br />

away from the buckle.<br />

• Attach tie strap to handlebar/triple<br />

clamp fittings as shown. If equipped<br />

with radio, strap on outside of fork<br />

bridge clamps only. Do not damage<br />

radio control/display panel with<br />

strap.<br />

• Use special tool 90 88 6 465 640<br />

(crane) to lift the front end off the<br />

crate base. As you raise motorcycle,<br />

loosen rear shipping straps.<br />

• Cut crate base just forward of rear<br />

wheel on both sides as shown. Slide<br />

crate forward and out from under bike.<br />

R <strong>1200</strong> <strong>CL</strong> Introduction<br />

Release Tie Down Straps Holding Bike to Base<br />

Lifting Front Axle, removing pallet and supporting<br />

45

R <strong>1200</strong> <strong>CL</strong><br />

PDI Procedures - Set Up<br />

• Clean area under motorcycle completely<br />

ensuring any sharp objects<br />

or nails are removed.<br />

• Install fender. Unbolt the calipers<br />

from the front forks.<br />

• Loosen fork leg pinch bolts (5 & 6).<br />

Remove axle bolt (4), axle (3), and<br />

spacer (2) from forks.<br />

• Ensure spacer seal (1) is positioned<br />

onto hub (opposite side as shown).<br />

• Coat axle lightly with Optimoly TA<br />

(Never seize). Position wheel into<br />