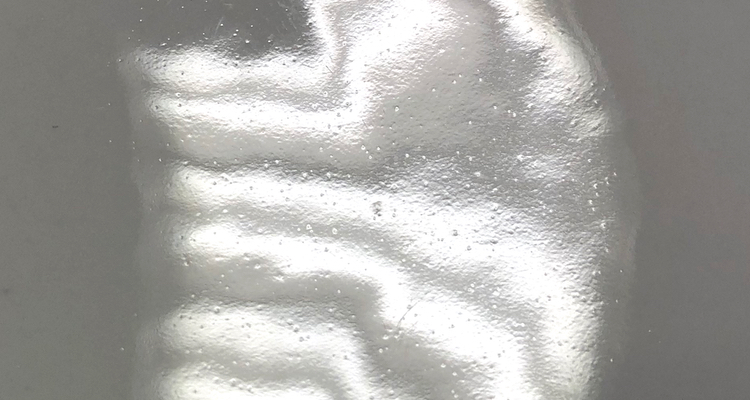

Pinholes

(Click on the picture to enlarge)

Pinholes & pinpricks in porcelain

Pinholes are not only part of the family of blemishes and are pinhead-sized, hardly visible "glaze craters", small grinding spots, air bubbles or small post-glazed fire cracks. The number of needle stitches indicates the severity of the defect. Small glaze defects in small numbers (usually 1 to 2) or minimal deformation of the body or a not quite uniform colour shade of the body, which only become visible by moving the porcelain item back and forth, are generally not considered defects in porcelain.

Such occurrences are only a defect in first choice porcelain and can be found at almost all manufacturers, especially from the quality level "commercial choice" or "commercial sorting" which is similar to a/b-grade in Asia and are quite common in the industry, especially for porcelain for HoReCa with up to 15% share. As a rule, the manufacturer rewards such tolerances with a price advantage of between 25 and 38% over the first choice. The favourable price is due to a more generous sorting.

Here is an excerpt from a post on the blog www.chefkoch.de: "...I have finally bought myself some beautiful tableware that I use in everyday life: Hutschenreuther Maria Theresia in white. It was expensive, but on offer and supposedly first choice. When you look closer you can see small bubbles. But other pieces in other shops also had this, which were also first choice and not on offer. So it was okay for me to..."

An increased number of pinpricks can lead to a decrease in mineral surface hardness. However, this can be determined by a precise laboratory analysis, and unfortunately there is no rule of thumb. The number and size of the needlesticks that lead to a reduction in surface hardness varies greatly from case to case and from dish to dish. However, we can confirm from practical experience that many dishes with a Mohs hardness of 7 (according to DIN EN-15771) can be graded to a hardness of 6 already due to a small number of pinpricks.

If one imagines that needle pricks appear as crater-like openings under the microscope, it becomes clear that in such pores and craters not only are foreign matter unnecessarily adhering to the surface, but also an additional attack surface for cuts (cut marks) and glaze corrosion is created.

Please also read our article in this product guide: "Hardness scale for porcelain & ceramics"