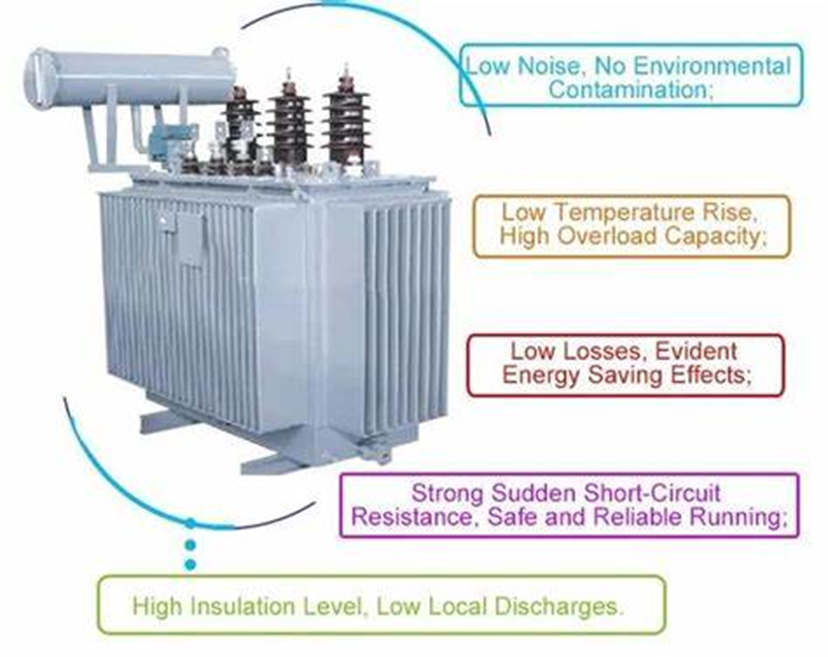

With Putuo Large Oil Immersed Distribution transformers, you obtain not only the transformer but also an Energy Partner for your business

- Excellent short-circuit resistance

- Satisfies the various load conditions required by customers

- Low-loss step lap laminated core

- Uses latest insulation material with high short-circuit strength to realize high thermal capacity

- Cold steel sheet is used for radiating pipe to ensure a sufficient cooling effect and aesthetic exterior

- Compact, light, and low-noise transformer with standard efficiency and noise level which can be easily installed even in a small indoor or outdoor area

Latest developments: Expandingthe portfolio

Putuo Electric introduces FreeCombination™Technologythat combines various types of transformer production into one united mechanism to improve production efficiency, stabilize product quality, and enhance product performance.

All these transformers can be designed, customized, and supplied with a wide variety of accessories, as required.

Putuo Large Oil Immersed Distribution transformers are able to reach 25 MVA and operating voltages of up to 40.5 kV. This product offers individual solutions for satisfying requirements related to types of operation, low noise and low losses, connection technology, type of cooling, transportation and so on.

Reliable solutions for all applications

Putuo Elecric has expertise in producing transformers for optimum space utilization, special requirements, and the most demanding conditions, has become one of the global leaders in power technologies, providing the broadest experience in all applications, ranges, and customized projects:

- Bitcoin Mine

- Semiconductor and LCD related factories

- Steel and metal plants

- Car factory

- Cement factory

- Pulp/paper mills

- Material recycling plant

- Seawater Desalination Facilities

- Flue Gas Desulphurization / Denitrification

- Wastewater Treatment Facilities

- Solid Waste Management Facilities

- Urban distribution network transformation

- Machinery manufacturing plant

Our technology: What makes us different?

Putuo Electric uses the most advanced production technologies and the most demanding control systems to guarantee the highest product quality and total product reliability.

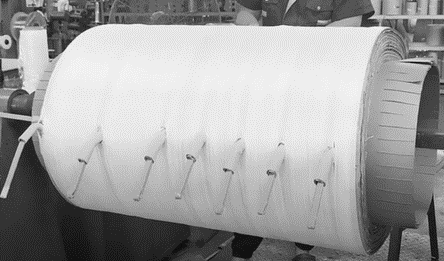

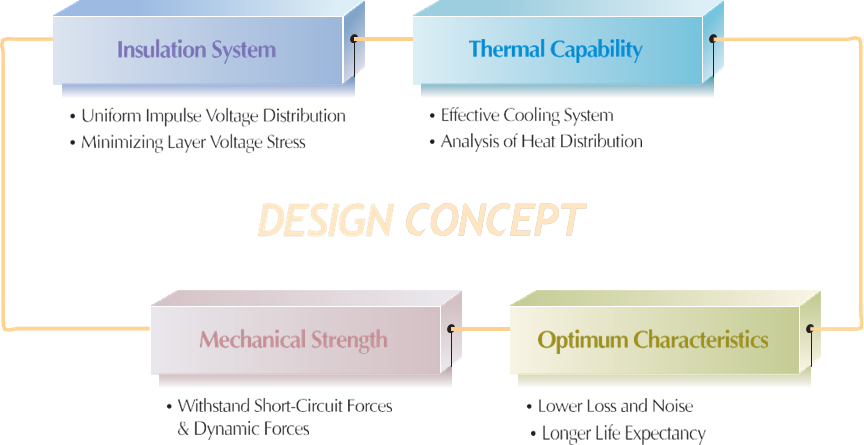

01 Windings

Windings are composed of two parts, namely, a conductor and insulation material. For the conductor, Hyosung uses high grade electrolytic copper or aluminium. Putuo Oil immersed transformers obtain high thermal capacity with the use of Epoxy coated Insuldur Kraft Paper, which has higher short time overload capacity than any other Kraft paper type.

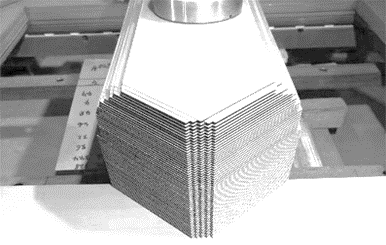

02 Core

Core design is essential because it determines the transformer’s efficiency and noise level. For high dimensional accuracy, the core cutting processing of Hyosung is controlled by a computerized system. By Step-Lap core stacking, Hyosung Oil immersed transformers attain to optimal characteristics for each customer.

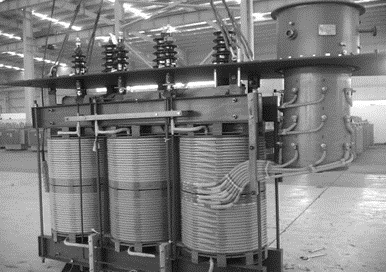

03 Winding Support System

Coils are sized and clamped by being pressed with a special hydraulic fixture after assembly with the core. With Axial and Radial direction, we reinforce the winding support system. This secure structure helps withstand harsh short circuit forces.

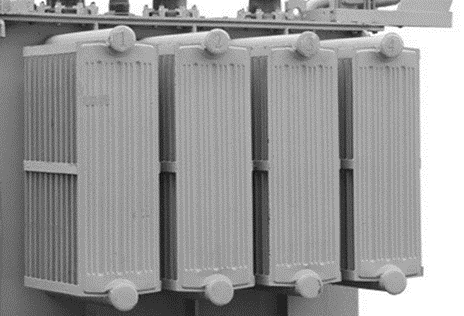

04 Radiator

The transformer will be furnished with panel or corrugated radiators assuring that the temperature rise of the windings or oil will not exceed their specified limit when the transformer continuously operates at the rated full load.

Putuo Electric manufactures various energy efficiency grades of large oil immesed Distribution transformers:

Our values: All this process is certified under the strictest quality standards

Customized solutions: Meet customer’s various demands

Design options

- Reduced loss transformers

- Low voltage transformers

- Reduced temperature rise

- Multiple primary voltage

- Multiple secondary windings

- Multi winding transformers (2, 3, 4, or 5 on the same core)

- Encapsulated low voltage windings

- Impregnated high voltage windings

- Different location of high and low voltage connection terminals: top and bottom, both on the same side

- Special connection groups

- Variable speed drives (VSD), rectifiers, and excitation transformers for 6, 12, 18, and 24 pulses

- Different coupling factors from 0.15 up to 0.9

- Earthing transformers

- Seismic and vibration reinforcement system

- Outdoor operation

- Offshore applications

- Reduced footprint

- Temperature monitor

- Antivibration pads

- Space heaters

- Painting colour

Accessories

- Fixed corrugated heat sink / removable heat sink (optional)

- Lightning arrester on high voltage bushing

- Oil temperature indicator

- Winding temperature indicator

- Oil level indicator

- Buchholz relay

- Pressure relief device

- Sudden pressure relay

- Thermometer pocket

- On load tap-changers (OLTC)

- Skid base or bi-directional rollers

- Cooling fan and fan control panel

- Various oil preservation system

- Current transformers on primary and secondary windings

- Special packings

- Hydrocoolers

- Cable boxes

- Containerized solutions

- ※ Other accessories are available upon request

Testing and logistics: Make sure every product reaches our customer with high quality

All transformers are manufactured to the most stringent quality control standards in order to guarantee the full reliability of the product

Routine test

All transformers are 100% routine tested:

• Voltage ratio measurement and check of phase displacement

• Induced over-voltage withstand test

• Partial discharge measurements

• No load loss and current measurement

• Measurements of windings resistances

• Load loss and short circuit impedance measurements

Type tests

Performed according to customer requirements:

• Temperature rise test

• Lightning impulse test

Special tests

Performed according to customer requirements:

• Measuring zero-sequence impedance

• Noise level test

• Measuring insulation resistance

• Measuring of harmonics of the no-load current

• Measuring of the parallel capacity of windings and tag ∂

• Anti-corrosion protection checking

• Short circuit test Vibration test

Logistics and services

Once the transformer is successfully tested, the product is ready for shipping, either by truck or sea freight.

As a manufacturer, Putuo Electric understands the relevance of what logistics represents to the customers. This is one of the reasons why Putuo Electric has developed a large and qualified network of suppliers with the same values and targets.

Putuo Electric takes care of all official documentation, depending on the final destination and delivery terms.

Different packaging for special applications or conditions

• Standard packaging

• Crate packaging

• Sea-worthy packaging

Putuo Electric has a long experience in arranging special transport, as and when it is required.

In addition, Putuo Electric’s global presence ensures the best, local, and after-sales service.

Working with Putuo Electric, you have access to a worldwide service with a full range of products and solutions, access to production facilities using the most up to date technologies that provides the highest quality for standard and specially made products and solutions. Our warranty provides “Life-long & 7/24” quality and service.