Mechanical engineering pioneers at Voith Turbo: Three brilliant former colleagues.

The talent of our employees is the most important driver of our success. A look at the past shows that at Voith, you can actually achieve your potential on the road, rail or water: Dr. Hermann Föttinger, Karl Scharfenberg and Ernst Schneider are three of our most brilliant former colleagues who to this day continue to make a significant contribution to the success of our company.

All three were outstanding engineers who had visionary ideas that they developed to market readiness through great perseverance and motivation and with the support of the “Maschinenbauanstalt Johann Matthäus Voith”, as Voith was called in those days. Whether Föttinger principle, Scharfenberg coupling or Voith Schneider Propeller, these inventions revolutionized the state-of-the-art at the time. To this day, they shape and continue to make a significant contribution to our Group Division Voith Turbo. And they inspire our entire team to ever new heights of engineering excellence.

Here, the three Voith pioneers tell us in their own words how they came up with their brilliant ideas that changed the world forever.

Dr. Hermann Föttinger:

The fluid whisperer.

As far back as June 24, 1905, Dr. Hermann Föttinger was awarded the patent for a “Hydraulic transmission with one or more driving and one or more driven turbine wheels to transfer power between adjacent shafts”. The engineer from the AG Vulcan-Stettin shipyard is therefore regarded as the inventor of the compact torque converter. Voith engineers from the turbine construction division had already supported Föttinger in the early days. Industry experts also recognized the huge importance of this technical innovation, which nowadays would be referred to as a “disruptive technology”. Nevertheless, the “Föttinger principle” initially sank into oblivion for over 20 years. The mechanical competition was too strong thanks to improvements in gear technology.

When, almost a quarter of a century later, the “Maschinenbauanstalt Johann Matthäus Voith” won an order to supply pumps and turbines for the Herdecke pumped storage power plant in the Ruhr area, the engineers in Heidenheim remembered the Föttinger principle. Since mechanical solutions were reaching their limits due to the specified power transmission of 36,000 HP, they focused on leveraging the benefits of a hydrodynamic coupling – and in consultation with Dr. Hermann Föttinger developed the first Voith fluid coupling. Subsequently, this new technology became so important for Voith that it gave rise to what is now the Group Division Voith Turbo.

Karl Scharfenberg:

An idea that just clicked.

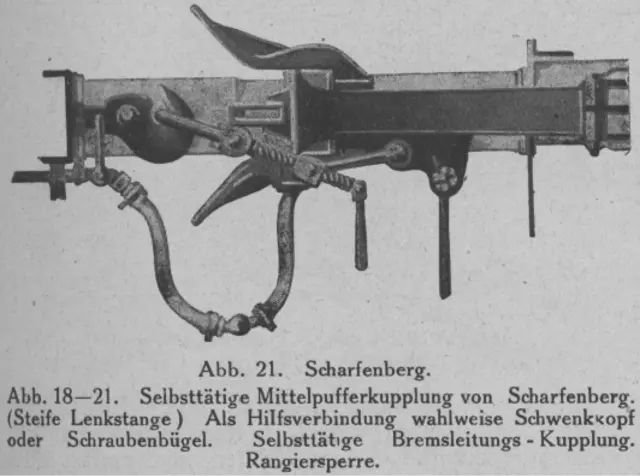

Patented in 1903 as a “central buffer coupler with hoop and rotatable draw hook as coupling elements”, the new connection for railcars becomes world-famous as the Scharfenberg coupler, known as the “Schaku” in German. Through his invention, Karl Wilhelm Heinrich Friedrich Scharfenberg solved a major problem in the rail transport industry. Thanks to the new technology, transport companies were able to connect trains automatically for the first time, without workers having to enter the dangerous area between railcars. Apart from the much improved occupational safety aspect, Voith Scharfenberg-type couplers are speeding up the assembly of trains to this day.

Thanks to the special design of the coupler head with cone and cup, Scharfenberg couplers create a rigid, form-fitting connection that reduces play to a minimum. A horizontally and vertically movable linkage enables automatic coupling even with horizontal or vertical offset, for example in bends or the crests of hills. During the coupling process, the link of one coupling hooks into the core of the mating coupling and creates a balance of forces.

Nowadays, Scharfenberg couplers from Voith are used in rail transport worldwide. CargoFlex, the automatic freight coupler developed by Voith, recently impressed across the board in tests on the use of the digital automatic coupler in European rail freight transport. And so the success story continues.

Ernst Schneider:

The vertical thinker.

What happens if a ship’s propeller doesn’t rotate horizontally in the water but vertically? This was the question that Ernst Leo Schneider was asking himself even as a student of mechanical engineering in Vienna. This caused him to delve deeply into the topic “Utilizing the forces of liquid vortices” as he describes it in his patent registration. The result, the Voith Schneider Propeller (VSP), was and still is a revolutionary maritime propulsion system that can produce thrust in all directions – and which therefore has massively improved particularly the maneuverability of ships. It consists of an impeller rotating around a vertical axis.

When Ernst Schneider discovered this principle in the 1920s and designed the first prototypes, it was met by enthusiasm and skepticism in equal measure within the industry. Together with Voith, the inventor ultimately developed the VSP into an ongoing success story worldwide. In the meantime, there is also an electrified version, the eVSP.

Thanks to the VSP, ships are able, for example, to change direction in just a few seconds at full speed, move sideways or back and forth, turn round or stay on the spot. These properties make the propulsion system indispensable for many maritime applications, today more than ever.

What’s your passion? What idea do you have up your sleeve? Or do you simply want to reinvent yourself?

Voith Turbo offers career opportunities ranging from management roles to mechanical engineering, production or IT. Whatever you want to achieve – we are ready.