Professional Documents

Culture Documents

EP1461474B1

Uploaded by

nthung1150 ratings0% found this document useful (0 votes)

4 views20 pagesPat31111

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPat31111

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views20 pagesEP1461474B1

Uploaded by

nthung115Pat31111

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

EP 1 461 474B1

“ » el OMAN

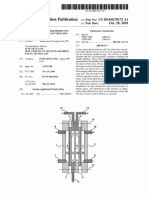

si (ty EP 1 461 474 B1

(12) EUROPEAN PATENT SPECIFICATION

(45) Date of pubication and mention (61) into

of the grant ofthe patent ABrL 27eem= ABIL 2agtee0

30.11.2011 Bulletin 2011/48 (Coz 1ag1 eee)

(21) Application number: 02790029.9 (86) Intemational application number:

PcT/us2002038861

(22) Date of fling: 05.12.2002

(87) Intemational publication number:

Wo 2002/048421 (12.06.2003 Gazette 2002/24)

(64) METHOD AND APPARATUS FOR PRODUCING NEGATIVE AND POSITIVE OXIDATIVE

REDUCTIVE POTENTIAL (ORP) WATER

VERFAHREN UND VORRICHTUNG ZUR ERZEUGUNG VON WASSER MIT NEGATIVEM UND

POSITIVEM REDOXPOTENTIAL (ORP)

PROCEDE ET DISPOSITIF DE PRODUCTION D’EAU AUX POTENTIELS D'OXYDO-REDUCTION

NEGATIFS ET POSITIFS

(84) Designated Contracting States (72) Inventor: SUMITA, Osa0

ATBEBGCHCYCZDEDKEEESFIFRGBGR | — Arakawa-ku, Tokyo-to (JP)

IEIT LILU MC NL PT SE SISK TR

Designated Extension States: (74) Representative: Hoeger, Stellrecht & Partner

ALLTLV MK RO Patentanwaite

Ublandstrasse 146

(80) Priority: 08.12.2001 US 336976 P 70182 Stuttgart (DE)

(43) Date of publication of poication: (56) References cted

28,09.2004 Bulletin 2004/40 EP-A-0949205 —_EP-A-1 289481

US-A-5616221 _US-A-5 625059

(73) Proprietor: OCULUS INNOVATIVE SCIENCES, US-A-5720869 _US-A- 5928 488

Inc. US-A1-2005 121 384 US-B1-6 296 744

Petaluma, California 94954 (US)

Note: Within nine months ofthe publication of the mention ofthe grant of the European patent In the European Patent

Bulletin, any person may give notice to the European Patent Office of opposition to that patent, in accordance with the

Implementing Regulations. Notice of opposition shall not be deemed to have been fled untl the opposition fee has been

paid. (Art. 99(1) European Patent Convention),

EP 1461 474.81

Description

Technical Field

[0001] The present invention relates generally to acidic and alkaline/oxidative and reductive potential water (ORP

water) and to methods of electralyzing saline solutions. More particularly, the present invention relates to amethod and

‘apparatus for producing negative and postive ORP water, and the water so produced, for use in sterlzation, decon-

tamination, disinfection, skin cleansing, and wound healing catalysis,

Background Art

[0002] The production of super-oxidized wateris an electrochemical, or oxidation-reduction process. This is commonly

referred to as an electrolytic or redox reaction in which electrical energy Is used to produce chemical change in an

‘aqueous solution. Electrical energy is introduced into and transported through water by the conduction of electrical

charge from one point to another in the form of an electrical current. In order forthe electrical current arise and subsist

there must be charge carriers in the water, and there must be a force that makes the carriers move, The charge carriers

ccan be electrons, as in the case of metal and semiconductors, or they can be positive and negative ions in the case of

solutions.

[0003] tis difficult to force electrical energy, or current, through pure water since itis nota charge carrier and is not

ionic in and of itself, Absolutely pure water, while theoretically simple Is, as a practical matter, virually impossible to

‘obtain, Hence, water in the form we commonly encounter t can and does conduct electrical energy, of curtent, due to

the presence of dissolved ions. The greater the concentration of dissolved ions, the greater the abiliy to conduct current

‘and the ability to produce a chemical change in the solution,

[0004] Since waters never pure itcan contain numerous dissolved substances. It invariably contains trace amounts

‘of HyO* and OH trom the dissociation of water. Itcan also contain dissolved gases, such as CO, and No that can also

be reactants. Water also contains various anions and cations. Asis well known, the HO molecule is poler; thats, ites,

‘an unequal charge distribution, This is due to the molecular structure and the unequel attraction for electrons exerted

by the oxygen and hydrogen atoms comprising the molecule. Thispolarty significantly enhances water's ablltyo dissolve

numerous substances, including fonic compounds such as sodium chloride or salt

[0005] Molecules of water can either be oxidized to O, by the removal of electrons or reduced to Hp by the addition

of electrons, Therefore water must always be considered a possible reactant. Typical reactions occur at ether the

cathode of the anode.

[0006] Atthe cathode reduction must occur. Many different reactions are possible however the folowing two reactions

are the most likely:

2H,O +26 ~ H, (gas) + 20H

2H,O+ 2c ~ H, (gas) + 2H,0

[0007] There are several other possible reactions at the cathode, none of which are easy to predict. It's necessary

tw consider which reactant is most easily reduced and which is reduced most rapidly. The strongest oxidizing agent is

not necessarily the fastest, Complications may arise when electric current is very large and the concentration of the

reactants is very small.

[0008] In the presence of NaCl other reactions are to be considered, such as the evolution of chlorine and hydrogen

{gas and the production of OH-. The OH’ or hydroxylion can cause significant increases in pH. Inthe electrolysis of NaCl,

Solutions show that OH-accumulates around the cathode. Cations move towardthe cathode andanionstoward the anode.

[0009] tthe anode oxidtion must occur. The most common rection in the presence of aqueous NaCl gives rise to

chlorine gas.

2Cr-2e" + Cl, (gas)

[0010] The overall reaction during the electrolysis of aqueous NaCI solutions shows the concentration of chlorine

decreasing and the concentration of OH: Inereasing. This condition in turn leads to other reactions and subsequent

products. Chlorine gas is partly dissolved in the solution, and reacts to produce hypechlorous acid according to the

following equation

EP 1461 474.81

Cl, +H,0 ~ HCIO and HCL

[0011] The resulting hydrochloric acid, HCI, can cause a significant drop in pH. There is also the possibilty that the

formation of HCl gives rise to other reactions simultaneously, but to an unknown degree. The production of atornic

‘oxygen is possible; however due tothe instablity iis not present for long or in high concentration. This reactivity can

give rise to other products such as oxygen gas, hydrogen peroxide, and ozone.

[0012] Combining the foregoing reactions and the resulting products and varying the process inputs and conadtions,

such as the amount and type of current, type and concentration of dissolved ions, and water purity, will give rise to water

of varying characteristics.

[0013] _Allofthe above-described reactions, when allowed to accur under controlled and optimal conditions, can result

in the production of water that contains oxidized epecies resulting in something termed "super-oxidized water." Super

oxidized water may have varying cheracteritis, including ether high or low pH, varying chlorine and chlorine compound

content, and varying degrees of oxygen and oxygen-containing compounds.

[0014] The most easily quantifiable characteristic of super-oxicized water is its pH. Depending upon the configuration

of the electrolytic cell, high pH water can be produced in the cathode chamber and low pH water can be produced in

the anode chamber. These can be referred to as anode or cathode water. Low pH (acidic) anode water also has chlorine

presentin various forms; .e., chlorine gas, chloride ion, hydrochloric acid, o hypachlorous acid. Oxygen in various forms

ccan also be present. The alkaline cathode water may have hydrogen gas present along with sodium ion, The process

water streams from these two electrolytic cells or chambers can be separated and analyzed,

[0015] Work performed in Japan has shown that each of the two types of water produced have unique properties.

(One of these properties is referred to as oxidation-reduction potential (ORP), This potential can be quantified using the

standard technique of measuring the electrical potential in rilvolts relative toa standard reference siverlsiver chloride

electrode, ORPs of approximately 1000mV have beenmeasured. Optical absorption spectra and electron spin resonance

have showed the presence of hypechlorous acid

[0016] thas long been known in the generel art of sterlization thet heat, tration, radiation, and chemicals may be

‘employed to remove unwanted microorganisms. However, only recently have developments in the art of electrolysis,

provided an alterative method of microbial disinfection and sterilization. Relatively recently, apparatus have been

{devised to optimize the consitions that favor the production of certain end products, including both cathode and anode

water of varying ORP and residual chlorine content. Super-oxicized water has a imited shelf fe and decreasing activity

‘over time, Data shows that ORP water may be effective when used in sterlization, decontamination, csinfection, skin

Cleansing, and wound healing catalysis.

[0017] Relevant prorartincludes United States Patent 5,992,171 to Malchesky, issued August®, 1999, which discloses

asterlization apparatus utilzing catholyte andanolyte solutions produced by electrolysis of water. The apparatusincludes

tray with an article receiving area, such that an article to be microbially decontaminated is positioned in the receiving

area and a microbe blocking li is closed over the article, A water electrolysis apparatus receives water, splls the water

into two seperate streams that pass respectively through an anode chamber and a cathode chamber, and exposes the

streams to an electric field that results in the production of a catholyte solution for cleaning and an anolyte solution for

sterlization. The anolyte and catholyte are selectively circulated through the article receiving area by a pump to clean

and microbially decontaminate the external surfaces and internal passages of an article located therein. The anolyte or

deactivated anolyte provides a sterile rinse solution. A reagent dispensing well receives an ampule or the ike. The

‘ampule contains internal compartments which are selectively accessed or opened to diepense detergent concentrate

‘andlor sterilant concentrate reagents into the circulating anolyte and catholyte solutions, A water treatment apparatus

ispenses either a salt or a cleaning agent into the water received from the source to vary the electrolysis reaction or to

form a cleaning solution to clean and flush the electrolysis apparatus, respectively,

[0018] UnitedStates Patent6, 171,551 to Malchesty , etal, issued Januaty9, 2001 teaches amethodof andapparatus

for electrolyticaly synthesizing peracetic acid and other oxidants. The electrolysis unit has an ion selective barrier for

separating an anodie chamber from a cathodic chamber, An electrolyte within the unit includes @ precursor, such as

potassium acetate, or acetic acid. A postive potential is applied to an anode within the anodic chamber, resulting in the

‘generation of a variety of shorter and longer lived oxidizing species, such as peracetic acid, hydrogen peroxide, and

‘ozone. In one preferred embodiment, 2 solution containing the oxiaizing species is transported toa site where articles,

such as medical instruments, are to be decontaminated. The oxidizing species are generated as needed, avoising the

need to store hazardous decontaminants.

[0019] United States Patent 5,507,932 to Robinson, issued April 16, 1996, teaches an apparatus for electrolyzing

fluids. The device ostensibly produces electrolyzed fluid that are particularly suited for treating physiological materials

‘such as whole blood, plasma, or cel isolates in order to reduce the effect of harmful microorganisms, A container holds

the fuid and a power supply provides a source of electrical curcent to an anode and a cathode positioned within the

container, The anode comprises a base material selected from ttanium and niobium, An outerlayer of platinum is bonded

EP 1461 474.81

tothe base, The anode comprises acylindrcal shape. The cathode is also connected othe power supply and comprises

titanium and has @ substantially cylindrical shape. The cathode Is positioned concentrically in relation to the anode. The

spacing between the cathode and the anode is not greater than a preferred amount. Moreover, the voltage potential

between the cathode and the anode is not greater than a preferred amount.

[0020] Finally, and most closely related to the present invention, United States Patent 6,296,744 to Djeirarishvli et

al, teaches an apparatus for the electrochemical treatment of a iquid medium. The apparatus contains at least one

rmidstream electrolytic cell wth unipolar electrades of postive and negative polarty, which are connected to @ source of

Continuous electical current and positioned on opposite sides of a semi-permeable diaphragm o membrane which

1100mV(vs., Ag/AgC); and secondly, alkaline and reductive water, pH 11-12, ORP<:

‘800m. ISO single exposure ocular and skin iritation studies in rabbits show thet ORP water having a pH of 12.44 is

not an intant to the ocular or dermal tissue of a rabbi.

[0044] Referring now to FIG. 5, a graph 60 which illustrates the properties of ORP water produced by the inventive

‘apparatus, it wll be appreciated that both the oxidative and the reductive ORP water produced by the inventive eystem

have industrialy applicable properties. Positive ORP (anode) water 62 produced through the use of a supporting elec

trolyte and having a pH of between 1.0 and 6.0 and an ORP between 0.75 and 1.5 V; NHE may be employed for metal

‘and organic contaminant removal, surface oxidation, and sterilization. Anode water 64 produced through the electrolysis,

of deionized water and having @ pH of between 5 and 7 and an ORP of between 0.75 and 1.25 may be employed to

prevent metal contamination, organic contaminant removal, surface oxidation, and sterilization. Negative ORP (cathode)

ater 66 produced in the Inventive system with a supporting electrolyte and having a pH of between 4 and 14 and an

CORP of between 0.0 and-1.25 is useful for particle removal and the prevention of surface oxidation, Cathode water 68,

produced using deionized water and having a pH of between 6 and 8 and an ORP of between 0.25 and 0.75 may be

usefully employed to prevent particle contamination and surface oxidation,

[0045] FIG. 6 is a chart 70 showing the stabilty of ORP water as a function of the cel type in which itis produced,

‘Specification for ORP Weter Apparatus

[0046] A specification fora preferred embodiment ofthe inventive apparatus is as flows:

4. Electrolyzed Water Supply Line Spectications

0047,

flow rate max. § Limi,

temperature less than 40

pressure 02 Mpa

», Middle Compartment Solution Line Specicaions

{ose}

flow rate max. 5 Limin,

temperature less than 40

pressure 0.05 Mpa

EP 1461 47481

c. Measurements

{0049}

pH te

ORP 1999 -1990m¥

flow rato 1-5

Specification of Components

[0050] Electrolysis devices are divided into types depending upon the flow rate of electrolyzed water: Flow rates of 1,

2, and 4 liters per minute are commonly available. The three compartment cells contained in the embodiments of the

Inventive apparatus are divided into TYPE A and TYPE 8 cells. TYPE A cels are suitable for producing electrolyzed

water ata flow rate of one Limin. TYPE B cells are sultable for elecrolyzing ata flow rate of two Limin. The flow rates,

‘of two and four Limin. are made possible by a parallel combination of TYPE A and TYPE B cells.

[0051] In order to produce electrolyzed water at constant pH and ORP, the electrolysis current must be kept constant.

In general, only voltage is controllable when using switching regulators. However, an MCS-1 may be provided. Ths is

‘a special current-contralled switching regulator. Moreover, the electrolysis current can be regulated by a microcomputer

contro

[0052] The speotications of these devices are summarized in Table

TABLE 1 SUMMARY OF SPECIFICATIONS

No | TypectGell | No. ofGel | Fiow Rate | Gurent | Vottage | Electic | TypeofPCB | Curent

Source Control

1 | Typea 1 1 10 16 | H1504 | Small None

2 | Type 1 1 10 17 [most | Smal Possible

3 | Tee 1 1 10 i [Mest | Large Possible

4 | Tea 2 2 10 16 | HA150A"2 | Small None

3 | Tweak 2 2 10 7 | wos-1"2 | Smal Possible

6 | Tea 2 2 10 17 | MCS1°2 | Large Possible

7 | Tee 2 2 13 24 | RWSSO0A_| Large Possible

8 | Te 1 2a 18 | RWSS00A_| Larue Possible

2 | Tes 2 4[_2 28 | sre6o | Lane Possible

10 | Type a{ a 15 | RWS300A" | Large Possible

2

[0083] FIGS. 1, 2 and, are schematic diagrams ofthe system configuration of the inventive apparatus. The arrange-

‘ment of structural and operative components can be described as follows:

(1) Case

[0054]

dimension 270x360x300 mm

material SUS804

(2) Gell

a. TYPEA

[0055]

number

structure

electrode

‘material platinum

EP 1461 474.81

to0r2

3 compartment type

60x 80 mm

platedititanium + platinummesh

frame

material pve

temperature Max, 45°C

pressure 02 Mpa

Conditions of electrolysis

inlet water

anode

cathode

middle

flow rate

electrolysis current

number

structure

electrode

material

frame

material

temperature

pressure

Conditions of electrolysis

inlet water

anode

cathode

middle

flow rate

electrolysis current

(@) Middle Compartment Tank

[0057]

(4) Circulation Pump

{ose}

pure water, tap water

pure water, tap water

lectrolytesolution, saturatedNaCleolution

usually 1 Limin.

Mex. 10.8

102

3 compartment type

60x 160 mm

platinum pleted ttanium + platinum mesh

pve

Mex. 45 °C

0.2 Mpa

pure water, tap water

pure water, tap water

electrolyte solution saturated NaClsolution\

usually 2 Limin.

Max. 20

umber 1

volume 2L.

material PE

(6) Switching Regulator

EP 1461 474.81

number 1

Input © AC 100 VW

output 1.6m3.6LImin,

[0059] Four models of switching regulator may be employed,

a. HK-150

[0060]

b.MCs+

[0061]

input AC to0Vs20w

output DC 1SVI0A

input AC 100

output DC 17V 11 A current control

cc. RWS200A

Input AC 100 V 400 W

output DC 1521 A (controllable by microcomputer)

4, $R660C

Input AC 100 V 1600W

output 06.28 V24 A (controllable by microcomputer)

(6) Contro! Panel (Print Circuit Board)

[0062] Two models of control panels are available: Small PCB and Large PCB.

‘a. Function of Small PCB {the control panel s shown in FIG. 4),

[0063]

operation

display

safety

electrolysis current

start to electrolyzestop to electrolyze

electrolysis current, electrolysis voltage, pH, ORP, flow rate

high and low

level of middle compartmenttank low temperature inthe case high flow rate low

», Function of Large PCB (control panel shown in FIG. 5)

[0064]

operation

dleplay

anode

cathode

safety

stat electrolysisstop electrolysis; automatically wash (stelize); selection of

reduction/oxidation water; top to pass water through device; start to pass water

through device; adjust the washing time

pH ORP flow rate

pH ORP flow rate

EP 1461 474.81

(continued)

electrolysis current high and tow

level of middle comp. tank low

level otwashingtank low

‘concentration of hydrogen high

flow rate low

temperature high

Claims

7

‘An apparatus for producing negative and postive oxidative reductive potential (ORP) water, comprising

‘a three-chambered electrolysis unit (14) having an anode chamber (16) and a cathode chamber (18), at least

‘one water supply in fluid communication with said anode and cathode chambers (16, 18) of said electrolysis

unit (14);

fan anode Inlet line (15a) connecting sald water supply with said anode chamber (16);

‘a cathode inlet ine (17a) connecting sald water supply with said cathode chamber (18);

source of electical potential (23) connectedtoa metal anode electrode (24) andametal cathode electrode (26);

fan anode outlet line (15b) for conveying positve ORP water away from said anode chamber (16);

‘a cathode outlet line (176) for conveying negetive ORP water away from sald cathode chamber (18); and

at least one collection receptacle for collecting ORP water conveyed from said electrolysis unt (14),

characterized in that said apparatus further comprises:

a saline solution chamber (20) interposed between said anode and cathode chambers (16, 18), wherein

‘said anode chamber (16) is separated from said saline solution chamber (20) by said metal anode electrode

(24) and a first ion exchange membrane (25), and wherein said catnode chamber (18) is separated from

‘said saline solution chamber (20) by sald metal cathode electrode (26) and a second ion exchange mem:

brane (27), and wherein sald saline solution chamber (20) includes a particulate insulting material which

permits the flow of solution through the saline solution chamber (20), but prevents a direct voltage potential

‘rom traveling between the two membranes (26, 27) or the migration of lonie species between the anode

and cathode chambers (16, 18);

at least one fluid supply of saline solution for circulation through sald saline solution chamber (20);

an intermectate inlet ine (21) connecting said saline solution chamber (20) with said fluid supply of saline

solution; and

anintermediate outlet line (21) forconveying fluid from said saline solution chamber (20)to said fluid supply.

‘The apparatus ofclaim 1, wherein said collection receptacles atank (28)for collecting negative ORP water conveyed

from said cathode chamber.

The apparatus of claim 1, further including a source of inert gas (38) in fluid communication with said collection

receptacle for providing a blanket of inert gas over ORP water produced by said apparatus.

‘The apparatus of ciaim 1, wherein sald collection receptacle includes an ultrasonic agitation system and an inductive

heater

‘The apparatus of claim 1, wherein said collection receptacie is atank (42) for collecting positive ORP water conveyed

from said anode chamber (16)

‘The apparatus of claim 1, wherein said apparatus includes two collection receptacles, including a tank (28) for

collecting negative ORP water conveyed from said cathode chamber (18) and a tank (42) for collecting positive

CORP water conveyed from said anode chamber (16)

The apparatus of claim 1, wherein said electrodes (24, 26) are generally flat and include a plurality of openings

10

10.

1"

EP 1461 474.81

‘exposing said lon exchange membranes (25, 27) to fluid in thelr respective anode or cathode chambers (16, 18)

‘The apparatus of claim 1, further including at least one flowmeter regulating flow rate of water to each of said anode

and cathode chambers (16, 18) when said apparatus isin use,

‘The apparatus of claim 1, further including @ high pH bulfer tank (34) and butfer line (37) in fluid communication

With said collection receptacle and with seid electrolysis unit (14)

The apparatus of claim 9, wherein said buffer line (37) includes atleast one particulate fiter (36) disposed between

sald buffer tank (34) and said electrolysis unit (14)

‘A method of producing negative and posite oxidative reductive potential (ORP) water, comprising the steps of:

(2) providing a three-chambered electrolysis unt according to claim 1 (14) having an anode chamber (16), 2

cathode chamber 18), and.asaline solution chamber (20) interposedbetween said anode andcathodechambers

(16, 18), wherein the anode chamber (16) is separated from the saline solution chamiver (20) by a metal anode

electrode (24) and a frst ion exchange membrane (25), wherein the cathode chamber (18) is separated from

the saline solution chamber (20) by a metal cathode electrode (26) and a secondion exchange membrane (27),

‘and wherein the saline solution chamber (20) includes @ particulate insulating material;

(©) providing a flow of water to and through the anode and cathode chambers (16, 18) from at least one water

supply in fluid communication with the anode and cathode chambers (16, 18):

(€) providing a circulating fluid flow of saline solution to and through the saline solution chamber (20) from at

least one fluid supply, wherein the saline solution chamber (20) Includes a particulate insulating material which

permits the flow of solution through the saline solution chamber (20) in an amount of at least 10 Limi, but

prevents a direct voltage potential from traveling between the two membranes (26, 27) or the migration of ionic

species between the anode and cathode chambers (16, 18)

(@ simultaneously with steps (b) and (c), providing electrical current to the anode and cathode electrodes (24,

26) from 2 source of electrical potential (23) connected to the anode electrode (24) and the cathode electrode

(26); and

(€} collecting ORP water produced by the electrolytic reaction in the electrolysis uit.

Patentanspriiche

\Vorrichtung zur Erzeugung von Wasser mit negativem und positivem Oxidations-Reduktions-Potential (ORP), um-

fassend:

cine Dreikammer-Elektrolyseeinhelt (14) mit einer Anodenkammer (16) und elner Kathodenkammer (18), wobel

mmindestens eine Wasserversorgung in Fluidverbindung mit der Anoden- und der Kathodenkammer (16, 18) der

Elektrolyseeinhett (14) steht

eine Anodeneinlassleitung (15a), welche die Wasserversorgung mit der Anodenkammer (16) verbindet;

eine Kathodeneinlassleitung (172), welche die Wasserversorgung mit der Kathodenkammer (18) verbindet;

eine Quelle elekrischen Potentials (23), welche mit einer Metall-Anodenelektrode (24) und einer Metall-Katho-

ddenelektrode (26) verbunden ist

eine Anodenauslassieitung (15b) zum Wegtransporteren von Wasser mit posiivem ORP aus der Anodenkam:

mer (16);

eine Kathodenauslassieltung (17b) 2um Wegtranspotieren von Wasser mit negativem ORP aus der Kathoden:

kammer (18); und

rmindestens ein Sammelgefa zum Sammeln von aus der Elektrolyseeinneit (14) ebtransportiertem ORP-Was-

dadurch gekennzeichnet, dass die Vorrichtung ferner umfasst

eine zwischen aie Anoden- und dle Kathodenkammer (16, 18) geschaltete Kochsalzidsungskammer (20),

‘wobei die Anodenkammer (16) durch ce Metall-Anodenelektrode (24) und eine erste lonenaustauschmem:

bran (25) von der

KochsalzJdsungskammer (20) getrennt ist und wobel dle Kathodenkammer (18) durch dle Metall-Katho:

denelektrode (26) und eine zweite Ionenaustauschimembran (27) von der Kochsalzibsungskammer (20)

getrennt ist und wobel die KochselzlBsungskammer (20) ein partkelférmiges Isoliermaterial umfasst, wel:

1"

10.

1

EP 1461 474.81

‘ches den Lésungsiluss durch die Kochsalzlésungskammer (20) erlaubt, aber verhindert, dass ein Gleich:

‘spannungspotential zwischen den zwei Membranen (25, 27) wandert oder ionische Spezies zwischen der

‘Anoden- und der Kethodenkammmer (18, 18) migreren;

mindestens eine Fluidversorgung an Kechsalzldsung zur Zrkulation durch die Kochsalzlésungskammer

(20) hinduret

eine Zwischeneinlassleitung (21a), welche die

Kochsalzl6sungskammer (20) mit der Fluidversorgung an Kechsalzlésung verbindet; und

eine Zwischenauslassletung (21b) zum Transpertieen von Fluid von der Kochsalzlisungskammer (20) 20

der Fluldversorgung,

\Vorrichtung nach Anspruch 1, wobel das SammelgefaB ein Tank (28) zum Sammeln von aus der Kathodenkammer

‘abtransportlerem Wasser mit negative ORP let.

Vorrichtung nach Anspruch 1, ferner umfassend eine Quelle fir Inertgas (38) in Fluidverbindung mit dem Sammet-

‘gef& 2um Beretstellen eines Inertgaspolsters Uber von der Vorrichtung erzeugtem ORP-Wasser.

\Vorrichtung nach Anspruch 1, wobeiidas Sammelgeféi ein Utraschall-Agitationssystem und einen Induktionshelzer

umfasst.

Vorrichtung nach Anspruch 1, wobel das Sammelgef& ein Tank (42) zum Sammeln von aus der Anodenkammer

(16) abtransportertem Wasser mit positivem ORP ist

\Vorrichtung nach Anspruch 1, wobei dle Vorrichtung zwei SammelgefBe umfasst, umfassend einen Tank (28) zum

‘Sammein von aus der Kathodenkammer (18) abtransportiertem Wasser mit negativem ORP und einen Tank (42)

zum Sammeln von aus der Anodenkammer (16) abtransportertem Wasser mit positivem ORP.

Vorrichtung nach Anspruch 1, wobel die Elektroden (24, 26) im Wesentlichen flach sind und eine Mehrzahl von

COtfnungen umfassen, welche die Ionenaustauschmembranen (26, 27) dem Fluid in ier jewelligen Anoden- oder

Kathodenkammer (16, 18) aussetzen.

Vorrichtung nach Anspruch 1, ferner umfassend mindestens einen Stromungsmesser, welcher ale Strémungsrate

von Wasser sowohl 2u der Anoden: als auch 2u der Kathodenkammer (16, 18) reguliet, wenn die Verrichtung in

Gebrauch ist,

Vorrichtung nach Anspruch 1, femer umfassend einen Hoch-pH-Puffertank (34) und eine Putfereitung (37) in Fluid

verbindung mit dem Sammelgefaf und mit der Elektrolyseeinhelt (14),

Vorrichtung nach Anspruch 9, wobei die Putterletung (87) mindestens ein Partkeliter (96) umfasst, welches 2wi

sschen dem Putfertank (34) und der Elektrolyseeinhelt (14) angeordnet it

Verfahren zur Erzeugung von Wasser mit negativem und positive Oxidations-Reduitions-Potential (ORP), um-

fassend dle Schrite:

(@) Bereltstellen einer Dreikammer-Elektrolyseeinhelt (14) nach Anspruch 1 mit einer Anodenkammer (16),

einer Kathodenkammer (18) und einer zwischen die Anoden- und die Kathodenkarmer (16, 18) geschalteten

Kochsalzlésungskammer (20), wobel die Anodenkammer (16) durch eine Metall-Anodenelektrode (24) undeine

erste lonenaustauschmembran (25) von der

Kochsalzi8sungskammer (20) gettennt it, wobel dle Kathodenkammer (18) durch eine Metall-Kathodenelek:

trode (26) und eine zweite lonenaustauschmembran (27) von der Kochselzlésungskammer (20) getrennt ist

Lund wobei die Kochsalzlésungskammer (20) ein patikelférmiges tsoliermaterial umfasst,

(©) Berettstellen eines Wasserfiusses 2u der Anaden- und der Kathodenkammer (16, 18) und durch dieselben

hindurch, ausgehend von mindestens einer Wasserversorgung in Fluidverbindung mit der Anoden- und der

Kathodenkammer (16, 18);

(6) Beretstollen eines Zirkullerenden Fluiflusses an Koohsalzlésung 2u der Kochsalzlacungskammer (20) und

‘durch dieselbe hindurch, ausgehend von mindestens einer Fluldversorgung, wobei die Kechsalziosungskammer

(20) ein partkeltérmiges Isoiermaterial umfasst, welches den Losungsfluss durch die Kechsalzidsungskammer

(20) in einer Menge von mindestens 10 1/min erlaubt, aber verhindert, dass ein Gleichspannungspotential

zwischen den zwel Membranen (25, 27) wandert oder ionische Spezies zwischen der Anoden- und der Katho-

2

EP 1461 474.81

denkammer (16, 18) migrieren;

(@) gleichzeitig mit den Schriten (b) und (c): Beretstellen eines elektrischen Stroms zu der Anoden- und der

Kathodenelektrode (24, 26) von einer Quelle elekrischen Potentials (28), welche mit der Anodenelektrade (24)

Und der Kathodenelektrode (26) verounden ist; und

(@) Sammeln von durch die elektrolytische Reaktion in der Elektrolyseeinheit erzeugtem ORP-Wasser.

Revendications

Appareil de production d'eau a potentiels doxydoréduction (POR) négatf et positf, comprenent

Lune unité¢'électrolyse @ trois chambres (14) comportant une chambre d anode (16) et une chambre de cathode

(18), au moins une alimentation en eau en communication fluidique avec lesdites chambres d'anade et de

cathode (16, 18) de lacte unité délectrolyse (14)

Une ligne d'admission d'anode (1a) raccordant laste alimentation en eau avec ladite chambre d'anode (16)

Une ligne d'admission de cathode (17a) raccordantladite alimentation en eau avec ladite chambre de cathode

(18);

Une Source de potentiel électrique (23) raccordée & une électrode anode en métal (24) et une électrode cathode

fen métal (26)

ne ligne de refoulement d'anode (155) permettant d'acheminer de l'eau & POR posit & cistance de ladite

chambre d'anode (16) ;

tne ligne de refoulement de cathode (176) permettant dlacheminer de eau & POR négatif distance de ladite

chambre de cathode (18) ; et

‘au moins un réceptacle de collecte permettant de collecter feau & POR acheminge de lade unlté d électrolyse

14),

caractérisé en ce que lesit apparell comprend en outre

Lune chambre de solution saline (20) interposée entre lescites chambres anode at de cathode (16, 18),

ol ladite chambre d'anode (16) est séparée de ladite chambre de solution saline (20) par laste électrade

anode en métal (24) et une premiére membrane échangeuse dons (26), et ol lite chambre de cathode

(18) est séparée de lacite chambre de solution saline (20) par lade élactrode cathode en métal (26) et

tune seconde membrane échangeuse dons (27), et

ol ladite chambre de solution saline (20) inclut une matiéve isolante partculaire qui permet écoulement

dune solution & travers la chambre de solution saline (20), mais empéche un potentiel de tension continue

de circuler entre les deux membranes (25, 27) ou la migration d'especes loniques entre les chambres

anode et de cathode (16, 18) ;

au moins une alimentation en fluide de solution saline pour circulation travers ladite chambre de solution

saline (20)

tune ligne admission intermédiaire (21a) raccordant ladte chambre de solution saline (20) avec ladite

alimentation en fuide de solution saline ; et

tune ligne de refoulementintermédiare (21b) permettant 'acheminer le fluide de lacite chambre de solution

ssaline (20) &laditealimentation en fuide.

‘Apparell selon la revendication 1, dans lequelledt réceptacie de collacte est une cuve (28) permettant de collecter

de Teau & POR négatf acheminge depuis ladite chambre de cathode,

‘Apparell selon la revendication 1, comprenant en outre une source de gaz inerte (38) en communication fluidique

avec leit réceptacle de collecte pour fournir une couverture de gaz inerte pardessus eau a POR produke par ledt

apparel

‘Appareil selon la revendication 1, dans leque! lealtréceptacle de collecteinclut un systéme d'agitation aux ultrasons

cetun chauttage par induction,

‘Agpareil selon la revendication 1, dans lequel ledit réceptacie de collecte est une cuve (42) permettant de collecter

do Teau & POR post acheminée depuls ladte chambre d'anode (16),

‘Apparell selon la revendication 1, dans lequel edit apparellinclut deux réceptacies de collecte, incluant une cuve

(28) permettant de collecter de l'eau & POR négati acheminée depuis ladte chambre de cathode (18) et une cuve

2

EP 1461 474.81

(42) permettant de collecter de eau & POR post acheminée depuis ladte chambre d'anode (16).

7. Appareil selon la revendication 1, dans lequel lesdltes électrodes (24, 26) sont généralement plates etincluent une

pluralté douvertures exposant lesdites membranes échangeuses dons (25, 27) & un fluide dans leurs chambres

anode ou de cathode (16, 18) respectves.

‘Appareil selon la revendication 1, incluant en outre au moins un débitmétre régulantle débit d'eau fourni a chacune

descites chambres danode et de cathode (16, 18) lorsque leclt apparel est en cours dutilsation.

9. Appareil selon la revendication 1, incluant en outre une cuve de tampon de pH haut (24) et une ligne de tampon

(87) en communication tuidique avec ledit réceptacle de collect et avec ladite unté d'électrolyse (14).

110. Appareil selon la revencicetion 9, dans lequel late ligne de tamoon (37) inclut au moins un fire & peticules (36)

dispose entre adite cuve de tampon (94) et lacite unit d'électrolyse (14).

111, Méthode de production d'eau’ potentiels d’oxydoréduction (POR) négatif et positf comprenantles étapes consistant

(a) foumir une unité d'électrolyse & trois chambres (14) selon la revendication 1, comportant une chambre

anode (16), une chambre de cathode (18), et une chambre de solution saline (20) interposde entre lesdites

chambres d'anade et de cathode (16, 18) ol la chambre d'anode (16) est séparée de la chambre de solution

saline (20) par une électrode anode en métal (24) et une premiére membrane échangeuse dons (26), ol la

chambre de cathode (18) est séparée de la chambre de solution saline (20) par une électrode cathode en métal

(26) et une seconde membrane échangeuse dons (27), et olla chambre de solution saline (20) inlut une

matiere isolante particule

(©) fournir une circulation d eau en direction de et travers les chambres danode et de cathode (16, 18) & partir

dau moins une alimentation en eau en communication fluidique avec les chambres anode et de cathode (16,

18);

(6) fournir un fux de fuide en circulation de solution saline en direction de et & travers la chambre de solution

saline 20) &partird'aumoins une alimentation en fluide, olla chambre de solution saline (20) inclutune matiére

isolante particulaire qui permet la circulation d'une solution & travers la chambre de solution saline (20) dans

Une quantité g'au moins 10 Limin, mais empache un potentiel de tension continue de circuler entre les deux

membranes (25, 27) ou la migration d'espaces loniques entre les chambres d'anode et de cathode (16, 18);

(@) simultanément avec les étapes (b) et (c),fournir un courant électrique aux électrodes anode et cathode (24,

26) a partir une source de potentiel électrique (28) connectée a I'électrode anode (24) et électrode cathode

26) et

(e) collecter 'eau & POR produte par la réaction électroiytique dans Funité délectrotyse.

“

EP 1461 474.81

D se}WMoL4 —> dung

b-9ld mea] oman

Vv J8}8WM0|3 —>

tH

ayaa

men ieee

tener ow =< or €7337

Addn QDd Fo] 973A77

Sv9 2N [svo zn 213031

% a ez 113037

8

EP 1461 474.81

z-

‘Old

dnd

dnd 1

Notlvinduio I SNRvaTo

-@) wns i i 30d

! NYE

ze ze

ULM dL ast

2k

SISAI0wLO373 an

waTIOYINOD | aSLVM SAILONGae

+s 2

YOLWINSSY SNIHOLIMS

Ua SALLVGIXO

6

lon Exchange Membrane

EP 1461 474.81

Solid Electrolyte

etl

lon Exchange Membrane

a aN 4 [ oabose,

OH

ee}

‘Anode 15b

te cts

OH HY 02

Hp eee

@©6oe Ht

@e6oe

| H,0

It 1] Kae? Nast Rg

H,0 \ 17a 27 Ho \2ta H,0

lon Exchange Membrane

Solid Electrolyte

H,0 + HCI + NH,OH

FIG._4

W

lon Exchange Membrane

‘Anode

EP 1461 474.81

09

S$" "Old

1 1 L n L 1

oz

18 onAIoN}Oey MA OY) WY PaUIeIGO Ma JO Seedold BUL

(AHN $°,) dO

18

EP 1461 474.81

SUIN 0%

0s0't - 006

9°'Sl4

8m0q dd 8 Lad Pes,

498M |G pue 8}4/01)99/3 ‘adh, {|e UO spuadep ow!

iL

eM +

OPE = 000'b.

O8t"t - oso'L

ee

p (uid) 3 10

Suonenueauo:

au a Ma

9

EP 1461 474.81

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only. It does not form part of the European

patent document. Even though great care has been taken in compiling the references, errors or omissions cannot be

excluded and the EPO disclaims all ability in this regard.

Patent documents cited in the description

+ US5982171 A, Malchesky [0017] + Us5616221 A [0022]

+ US6171551 8, Malchesky [0018] + US 5635053 A [0023]

+ US 8507982 A, Robinson [0019], + US5720869 A [0024]

+ US 6296744 8, Djeiranishvl (0020]

20

You might also like

- US2016250476A1Document35 pagesUS2016250476A1nthung115No ratings yet

- US4215694ADocument18 pagesUS4215694Anthung115No ratings yet

- US2017157404A1Document39 pagesUS2017157404A1nthung115No ratings yet

- US2012316619A1Document73 pagesUS2012316619A1nthung115No ratings yet

- US2021043292A1Document25 pagesUS2021043292A1nthung115No ratings yet

- Wo2023119063 Pamph 20230629 5671Document50 pagesWo2023119063 Pamph 20230629 5671nthung115No ratings yet

- 1698113897975046Document79 pages1698113897975046nthung115No ratings yet

- US2004106958A1Document29 pagesUS2004106958A1nthung115No ratings yet

- WO2021076062A2Document30 pagesWO2021076062A2nthung115No ratings yet

- WO2018051231A1Document13 pagesWO2018051231A1nthung115No ratings yet

- RU2602234C2Document25 pagesRU2602234C2nthung115No ratings yet

- US6251259B1Document23 pagesUS6251259B1nthung115No ratings yet

- WO2023119063A1Document50 pagesWO2023119063A1nthung115No ratings yet

- Patent 31888 Gen ADNDocument58 pagesPatent 31888 Gen ADNnthung115No ratings yet

- US5858201ADocument37 pagesUS5858201Anthung115No ratings yet

- US2002036134A1Document28 pagesUS2002036134A1nthung115No ratings yet

- US2005189237A1Document23 pagesUS2005189237A1nthung115No ratings yet

- Wo2012067018 Pdoc 20120524 9772Document16 pagesWo2012067018 Pdoc 20120524 9772nthung115No ratings yet

- US5593554ADocument11 pagesUS5593554Anthung115No ratings yet

- US5615764ADocument6 pagesUS5615764Anthung115No ratings yet

- Patent 31852 Thuoc Tru SauDocument112 pagesPatent 31852 Thuoc Tru Saunthung115No ratings yet

- KR20050022496ADocument7 pagesKR20050022496Anthung115No ratings yet

- Pulse Generator, Pulse Generation Method, Communication Apparatus and Communication MethodDocument4 pagesPulse Generator, Pulse Generation Method, Communication Apparatus and Communication Methodnthung115No ratings yet

- Us 2010270172 A 1Document7 pagesUs 2010270172 A 1nthung115No ratings yet

- Vietnamese Academies of Science & Technologies: Tiamkare Thitithamtada, Program Officer, ERCO and Ms. Tripti RajbhandariDocument22 pagesVietnamese Academies of Science & Technologies: Tiamkare Thitithamtada, Program Officer, ERCO and Ms. Tripti Rajbhandarinthung115No ratings yet

- CB275BDocument828 pagesCB275Bnthung115No ratings yet

- Curriculum VitaeDocument3 pagesCurriculum Vitaenthung115No ratings yet

- Us 2019218675 A 1Document14 pagesUs 2019218675 A 1nthung115No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)