Rutland 913 Windcharger Owners Manual - Marlec Engineering Co ...

Rutland 913 Windcharger Owners Manual - Marlec Engineering Co ...

Rutland 913 Windcharger Owners Manual - Marlec Engineering Co ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

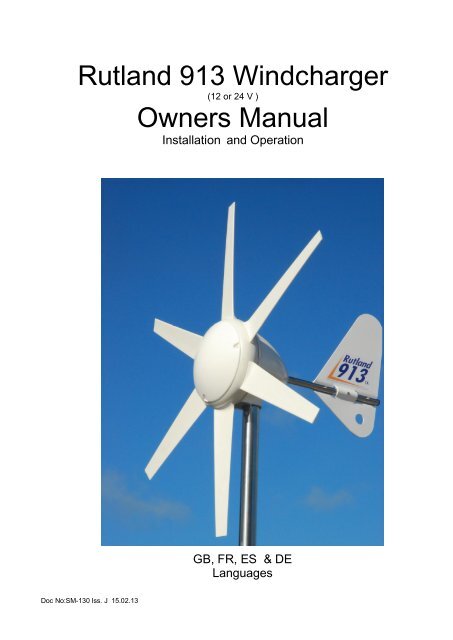

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

(12 or 24 V )<br />

<strong>Owners</strong> <strong>Manual</strong><br />

Installation and Operation<br />

GB, FR, ES & DE<br />

Languages<br />

Doc No:SM-130 Iss. J 15.02.13 1 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Doc No:SM-130 Iss. J 15.02.13 2 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

<strong>Co</strong>ntents<br />

Page:<br />

Introduction 4<br />

Summary of Features and Uses 4<br />

Profile and Dimensions 4<br />

General Guidelines and Warnings 5<br />

Check You Have Received 6<br />

Other Items 7<br />

Exploded View of the <strong>Rutland</strong> <strong>913</strong> 7<br />

Assembly & Installation<br />

Twelve Step Quick Start Guide 8<br />

Tower Preparation 9<br />

Blade Assembly 9<br />

Electrical <strong>Co</strong>nnection & Fitting to the Tower 10<br />

Up & Running<br />

Four Point Checklist 10<br />

Typical Wiring Diagrams for the <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong> 11<br />

Siting the <strong>Windcharger</strong><br />

General <strong>Co</strong>nsiderations 12<br />

Mounting The <strong>Windcharger</strong><br />

On Board Systems 13<br />

Land Based Systems 14<br />

Further System Requirements<br />

Batteries 15<br />

Cable Specifications 15<br />

Specification & Performance<br />

Guideline Performance Curve 16<br />

Maintenance & Troubleshooting<br />

Inspection & Maintenance 17<br />

Troubleshooting 18<br />

Installation Instructions (abbreviated) - French 20<br />

Installation Instructions (abbreviated) - Spanish 23<br />

Installation Instructions (abbreviated) - German 26<br />

For Your Records 29<br />

Doc No:SM-130 Iss. J 15.02.13 3 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Introduction<br />

<strong>Co</strong>ngratulations and thank you for purchasing your <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong>.<br />

The utmost of care goes into the manufacture of all our products in our ISO9001<br />

approved factory. To ensure you get the very best out of the <strong>Rutland</strong> <strong>913</strong> we<br />

recommend that you read this manual and familiarise yourself with its contents<br />

before installing and operating the <strong>Windcharger</strong> system.<br />

Summary of Features and Uses<br />

Aerodynamically styled to maintain good wind flow and stability.<br />

Low wind speed start up maximises power generation in low winds.<br />

High grade construction materials for durability, U.V. stability and weather<br />

resistance.<br />

Provides a D.C. power supply to charge 12 or 24 V battery banks.<br />

Designed for use on board sailing yachts, motor caravans, static caravans<br />

and sites where low power is needed for domestic devices as well as<br />

navigation equipment etc.<br />

Note: There are other <strong>Rutland</strong> <strong>Windcharger</strong>s designed for permanent<br />

installations on land - contact <strong>Marlec</strong> or visit www.marlec.co.uk to find out<br />

more.<br />

<strong>Rutland</strong> <strong>913</strong> Profile & Dimensions<br />

Fig 1<br />

Doc No:SM-130 Iss. J 15.02.13 4 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

General Guidelines & Warnings<br />

Mounting pole outside diameter MUST NOT exceed 48.5mm for at least the<br />

top 0.5m. Larger section poles must not be used as this will reduce the tower<br />

to blade clearance. In high wind conditions this could cause damage to the<br />

<strong>Windcharger</strong> by allowing the blade to come into contact with the mounting<br />

pole. A broken blade will cause turbine imbalance with consequent damage.<br />

When turning, the <strong>Windcharger</strong> is capable of generating voltages in excess of<br />

the nominal voltage. The turbine must never be allowed to rotate unless it is<br />

electrically connected to a regulator or batteries. <strong>Co</strong>nnecting an open circuit<br />

running turbine to the electrical system can cause serious damage to system<br />

components owing to excessive voltage. Caution must be exercised at all<br />

times to avoid electric shock.<br />

Stopping the turbine – this may be necessary to undertake battery<br />

maintenance. If possible stopping the turbine should be done in low wind<br />

speed conditions. The turbine can be slowed by rotating or orienting the tail<br />

fin upwind, this will slow the turbine sufficiently for it to be safely secured to the<br />

pole with rope. Avoid leaving the turbine tied up for any period of time, we<br />

recommend that the turbine either be covered to give protection from the<br />

weather or removed and stored in a dry location. We recommend the use of<br />

<strong>Marlec</strong> charge regulator that includes a shutdown switch.<br />

Choose a calm day to install the equipment and consider other safety aspects.<br />

No attempt to repair the system should be made until the wind generator is<br />

restrained from turning.<br />

The <strong>Windcharger</strong> is fitted with ceramic magnets, which can be damaged by<br />

heavy handling. The main generator assembly should be treated with care<br />

during transit and assembly.<br />

High winds – in high winds the windcharger’s built-in thermostat may operate<br />

to prevent the generator overheating. In this mode the output will cease and<br />

the turbine will temporarily speed up until such time as the lower level<br />

temperature is reached and the generator is once again connected and<br />

charging. This may be seen to cycle in prolonged high winds particularly in<br />

high ambient temperatures. If safely accessible you may prefer to temporarily<br />

secure the turbine.<br />

It is essential to observe the correct polarity when connecting the <strong>Windcharger</strong><br />

and all other components into an electrical circuit. Reverse connection will<br />

damage the <strong>Windcharger</strong> and incorrect installation will invalidate the warranty<br />

Doc No:SM-130 Iss. J 15.02.13 5 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

<br />

The fuse supplied must be fitted to protect the system.<br />

The <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong> is suitable for sailing boats and some land<br />

based applications. When storm winds are forecast the turbine can be<br />

restrained to minimise wear and tear particularly when installed on land<br />

based applications where Furlmatic model windchargers are normally<br />

recommended. Note that where the manufacturer recommends a furling type<br />

windcharger should have been used the warranty is invalidated in cases of<br />

storm damage.<br />

If in doubt, refer to your dealer, a competent electrical engineer or the<br />

manufacturer.<br />

Check You Have Received - See <strong>Rutland</strong> <strong>913</strong> Exploded View<br />

24 x No. 10x25mm special self-tapping screws<br />

1 x fuse and fuse holder<br />

1 x main generator assembly<br />

6 x aerofoil blades<br />

1 x nose cone + 3 x nylon fixing screws<br />

1 x 6mm Allen key<br />

1 x 2-way terminal block<br />

2 x M10 buttoncap screws<br />

2 x shakeproof washers<br />

In the event of loss or damage, consult your dealer or the manufacturer.<br />

Doc No:SM-130 Iss. J 15.02.13 6 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Other Items<br />

What You Will Need - Tools<br />

Suitable wire stripper<br />

Small terminal screwdriver<br />

Large flat blade screwdriver<br />

Crosshead screwdriver<br />

10mm Spanner or Socket<br />

Other Items You Will Need<br />

Mounting pole<br />

Cable<br />

Batteries<br />

Battery terminals<br />

<strong>Co</strong>nnector blocks (as<br />

determined by your total system)<br />

Other Items You May Have Selected<br />

HRSi, or HRDi Charge Regulator<br />

Cable (usually 2.5mm² twin core - Part No: 902-015)<br />

<strong>Rutland</strong> <strong>913</strong> Marine Mounting Kit and Stays Kit ( CA-12/02 & CA-12/32 )<br />

<strong>Rutland</strong> <strong>913</strong> Land Tower & Rigging Kit (Part Nos: CA-12/08 & CA-12/07)<br />

Short section of stainless steel tube to adapt into your own mounting design.<br />

Voltmeter & Ammeter<br />

Exploded View of The <strong>Rutland</strong> <strong>913</strong><br />

Nacelle Dome<br />

Six Blades with<br />

Twenty Four<br />

Screws<br />

Nose <strong>Co</strong>ne<br />

With Three<br />

Screws<br />

Post Adaptor<br />

Generator Hub<br />

Doc No:SM-130 Iss. J 15.02.13 7 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Assembly and Installation<br />

Twelve Step Quick Start Guide<br />

1. Choose an open site to expose the <strong>Windcharger</strong> to a clear flow of wind and avoiding<br />

obstructions. On board mount the <strong>Windcharger</strong> at least 2.4 metres above the deck and<br />

on land at least 4 - 6 m high. Read the full section on Siting.<br />

2. Choose a mounting pole with an internal diameter of 41.0mm and external<br />

diameter of no greater than 48.5 mm for the top 0.6m minimum to (i) prevent<br />

accidental damage and (ii) meet warranty conditions.<br />

3. Mount a charge regulator, from the <strong>Marlec</strong> range, to a suitable vertical surface<br />

and close to the battery. Follow instructions supplied with the charge regulator.<br />

4. Drill the mounting pole, if required, in preparation to accept and secure the<br />

<strong>Windcharger</strong>. See Assembly and Installation section.<br />

5. Choose suitable two core cable to connect from the <strong>Windcharger</strong> to the regulator. Up<br />

to 20m this should be of at least 2.5mm² cross sectional area. A short section of 4mm²<br />

cross sectional area is required to link the regulator to the battery. For other distances<br />

see the table in Cable Specifications.<br />

6. Position the mounting pole ( this may be done on the ground before raising the<br />

pole ) so that the selected cable can be threaded along it.<br />

7. Fit the blades, tail and nose to the <strong>Windcharger</strong> using fasteners provided. It is<br />

essential that 4 screws are fitted per blade.<br />

8. Join the cable threaded through the pole to the <strong>Windcharger</strong> output cable using<br />

the connector block provided. Wrap with insulating tape. Alternatively use a<br />

latching plug and socket. We recommend looping back the cable and securing<br />

with a cable tie to provide strain relief to the joint.<br />

9. Carefully push the cables down the pole whilst sliding the post adaptor down<br />

the pole. Line up the holes and secure in place with the screws and washers<br />

provided. Tighten with the Allen key. Do not allow the turbine to spin freely.<br />

10.Locate the charge regulator close to the battery and carefully follow ALL the<br />

regulator guidelines and installation sequences for connecting the <strong>Windcharger</strong><br />

through to the battery. Note : Install the in-line fuse supplied with the<br />

<strong>Windcharger</strong> between the battery and charge regulator.<br />

11.Ensure that the battery connections are permanent as the <strong>Windcharger</strong> should<br />

NEVER be operated without a connection to the battery.<br />

12.Raise and secure the <strong>Windcharger</strong>. It can now be allowed to rotate. Follow the<br />

“ Up and Running- Four Points Final Checklist” featured later. Also the<br />

“ General Guidelines and Warnings” section expands on the above points.<br />

Doc No:SM-130 Iss. J 15.02.13 8 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Assembly and Installation Detailed Instructions<br />

Fig.2<br />

Tower Preparation (Fig.2)<br />

1. Select a suitable pole from the suggested<br />

guidelines in Mounting the <strong>Windcharger</strong>.<br />

Note that the post adapter fitted to the <strong>913</strong><br />

is designed to fit inside a standard 41mm<br />

(1”) internal diameter tube.<br />

The adapter is provided with a flat on one<br />

side to clear the weld seam on seamed pipe.<br />

2. Mark and centre-punch two positions diametrically opposite, at 90° to the pipe<br />

seam if necessary, 20mm from top of the tube<br />

Note: Use metric measurements for this operation<br />

3. Drill two holes 10.5mm in diameter on centre-punch positions.<br />

Note :Use metric measurements for this operation<br />

Note: When using <strong>Rutland</strong> <strong>913</strong> Mounting Kit , items 2 and 3 can be ignored as<br />

<strong>Marlec</strong> supplied poles are pre-drilled.<br />

Fig. 3<br />

Blade Assembly (Fig.3)<br />

1. Place the generator assembly on a flat<br />

surface hub-side down. Position blade as<br />

shown. The blades will only fit one way<br />

around.<br />

2. Insert the protrusion at the trailing edge of<br />

the blade root fixing first into the socket to<br />

align with the corresponding recess in the<br />

blade socket. The blade can then be<br />

inserted with a lever action. A soft faced<br />

mallet may be used to tap the end of the<br />

blade to assist in fully locating the blade.<br />

3. First fit each blade with two special self-tapping screws provided to the rear of<br />

each blade by inserting each in turn through the cut out in the nacelle, rotating<br />

the generator each time until the holes align. Fit the remaining blade screws<br />

from the front of the generator hub. Check tightness of all screws but do not<br />

over-tighten. Caution- It is essential that all 4 screws are fitted!<br />

4. Fit the plastic nose dome in position on the front of the generator hub and<br />

secure in place with the three nylon screws provided.<br />

Alternatively the blades and nose dome can be fitted after mounting the generator<br />

assembly to the tower.<br />

Doc No:SM-130 Iss. J 15.02.13 9 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Electrical <strong>Co</strong>nnection and Fitting to The Tower<br />

1. Run the cable selected (see Table 1) down the inside of the pole.<br />

2. Select one of the 2 basic wiring systems on page 12 and follow the manual<br />

provided with the voltage controller.<br />

3. <strong>Co</strong>nnect the wind generator flying leads to the cable protruding from the<br />

tower using the connector block supplied, taking care to observe polarity.<br />

<strong>Co</strong>nnect the <strong>Windcharger</strong> + to cable + and windcharger – to cable –<br />

Red is + Positive<br />

Black is - Negative<br />

4. Wrap the connection with insulation tape to secure/protect from environment.<br />

Alternatively join the cables using a latching-type plug and socket.<br />

5. Locate the wind generator into the tower whilst gently easing the cable from<br />

the tower base to ensure the cable is not trapped. Secure the wind generator<br />

to the tower using the button cap screws and shake proof washers provided,<br />

tighten using the 6mm Allen key provided.<br />

Up and Running<br />

Four Point Final Checklist<br />

Before raising and securing the wind generator:<br />

1. Check the tightness of the blade & tail fixing screws and generator mounting<br />

screws.<br />

2. Check free rotation of the hub and yaw axis.<br />

3. Check that the cable is not trapped.<br />

4. Check that all electrical connections are secure and safe.<br />

The wind generator can now be raised into position.<br />

Take care to avoid all moving parts when raising and lowering the wind<br />

generator.<br />

When raised, secure the structure firmly in an upright position.<br />

Caution-The performance of your <strong>Windcharger</strong> will be impaired if the pole is<br />

not vertical.<br />

Doc No:SM-130 Iss. J 15.02.13 10 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Typical Wiring Diagrams For The <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Typical Wiring Scheme For A Single Battery Bank<br />

Solar Panel<br />

Maximum<br />

160 Watts<br />

HRSi Charge<br />

Regulator<br />

12/24 V<br />

Typical Wiring Scheme For Single or Dual Battery Banks<br />

Solar Panel<br />

Maximum<br />

160 Watts<br />

HRDi Charge<br />

Regulator<br />

12/24 V<br />

In-Line Fuse<br />

Second battery<br />

optional<br />

Doc No:SM-130 Iss. J 15.02.13 11 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Siting The <strong>Windcharger</strong><br />

General <strong>Co</strong>nsiderations<br />

The location and height of the mounting pole or tower for your wind turbine will<br />

be the major factor in the overall performance of your system. The smooth flow<br />

of wind over land and water is often interrupted by a multitude of<br />

obstructions causing wind sheer and turbulence.<br />

Wind shear describes the interference between the fast moving upper air and<br />

the slow moving air close to the ground and the resulting decrease in average<br />

wind speed as one gets closer to the ground.<br />

Turbulence is caused by the wind passing over obstructions such as moored<br />

boats, trees, and buildings.<br />

Both wind sheer and turbulence diminish with height and can be overcome<br />

simply by putting the turbine sufficiently high above them as shown in Fig 4.<br />

Windspeed decreases and turbulence increases where obstructions exist.<br />

<strong>Co</strong>nsider also that downwind obstructions can be as detrimental to performance<br />

as upwind obstructions.<br />

It is therefore essential that the wind generator should be located in an area as<br />

free as possible from disturbed wind flow.<br />

Fig. 4<br />

WIND DIRECTION<br />

AREA OF TURBULENCE<br />

H<br />

2H<br />

2H<br />

20H<br />

Doc No:SM-130 Iss. J 15.02.13 12 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Mounting The <strong>Windcharger</strong><br />

Fig. 5<br />

Fig. 6<br />

On Board Systems<br />

The wind generator should be mounted in a safe<br />

position, a minimum of 2.3 metres (7.6 feet) above<br />

the deck and away from other obstacles which<br />

could interfere with the blades or tail assembly<br />

(Fig. 5).<br />

The <strong>Rutland</strong> <strong>913</strong> Mounting & Stays Kits (Part No.<br />

CA-12/02 & CA-12/32) are available for deck<br />

mounting, or short sections of stainless steel tube<br />

of 1200mm (47”) and 600mm (23”) pre-drilled are<br />

also available for your own fabrication.<br />

The <strong>Rutland</strong> <strong>913</strong> is designed to fit inside an<br />

aluminium or stainless steel tube with an internal<br />

diameter of 41mm (1”). IMPORTANT: The<br />

external diameter MUST NOT exceed 48.5mm<br />

(1), see Warning in Introduction.<br />

Suitable tubes: Stainless Steel 1 3 / 4 ”16 SWG and<br />

Aluminium 1 7 / 8 ” 10 SWG<br />

Fig. 7<br />

We suggest the following mountings according to<br />

preference and site conditions:-<br />

Push pit (Fig.6)<br />

A suitable pole mounted to the deck with deck<br />

plates and solid guys is the most popular method of<br />

mounting the <strong>Windcharger</strong> on yachts, eg. <strong>Rutland</strong><br />

<strong>913</strong> Mounting & Stays Kit.<br />

Fig. 8<br />

Mizzen (Fig.7)<br />

Mizzen mounting is suitable on larger yachts,<br />

taking advantage of greater wind flow the higher<br />

the wind turbine is mounted.<br />

River Boats (Fig.8)<br />

A pivot pole is ideal for riverboats as the<br />

<strong>Windcharger</strong> can easily be raised and lowered.<br />

Doc No:SM-130 Iss. J 15.02.13 13 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Fig. 9<br />

Centre pivoted pole<br />

Fig. 10<br />

Base pivoted with gin pole<br />

Land Based Systems<br />

The <strong>Rutland</strong> <strong>913</strong> is suitable for some land based<br />

temporary and leisure applications. The Furlmatic<br />

<strong>Windcharger</strong> model is recommended for land<br />

based remote and exposed locations.<br />

The <strong>Rutland</strong> <strong>913</strong> is designed to fit inside<br />

aluminium, stainless or steel tube with an internal<br />

diameter of 41mm. (1”). IMPORTANT: The<br />

external diameter MUST NOT exceed 48.5mm<br />

(1), see Warning in Introduction.<br />

A suitable mounting pole can be erected using a<br />

6.5 metre (21 feet) galvanised (medium) tube.<br />

The tube must be supported by a minimum of four<br />

guy lines. The attachment points for the guy lines<br />

to the tower should be securely fixed to the tower.<br />

The guy wires should be a minimum of 4mm<br />

(0.16”) in diameter.<br />

The shackles should be a minimum of 5mm<br />

(0.20”) in diameter.<br />

Rigging screws should be a minimum of 5mm<br />

(0.20”) in diameter.<br />

All items should be galvanised or stainless<br />

steel for protection against corrosion.<br />

Where guy lines are looped, the loop must<br />

incorporate a thimble and be fitted with a<br />

minimum of three rope grips.<br />

All ground fixings must be made suitable<br />

according to the terrain.<br />

We suggest pivot type towers as these allow for<br />

easier installation and lowering for access to the<br />

wind generator. Two forms of pivot tower are<br />

suggested in Figs 9 & 10.<br />

A base-hinged 6.4m tall Land Tower Kit (Part<br />

No: CA-12/08) and Rigging Kit (Part No:<br />

CA-12/07) are available from <strong>Marlec</strong>.<br />

Doc No:SM-130 Iss. J 15.02.13 14 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Further System Requirements<br />

Total = 12v<br />

120Ah<br />

1440Wh<br />

60Ah<br />

12v<br />

60Ah<br />

12v<br />

In parallel to increase amp<br />

Total = 24v<br />

60Ah<br />

1440Wh<br />

60Ah<br />

12v<br />

60Ah<br />

12v<br />

In series to increase voltage<br />

Batteries<br />

Leisure/Deep Cycle batteries are specifically<br />

designed for good performance in terms of<br />

charge/discharge cycles. Batteries are the<br />

most important part of your battery charging<br />

system and should be sized according to your<br />

load requirements and provide at least 3 days<br />

reserve capacity. This will reduce cycling,<br />

prolong the life of the battery and ensure<br />

system reliability during periods of low wind.<br />

Permanent connections should always be made<br />

to the battery terminals. Never use crocodile<br />

clips or similar devices.<br />

We strongly recommend that one of the voltage<br />

regulators available from <strong>Marlec</strong> is fitted to<br />

prevent batteries becoming overcharged in<br />

strong winds and is essential with gel/sealed<br />

batteries.<br />

Batteries may be linked as shown in the figures<br />

10 and 11. It is essential to observe polarity as<br />

follows:<br />

Red is + Positive<br />

Black is - Negative<br />

Cable Specification<br />

Cable<br />

Run<br />

(m)<br />

12V<br />

Cable Size<br />

24V<br />

mm² AWG mm² AWG<br />

0-20 2.5 13 1.5 15<br />

21-30 4 11 2.5 13<br />

31-45 6 9 4 11<br />

46-80 10 7 6 9<br />

The cable used for connection of the<br />

<strong>Windcharger</strong> to the batteries should be in<br />

accordance with table 1. The use of a<br />

smaller cable than recommended will<br />

reduce the performance of the charging<br />

system.<br />

Cable and connectors are available from<br />

your dealer or the manufacturer.<br />

Doc No:SM-130 Iss. J 15.02.13 15 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Specification and Performance<br />

Guideline Performance Curve<br />

Note : The curve shown below is for clear, non-turbulent wind conditions; this<br />

may not be achieved in some installations. Refer to the section on Siting to<br />

optimise performance at your site. Wind speeds are those flowing across the<br />

turbine of the <strong>Windcharger</strong> and may not reflect those measured at mast top or<br />

those reported by the Met. Office.<br />

20<br />

10<br />

18<br />

9<br />

16<br />

WINDSPEED CONVERSION<br />

8<br />

Charge into 12 V Battery (Amperes)<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

MPH = Knots x 1.15<br />

M/S = Knots x .515<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Charge into 24 V Battery (Amperes)<br />

0 5 10 15 20 25 30 35 40<br />

Windspeed (Knots)<br />

Doc No:SM-130 Iss. J 15.02.13 16 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Maintenance and Troubleshooting<br />

Inspection and Maintenance<br />

The <strong>Rutland</strong> <strong>913</strong> requires no scheduled maintenance but an annual inspection<br />

should be carried out to monitor the general condition of the system to ensure<br />

the electrical and mechanical integrity and safety of the system.<br />

WARNING! Before inspection, the turbine should either be lowered to the<br />

ground or tied to prevent the generator from turning. To stop the generator from<br />

turning proceed as follows:<br />

1. Either rotate the switch to stall mode on the charge regulator if used OR turn<br />

the wind generator out of the wind (180°) using the tail, a hole is<br />

provided in the tail fin to assist in this. The generator will gradually slow down.<br />

2. Tie a blade to the mounting pole to prevent it from rotating.<br />

Whilst the generator is stationary, the following routine checks should be<br />

performed:<br />

1. Check the blades for damage, eg chips or nicks. Replace any damaged<br />

blades. The turbine should not be operated with damaged blades as this may<br />

cause imbalance resulting in premature wear and possible failure. Check the<br />

blade screws for tightness.<br />

2. Check all other nuts, bolts and screws for tightness.<br />

3. Check the yaw axis for free rotation.<br />

4. Check tower assembly for condition.<br />

5. Check the tension of the guy wires if applicable. The tension of guy wires<br />

should be checked frequently during the first year.<br />

6. The unit can be wiped with a mild detergent and rinsed with water to remove<br />

dirt and debris.<br />

Note: The <strong>Windcharger</strong> is designed for continuous running to achieve<br />

maximum resistance to water ingress. Should you wish to take the<br />

unit out of service for an extended period it is recommend that the<br />

unit be removed from the mounting and stored in a dry location or<br />

covered.<br />

Doc No:SM-130 Iss. J 15.02.13 17 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Troubleshooting<br />

In the unlikely event that your <strong>Rutland</strong> <strong>913</strong> should develop a defect, the turbine<br />

should first be tied to prevent the blades from turning to perform the static tests<br />

below. (Follow the procedure described in the Inspection and Maintenance<br />

section) It will be necessary to let it run for the tests to check for power<br />

production.<br />

Read the Electrical <strong>Co</strong>nnection and Up and Running sections and b satisfied<br />

that your system complies.<br />

Is there sufficient wind The <strong>Rutland</strong> <strong>913</strong> needs 5 knots wind speed to start<br />

charging. The wind speed across the turbine blades may be greatly reduced in a<br />

marina or built-up area compared with the reading on a masthead anemometer<br />

or weather reports.<br />

Static Tests:<br />

Is the battery in good condition Check the voltage and electrolyte level of<br />

each battery.<br />

Check electrical continuity throughout the system, especially corrosion and<br />

poor connections in cable joins and connector blocks.<br />

Running Tests:<br />

Check for power output from the windcharger, following this procedure:<br />

1. Set a digital multimeter to DC Amps, scale of between 5 and 10 if possible.<br />

<strong>Co</strong>nnect the meter positive (+) probe to the wind generator output positive<br />

cable and the meter negative (-) to the regulator input positive. Provided<br />

there is sufficient wind there should be a current reading. This establishes<br />

that power is being delivered.<br />

2. Using the same multimeter setting as above measure between the regulator to<br />

battery + and the battery +. Provided there is sufficient wind there should be a<br />

current reading. This establishes if power is passing through the regulator.<br />

3. If both above are unsuccessful set the multimeter to DC Volts. Disconnect the<br />

wind generator from the regulator and connect the meter + to the wind<br />

generator + and the meter – to the wind generator -. Provided there is<br />

sufficient wind there should be a variable voltage reading according to the<br />

speed of the wind seen at the wind turbine. This will establish if the wind<br />

generator is able to deliver power or not.<br />

4. If tests 1 and 3 are successful but test 2 fails to produce results connect the<br />

wind generator directly to the battery. Set the digital multimeter to DC Amps<br />

and measure power between the wind generator + and the battery +. If a<br />

reading is measured, providing there is sufficient wind, then the regulator is<br />

faulty.<br />

5. If the wind turbine fails to deliver any current or open circuit V reading<br />

undertake the further tests below.<br />

Doc No:SM-130 Iss. J 15.02.13 18 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

6. Mechanical inspection. It may be necessary to remove the windcharger from<br />

its pole for the following tests.<br />

Check the brushes and slipring for wear or damage. To inspect the brushes,<br />

remove the nacelle by removing the three fixing screws and slide the nacelle<br />

backwards towards the tail fin. The brushes and slipring can be inspected by<br />

removing the four self-tapping screws holding the brush holder assembly in<br />

place. Remove any black deposits from slipring with emery paper. Heavy<br />

deposits and reduced power indicate a possible reverse connection to the<br />

battery (see Page 10).<br />

Check hub for free rotation with generator disconnected from battery.<br />

If the hub does not rotate freely, check for a possible short circuit in the wiring.<br />

If no wiring fault is found refer to your dealer or manufacturer.<br />

If the above checks have identified a need for spare parts or failed to identify the<br />

problem you should contact your dealer. Visit www.marlec.co.uk for further fault<br />

finding guides and support.<br />

If in doubt, refer to your dealer or manufacturer.<br />

Doc No:SM-130 Iss. J 15.02.13 19 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Introduction<br />

Francais<br />

Félicitations pour votre achat d’une éolienne <strong>Rutland</strong> <strong>913</strong> ! <strong>Co</strong>mme tous nos produits, elle a été<br />

fabriquée avec le plus grand soin, dans notre usine certifiée ISO 9001. Pour obtenir pleine<br />

satisfaction de votre éolienne <strong>Rutland</strong> <strong>913</strong>, nous vous recommandons de lire entièrement ce<br />

manuel et de vous familiariser avec son contenu avant de commencer l’installation ou de l’utiliser.<br />

Principales caractéristiques et applications<br />

<strong>Co</strong>nception aérodynamique pour une bonne prise au vent.<br />

Tourne avec peu de vent pour optimiser les performances même par vent faible.<br />

Matériaux de qualité pour une durée de vie optimale, une bonne résistance aux UV et aux<br />

conditions climatiques.<br />

Permet de charger des batteries 12V ou 24V.<br />

<strong>Co</strong>nçue pour fonctionner sur des bateaux, des camping-cars, des mobil-homes ou sur des sites<br />

où une faible puissance est nécessaire pour faire fonctionner des appareils ménagers, de<br />

l’instrumentation, etc.NB : il existe d’autres modèles d’éoliennes conçues pour une installation<br />

terrestre permanente. Venez les découvrir sur notre site www.marlec.co.uk<br />

Informations générales et mises en garde<br />

Le diamètre externe du mât ne doit pas être supérieur à 48,5mm, au moins sur les 50 derniers<br />

centimètres. Ne pas utiliser de mât plus gros au risque de réduire le jeu nécessaire entre les<br />

pales et le mât. En cas de vents forts, les pales risquent de heurter le mât et de s’endommager.<br />

Une pale brisée provoque un déséquilibre capable d’entraîner des dégâts importants.<br />

Lorsqu’elle fonctionne, l'éolienne peu générer de l'électricité à haute tension, c’est pourquoi elle<br />

ne doit pas tourner tant qu’elle n’est pas reliée à un régulateur ou à des batteries. Raccorder<br />

directement l’éolienne à l’installation électrique peut provoquer des dégâts importants en raison<br />

de la surtension. Pour éviter tout risque d’électrochoc, vous devez être constamment vigilant.<br />

Stopper l’éolienne – Cela peut s’avérer nécessaire avant d’intervenir sur les batteries. Dans la<br />

mesure du possible, il est préférable de le faire lorsque le vent est faible. L’éolienne peut alors<br />

être ralentie en orientant l’aileron contre le vent ce qui permet de l’immobiliser en l’attachant au<br />

mât avec une corde. Éviter de l’immobiliser trop longtemps. Il est recommandé de la couvrir<br />

pour la protéger des effets du climat ou de la déposer pour l’entreposer en lieu sec. Les<br />

régulateurs HRSi et HRDi sont équipé d’un interrupteur Marche/Arrêt.<br />

Entres autres éléments de sécurité, effectuer l’installation par temps calme.<br />

Aucune tentative de réparation ne doit être engagée tant que l'éolienne n'est pas immobilisée.<br />

L'éolienne est équipée d'aimants céramiques qui peuvent facilement être abîmés lors de leur<br />

manipulation. Elle doit être maniée avec précaution durant le transport et le montage.<br />

Vents forts – Par vents forts, la sécurité thermique intégrée peut stopper l’éolienne pour<br />

l’empêcher de surchauffer. Dans ce cas, l’éolienne ne produit plus d’électricité et sa vitesse de<br />

rotation peut augmenter, le temps nécessaire au refroidissement. Elle se remet automatiquement<br />

en marche lorsque la température a baissé. Si les vents forts persistent et plus particulièrement<br />

par temps chaud, vous verrez ces cycles se répéter. S’il vous est possible d’accéder à<br />

l’éolienne en toute sécurité, il est préférable de la bloquer temporairement.<br />

Doc No:SM-130 Iss. J 15.02.13 20 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Il est essentiel de respecter les polarités lors du branchement de l'éolienne<br />

ainsi que de tous les autres composants du système électrique. Inverser les<br />

branchements endommagerait l'éolienne et une installation incorrecte<br />

annulerait la garantie.<br />

Le fusible fourni doit être installé pour protéger l'appareil.<br />

L’éolienne <strong>Rutland</strong> <strong>913</strong> est conçue pour une utilisation sur des bateaux à voiles<br />

ou certaines applications terrestres. Lorsque des vents d’orage sont annoncés,<br />

l’éolienne peut être immobilisée pour prévenir les risques d’usure et de casse,<br />

notamment lorsqu’elle est installée sur un site terrestre exposé aux vents forts<br />

pour lesquels il est recommandé d’utiliser des modèles Furlmatic (avec mise en<br />

drapeau automatique). Si ce type d’éolienne est recommandé par le<br />

constructeur pour une application, mais qu’il n’en est pas tenu compte, la<br />

garantie ne fonctionnera en cas de dommages occasionnés par des vents forts.<br />

En cas de doute, se référer à votre revendeur, à un ingénieur compétent en<br />

électricité ou au fabricant.<br />

6 x Pâles et<br />

24 x Vis 10 x 25mm<br />

autotaraudeuses<br />

1 x Nacelle<br />

1 x Adapteur de<br />

poteau<br />

1 x <strong>Co</strong>rps<br />

d’éolienne<br />

1 x Cône avant +<br />

3 vis de fixation<br />

Doc No:SM-130 Iss. J 15.02.13 21 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Guide d’installation en douze étape<br />

1. Choisir un emplacement dégagé pour que l’éolienne soit exposée au vent sans aucune<br />

obstruction. A bord d’un bateau, la monter au minimum 2,5 m au-dessus du pont et sur terre à<br />

une hauteur de 4 à 6 m minimum. Lire le chapitre « Choix de l’emplacement ».<br />

2. Prévoir un mât de 41 mm de diamètre intérieur et de 48,5 mm maximum de diamètre extérieur,<br />

au moins sur les 50 derniers centimètres, pour prévenir tout risque de dégâts et effectuer un<br />

montage conforme aux exigences de la garantie.<br />

3. Monter un régulateur, choisi dans la gamme proposée par <strong>Marlec</strong>, sur un plan vertical et à<br />

proximité des batteries. Suivre les instructions de montage fournies avec le régulateur.<br />

4. Le cas échéant, percer les trous de fixation sur le mât et fixer l’éolienne au mât. Voir le<br />

chapitre « Assemblage et installation de l’éolienne ».<br />

5. Choisir un câble adéquat à deux conducteurs pour relier l’éolienne au régulateur. Jusqu’à<br />

20 m de longueur, choisir un câble d’une section de 2,5 mm². Pour relier le régulateur à la<br />

batterie, un câble de 4 mm² est nécessaire. Pour d’autres longueurs, se reporter au chapitre<br />

« Type de câble ».<br />

6. Passer le câble dans le mât (cela peut se faire au sol, avant de dresser le mât).<br />

7. Fixer les pâles, l’aileron et le cône avant sur l’éolienne, à l’aide des fixations fournies. Chaque<br />

pâle doit être montée avec les quatre vis fournies.<br />

8. Utiliser le bloc de connexion fourni pour raccorder le câble passé dans le mât au câble sur<br />

l’éolienne. Protéger la connexion avec du ruban isolant. Vous pouvez aussi utiliser une prise<br />

Nous recommandons d’effectuer une boucle et de la fixer afin de diminuer la contrainte sur la<br />

connexion.<br />

9. Pousser les câbles à l’intérieur du mât avec précaution, et poser l’adaptateur dans le mât.<br />

Aligner les trous de fixation et sécuriser le montage avec les rondelles et les vis fournies.<br />

Serrer en utilisant la clé Allen également fournie. Empêcher la turbine de tourner à vide.<br />

10. Monter le régulateur à proximité de la batterie et suivre rigoureusement toutes les instructions<br />

ainsi que la séquence de branchements pour raccorder l’éolienne aux batteries. NB : monter<br />

en ligne le fusible fourni avec l’éolienne entre le régulateur et la batterie.<br />

11. L’éolienne ne doit en aucun cas pouvoir fonctionner sans être raccordée à la batterie,<br />

s’assurer que la connexion soit permanente.<br />

12. Dresser et fixer le mât. L’éolienne est maintenant prête à fonctionner. Effectuer les vérifications<br />

(en quatre points) indiquées au chapitre « Dressage et mise en service de l’éolienne ».<br />

Les « Informations générales et mises en garde » énoncées ci-dessus doivent également avoir<br />

été intégrées.<br />

Doc No:SM-130 Iss. J 15.02.13 22 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Introducción<br />

Espanol<br />

Felicitaciones y gracias por comprar un cargador eólico <strong>Rutland</strong> <strong>913</strong>.<br />

Utilizamos sumo cuidado en la fabricación de todos nuestros productos en nuestra fábrica<br />

aprobada por la Norma ISO9001. Para asegurarnos de que reciba lo mejor de nuestro <strong>Rutland</strong><br />

<strong>913</strong>, le recomendamos que lea este manual y se familiarice con su contenido antes de instalar y<br />

poner en funcionamiento el sistema del cargador eólico.<br />

Resumen de características y usos<br />

estilo aerodinámico para mantener estabilidad y un buen flujo del viento<br />

el arranque con vientos a baja velocidad maximiza la producción de energía en vientos de<br />

poca fuerza<br />

materiales de construcción de gran calidad para mayor durabilidad, estabilidad U.V y<br />

resistencia a la intemperie<br />

proporciona una fuente de alimentación CC para cargar bancos de batería de 12 o 24 voltios.<br />

diseñado para ser utilizado a bordo de yates a vela, casillas rodantes motorizadas, casillas<br />

rodantes estáticas y sitios en donde se necesita una baja potencia para dispositivos<br />

domésticos como así también equipos de navegación, etc.<br />

Nota: Existen otros cargadores eólicos <strong>Rutland</strong> diseñados para instalaciones permanentes en<br />

tierra, para obtener mayor información, comuníquese con <strong>Marlec</strong> o visite la página Web<br />

www.marlec.co.uk.<br />

Pautas y advertencias generales<br />

El diámetro externo del mástil de montaje NO DEBE exceder los 48,5 mm aunque sea en los<br />

0,5m superiores. No utilice mástiles más grandes ya que esto reducirá el espacio entre la<br />

torre y la paleta. En condiciones de vientos fuertes, esto puedo provocar daños al cargador<br />

eólico ya que la paleta entra en contacto con el mástil de montaje. Una paleta rota producirá<br />

un desequilibrio en la turbina y daños posteriores.<br />

Al girar, el cargador eólico es capaz de generar voltajes superiores al voltaje nominal. Nunca<br />

permita que la turbina gire a menos que se encuentre conectada eléctricamente a un<br />

regulador o a una batería. La conexión de una turbina que funciona con un circuito abierto al<br />

sistema eléctrico puede provocar daños graves a los componentes del sistema por el<br />

excesivo voltaje. En todo momento, tenga cuidado y evite las descargas eléctricas.<br />

Detención de la turbina: puede ser necesaria para realizar el mantenimiento de la batería. Si<br />

es posible, detenga la turbina en condiciones de viento a baja velocidad. Disminuya la<br />

velocidad de la turbina girando o dirigiendo la aleta de la cola contra el viento; esto diminuirá<br />

la velocidad de la turbina lo suficiente como para que ésta se pueda sujetar con una soga y<br />

sin peligro al mástil. Evite dejar la turbina atada durante mucho tiempo; le recomendamos que<br />

cubra la turbina para protegerla de la intemperie o retírela y guárdela en un lugar seco. Le<br />

recomendamos que utilice el regulador de carga <strong>Marlec</strong> que incluye un interruptor de<br />

desconexión.<br />

Elija un día sin viento para instalar el equipo y tenga en cuenta otros aspectos de seguridad.<br />

No intente reparar el sistema hasta que el generador de viento este sujeto y no pueda girar.<br />

El cargador eólico esta ajustado con imanes cerámicos que pueden dañarse durante una<br />

fuerte manipulación. Tenga cuidado con el ensamblaje del generador principal durante el<br />

transporte y el montaje.<br />

Doc No:SM-130 Iss. J 15.02.13 23 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Vientos fuertes: durante vientos fuertes el termostato incorporado al cargador eólico<br />

puede ponerse en funcionamiento para evitar que el generador se recaliente. En<br />

este modo, la salida se detendrá y la turbina se acelerará temporariamente hasta<br />

alcanzar una temperatura menor y el generador se encuentre nuevamente<br />

conectado y cargando. Se lo puede ver girar durante prolongados vientos fuertes,<br />

particularmente en temperaturas ambientales elevadas. Si es accesible y seguro,<br />

quizás prefiera sujetar temporariamente la turbina.<br />

Es esencial respetar la polaridad correcta al conectar el cargador eólico y todos los<br />

demás componentes en un circuito eléctrico. Una conexión inversa dañará al<br />

cargador eólico y la instalación incorrecta anulará la garantía.<br />

Ajuste el fusible incluido para proteger el sistema.<br />

El cargador <strong>Rutland</strong> <strong>913</strong> es apropiado para barcos de vela y algunas aplicaciones<br />

terrestres. Cuando se pronostica una tormenta de viento, se puede sujetar la<br />

turbina para minimizar el desgaste y daño particularmente cuando se encuentra<br />

instalada en aplicaciones terrestres en donde normalmente se recomiendan los<br />

modelos de cargadores eólicos Furlmatic. Tenga en cuenta que cuando el<br />

fabricante recomienda un cargador eólico plegable, la garantía se anulará en casos<br />

de daños por tormenta.<br />

6 x paletas y<br />

24 x 10x25<br />

torniillos<br />

1 x Cubierta<br />

1 x Adaptador del<br />

poste<br />

1 x Eje del generador<br />

1 x <strong>Co</strong>no de nariz y 3 x tornillos<br />

Doc No:SM-130 Iss. J 15.02.13 24 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Guía rápida de inicio – 12 pasos<br />

1. Elija un sitio abierto para exponer al cargador eólico a un flujo libre de viento y así evitar<br />

obstrucciones. A bordo, monte el cargador eólico por lo menos a 2,4 metros de la cubierta,<br />

en tierra por lo menos a 4 hasta 6 metros de altura. Lea toda la sección de Instalación.<br />

2. Elija un mástil de montaje con un diámetro interno de 41 mm y un diámetro externo no mayor<br />

a 48,5 mm para los primeros 0,6 mm cómo mínimo para (i) evitar daños accidentales y (ii)<br />

cumplir con las condiciones de la garantía.<br />

3. Monte un regulador de carga, del rango <strong>Marlec</strong>, sobre una superficie vertical adecuada y<br />

cerca de la batería. Siga las instrucciones proporcionadas con el regulador de carga.<br />

4. Perfore el mástil de montaje, en caso de ser necesario, para prepararlo para que tolere y<br />

sujete al cargador eólico. Vea la sección Montaje e Instalación.<br />

5. Elija un cable de dos conductores adecuado para que el cargador eólico se conecte con el<br />

regulador. De hasta 20 m, éste debería ser un área de secciones de por lo menos 2,5 mm²<br />

Es necesaria una pequeña área de sección de 4 mm² para unir el regulador a la batería.<br />

Para consultar otras distancias, vea la clasificación en Especificaciones para cables.<br />

6. <strong>Co</strong>loque el mástil de montaje ( esto puede hacerlo en el piso antes de levantar el mástil) de<br />

tal manera que el cable seleccionado pueda enroscarse a lo largo del mismo.<br />

7. Ajuste las paletas, la cola y la nariz del cargador eólico mediante los fijadores<br />

proporcionados. Es esencial que ajuste 4 tornillos por paleta.<br />

8. Una el cable enroscado en el mástil al cable de salida del cargador eólico mediante el bloque<br />

conector proporcionado. Envuelva con cinta aisladora. O bien utilice un tapón o toma<br />

corriente con pestillo. Le recomendamos enroscar el cable y asegurarlo con una cinta de<br />

sujeción para cables para aliviar la tensión en la junta<br />

9. <strong>Co</strong>n cuidado presione los cables hacia el mástil mientras desliza el adaptador del mástil por<br />

el mismo. Alinee los orificios y sujételos en el lugar con los tornillos y arandelas<br />

proporcionadas. Apriete con la llave Allen. No permita que la turbina gire libremente.<br />

10. Ubique el regulador de carga cerca de la batería y siga cuidadosamente TODAS las pautas<br />

y secuencias de instalación del regulador para conectar el cargador eólico a la batería.<br />

Nota: instale el fusible en línea proporcionado con el cargador eólico entre la batería y el<br />

regulador de carga.<br />

11. Asegúrese de que las conexiones de la batería sean permanentes ya que el cargador<br />

eólico NUNCA debe ponerse en funcionamiento sin estar conectado a la batería.<br />

12. Levante y sujete el cargador eólico. Ahora puede dejarlo que gire. Siga la “Lista de control<br />

final de 4 puntos denominada: Instalado y en Funcionamiento”, que se observa más<br />

adelante. También la sección “Pautas y advertencias generales” amplía sobre los puntos<br />

mencionados.<br />

Doc No:SM-130 Iss. J 15.02.13 25 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Einleitung<br />

Deutsche<br />

Wir gratulieren und bedanken uns für den Erwerb Ihres <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong>s. Wir leisten die<br />

beste Sorgfalt bei der Herstellung von allen unseren Geräten gemäß dem anerkannten<br />

Betriebsstandard ISO9001. Zur Gewährleistung für alle Vorteile beim Gebrauch von <strong>Rutland</strong> <strong>913</strong><br />

bitten wir Sie diese Anleitung vollständig durchzulesen, bevor Sie mit der Montage und<br />

Inbetriebnahme des <strong>Windcharger</strong>s fortfahren.<br />

Zusammenfassung der Funktionen und Anwendungen<br />

Aerodynamisch gestaltet für einen ausgezeichneten Luftstrom mit Luftstabilität.<br />

Das Anlassen bei einer niedrigen Windgeschwindigkeit maximiert Stromerzeugung bei geringen<br />

Windstärken.<br />

Hochwertige Baustoffe für Strapazierfähigkeit, UV-Strahlungsstabilität und<br />

Witterungsbeständigkeit.<br />

Ein Gleichstromnetzgerät zum Aufladen eines 12 oder 24 V Batteriesatzes wurde mitgeliefert.<br />

Für die Nutzung auf Segeljachten an Bord, bei Reisemobilen, Wohnmobilen und für Standorte<br />

bestimmt, wobei ein geringer Stromverbrauch für Haushaltsgeräte und auch für<br />

Navigationsgeräte etc. erforderlich ist.<br />

Anmerkung: Für weitere <strong>Windcharger</strong> von <strong>Rutland</strong>, welche für die dauerhafte Montage an Ort<br />

und Stelle entworfen wurden, treten Sie bitte mit <strong>Marlec</strong> in Kontakt oder besuchen Sie<br />

www.marlec.co.uk für weitere Informationen.<br />

Allgemeine Richtlinien & Gefahrenhinweise<br />

Die Mastmontage DARF den Außendurchmesser von 48.5mm, zumindest den Oberen von<br />

0.5m NICHT überschreiten. Größere Mastquerschnitte dürfen nicht verwendet werden, da dies<br />

zu einer geringeren Distanz zwischen dem Mast und dem Rotorblattspiels führt. Bei hohen<br />

Windbedingungen könnte es beim <strong>Windcharger</strong> zu Schaden führen, da das Rotorblatt mit dem<br />

festmontierten Mast in Kontakt kommen könnte. Ein zerbrochenes Rotorblatt verursacht ein<br />

Ungleichgewicht der Turbine und dementsprechend Schäden.<br />

Bei der Drehbewegung ist der <strong>Windcharger</strong> in der Lage Stromspannungen höher als die<br />

Nennspannung zu erzeugen. Es darf nie zugelassen werden, dass die Turbine rotiert, es sei<br />

denn das sie elektrisch mit einem Aufladekontrollgerät oder mit Batterien angeschlossen ist.<br />

Der Anschluss einer laufenden Turbine im Leerlauf an das Elektrosystem kann ernsthafte<br />

Schäden bei den Anlagebestandteilen, aufgrund der überhöhten elektrischen Spannung<br />

hervorrufen. Vorsicht ist stets zu bewahren zur Vermeidung eines Stromschlages.<br />

Das Anhalten der Turbine – wird bei der Wartung der Batterie notwendig. Falls möglich sollte<br />

die Turbine bei Bedingungen mit niedrigen Windgeschwindigkeiten gestoppt werden. Die<br />

Turbine kann durch das Rotieren oder durch das windwärts legen der Heckschaufel des<br />

Rotorblattes abgebremst werden, das führt zu einem Anhalten der Turbine, sodass sie sicher<br />

mit einem Seil an den den Mast befestigt werden kann. Vermeiden Sie, dass die Turbine für<br />

längere Zeit festgebunden bleibt, wir empfehlen stattdessen, dass die Turbine entweder<br />

abgedeckt wird, um sie gegen die Witterung zu schützen oder entfernt und in einem trockenen<br />

Raum gelagert wird. Wir empfehlen den Nutzen des <strong>Marlec</strong> Aufladekontrollgerätes mit einem<br />

integrierten Schalter zur Stromabschaltung.<br />

Wählen Sie einen windstillen Tag für die Montage der Anlage und beachten Sie dabei weitere<br />

Sicherheitsfaktoren.<br />

Es darf kein Reparaturversuch an der Anlage stattfinden, bis alle Drehbewegungen des<br />

Windgenerators gedrosselt sind.<br />

Doc No:SM-130 Iss. J 15.02.13 26 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Der <strong>Windcharger</strong> ist mit einem Keramikmagnet ausgestattet, der bei einer schwerwiegenden<br />

Handhabung beschädigt werden kann. Der Hauptstromgenerator sollte mit Sorgfalt während<br />

dem Transport und der Montage behandelt werden.<br />

Hohe Windstärken – bei hohen Windstärken kann sich das eingebaute Thermostat des<br />

<strong>Windcharger</strong>s in Betrieb setzten, um ein Überheizen des Stromgenerators zu verhindern.<br />

Während diesem Betriebszustand wird die Ausgabe des Stromgenerators beendet, das Tempo<br />

der Turbine wird sich zeitweise beschleunigen bis zu diesem Zeitpunkt, wenn die niedrigen<br />

Temperaturwerte erreicht wurden, dann wird der Stromgenerator erneut angeschlossen und<br />

aufgeladen. Dies lässt sich möglicherweise in geschlossener Reihe bei langanhaltenden<br />

hohen Windstärken ersehen, insbesondere bei hohen Außentemperaturen. Falls ein Zugriff<br />

ohne Gefahr möglich ist, wird es bevorzugt die Turbine zeitweise abzusichern.<br />

Es ist notwendig die korrekte Polarität zu beachten, wenn der <strong>Windcharger</strong> und alle weiteren<br />

Bestandteile an den elektrischen Stromkreis angeschlossen werden. Ein Rückwärtsstrom wird<br />

den <strong>Windcharger</strong> beschädigen und eine inkorrekte Installation führt dazu, dass die Garantie<br />

gegenstandslos gemacht wird.<br />

Die mitgelieferte Sicherung muss zum Schutz des Gerätes angebracht werden.<br />

Der <strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong> eignet sich für Segelboote und für einige Anwendungen zu<br />

Land. Wenn Sturmwinde vorhergesagt werden, kann die Turbine gedrosselt werden, um einen<br />

Verschleiß und Abnutzen zu reduzieren, insbesondere wenn sie für Anwendungen zu Lande<br />

installiert wurde, wobei dafür normalerweise die <strong>Windcharger</strong> der Furlmatic Modelle empfohlen<br />

werden.<br />

Anmerkung, wenn es vom Hersteller empfohlen wurde, dass ein <strong>Windcharger</strong> der Furlmatic<br />

Modelle für jegliche Art von Segelvorrichtungen zu nutzen sei, wird die Garantie im Falle eines<br />

Sturmschadens gegenstandlos gemacht.<br />

Im Zweifelsfall wenden Sie sich bitte an Ihren Fachhändler, an einen fachkundigen<br />

Elektroingenieur oder an den Hersteller.<br />

6 x Rotorblatter und<br />

24 x Schrauben<br />

1 x Haube<br />

1 x Nase und<br />

3 x Schrauben<br />

1 x Pfosten Adapter<br />

1 x Generatornabe<br />

Doc No:SM-130 Iss. J 15.02.13 27 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Kurzanleitung mit zwölf Anhaltspunkten<br />

1. Wählen sie eine offene Stelle für die Montage Ihres <strong>Windcharger</strong>s in einem bestimmten<br />

Luftstrom und unter der Vermeidung von Hindernissen. An Bord sollte der <strong>Windcharger</strong><br />

mindestens 2.4 Meter über dem Deck und zu Lande mindestens 4 - 6 Meter hoch<br />

angebracht werden. Lesen Sie den vollständigen Absatz zu: An einer Stelle befestigen<br />

[Siting].<br />

2. Wählen Sie einen Mast mit einem Innendurchmesser von 41.0mm und einem<br />

Außendurchmesser von nicht größer als 48.5 mm und mindestens für den Oberen 0.6m,<br />

um (i)einen Nebenschaden zu vermeiden und (ii) die Bedingungen der Garantie zu erfüllen.<br />

3. Montieren sie eines der Aufladekontrollgeräte von der Firma <strong>Marlec</strong> an eine geeignete<br />

senkrechte Oberfläche und in der Nähe der Batterie. Befolgen Sie die Anleitung, die mit<br />

dem Aufladekontrollgerät mitgeliefert wurde.<br />

4. Bohren Sie, falls erforderlich, in den Montagemast zur Vorbereitung der Befestigung und<br />

Inbetriebnahme des <strong>Windcharger</strong>s. Siehe Montage und Installation [Assembly and<br />

Installation].<br />

5. Wählen sie ein geeignetes zweiadriges Kabel für den Anschluss des <strong>Windcharger</strong>s zum<br />

Aufladekontrollgerät. Bis zu 20 Meter, dies sollte mindestens von einer 2.5mm²<br />

Querschnittsfläche sein. Ein Kurzabschnitt von einer 4mm² Querschnittsfläche ist für die<br />

Verbindung zwischen dem Aufladekontrollgerät und der Batterie erforderlich. Für weitere<br />

Abstände beziehen Sie sich bitte auf die Tabelle Kabelspezifikationen [Cable<br />

Specifications].<br />

6. Bringen Sie den Montagemast in eine bestimmte Stellung, sodass das gewählte Kabel<br />

aufgezogen werden kann, das kann auch auf dem Boden durchgeführt werden, bevor sie<br />

den Mast anheben.<br />

7. Die Rotorblätter, das Heck- und Vorderteil an den <strong>Windcharger</strong> mit den mitgelieferten<br />

Befestigungsteilen montieren. Wichtig ist, dass 4 Schrauben pro Rotorblatt angebracht<br />

werden.<br />

8. Schließen Sie das durchgezogene Kabel am Mast mit dem Kabelausgang des<br />

<strong>Windcharger</strong>s mit der mitgelieferten Anschlussleiste an und mit Isolierband umwickeln. Es<br />

kann als Alternative eine einklinkende Steckvorrichtung verwendet werden. Wir empfehlen<br />

das Kabel zurückzuschlingen, um es mit einem Kabelbinder zu befestigen und eine<br />

Zugentlastung am Verbindungsstück zu erzielen.<br />

9. Die Kabel mit Sorgfalt am Mast hinunter schieben, während das Passstück am Mast<br />

herunter gegleitet wird. Die Löcher in eine Reihe bringen und an der Stelle mit den<br />

mitgelieferten Schrauben und Muttern befestigen und mit dem Sechskantstiftschlüssel<br />

befestigen. Die Turbine darf nicht sich nicht unbehindert im Kreis drehen.<br />

10.Das Aufladekontrollgerät neben der Batterie lokalisieren und mit Sorgfalt ALLE Richtlinien<br />

und Installationsanweisungen für den Anschluss an den <strong>Windcharger</strong> bis durch zur Batterie<br />

befolgen. Anmerkung: installieren Sie die mitgelieferte In-line Sicherung mit dem<br />

<strong>Windcharger</strong> zwischen der Batterie und dem Aufladekontrollgerät.<br />

11.Sicherstellen, dass die Batterieanschlüsse dauerhaft sind, da der <strong>Windcharger</strong> NIE ohne<br />

einen Anschluss mit der Batterie in Betrieb genommen werden darf.<br />

12.Den <strong>Windcharger</strong> anheben und befestigen. Die Drehbewegungen können nun durchgeführt<br />

werden. Befolgen sie die im folgenden erläuterte “Inbetriebnahme – 4-Punkte<br />

Überprüfliste“. [Up and Running- Four Points Final Checklist], ebenso die “Allgemeinen<br />

Richtlinien und Gefahrenhinweise”, die sich auf die obengenannten Punkte beziehen.<br />

Doc No:SM-130 Iss. J 15.02.13 28 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

For Your Records<br />

For your future reference we recommend you note the following:<br />

Serial Number:<br />

Date of Purchase:<br />

Date of Installation:<br />

Type of Regulator:<br />

Doc No:SM-130 Iss. J 15.02.13 29 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Doc No:SM-130 Iss. J 15.02.13 30 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd

<strong>Rutland</strong> <strong>913</strong> <strong>Windcharger</strong><br />

Installation & Operation<br />

Limited Warranty<br />

The <strong>Marlec</strong> <strong>Engineering</strong> <strong>Co</strong>mpany Limited Warranty provides free replacement<br />

cover for all defects in parts and workmanship for 24 months from the date of<br />

purchase. <strong>Marlec</strong>'s obligation in this respect is limited to replacing parts, which<br />

have been promptly reported to the seller and are in the seller’s opinion defective<br />

and are so found by <strong>Marlec</strong> upon inspection. A valid proof of purchase will be<br />

required if making a warranty claim.<br />

Defective parts must be returned by prepaid post to the manufacturer <strong>Marlec</strong><br />

<strong>Engineering</strong> <strong>Co</strong>mpany Limited, <strong>Rutland</strong> House, Trevithick Road, <strong>Co</strong>rby,<br />

Northamptonshire, NN17 5XY, England, or to an authorised <strong>Marlec</strong> agent.<br />

This Warranty is void in the event of improper installation, owner neglect,<br />

misuse, damage caused by flying debris or natural disasters including lightning<br />

and hurricane force winds. This warranty does not extend to support posts,<br />

inverters, batteries or ancillary equipment not supplied by the manufacturer.<br />

No responsibility is assumed for incidental damage. No responsibility is<br />

assumed for consequential damages. No responsibility is assumed for damage<br />

caused by user modification to the product or the use of any unauthorised<br />

components.<br />

No responsibility is assumed for use of a non "furling" versions of the <strong>Rutland</strong><br />

<strong>Windcharger</strong> where <strong>Marlec</strong> or one of its authorised agents finds that a generator<br />

incorporating a furling device should have been used.<br />

Manufactured in the UK by<br />

<strong>Marlec</strong> <strong>Engineering</strong> <strong>Co</strong> Ltd<br />

<strong>Rutland</strong> House,<br />

Trevithick Rd,<br />

<strong>Co</strong>rby, Northants,<br />

NN17 5XY UK<br />

Tel: +44 (0)1536 201588 Fax: +44 (0)1536 400211<br />

Email: sales@marlec.co.uk<br />

www.marlec.co.uk<br />

Doc No:SM-130 Iss. J 15.02.13 31 <strong>Marlec</strong> Eng <strong>Co</strong> Ltd